An air crush structure

An air-type, sliding mechanism technology, applied in steering mechanisms, vehicle components, steering columns, etc., can solve problems such as no damping, little space for improving collision performance, and falling parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

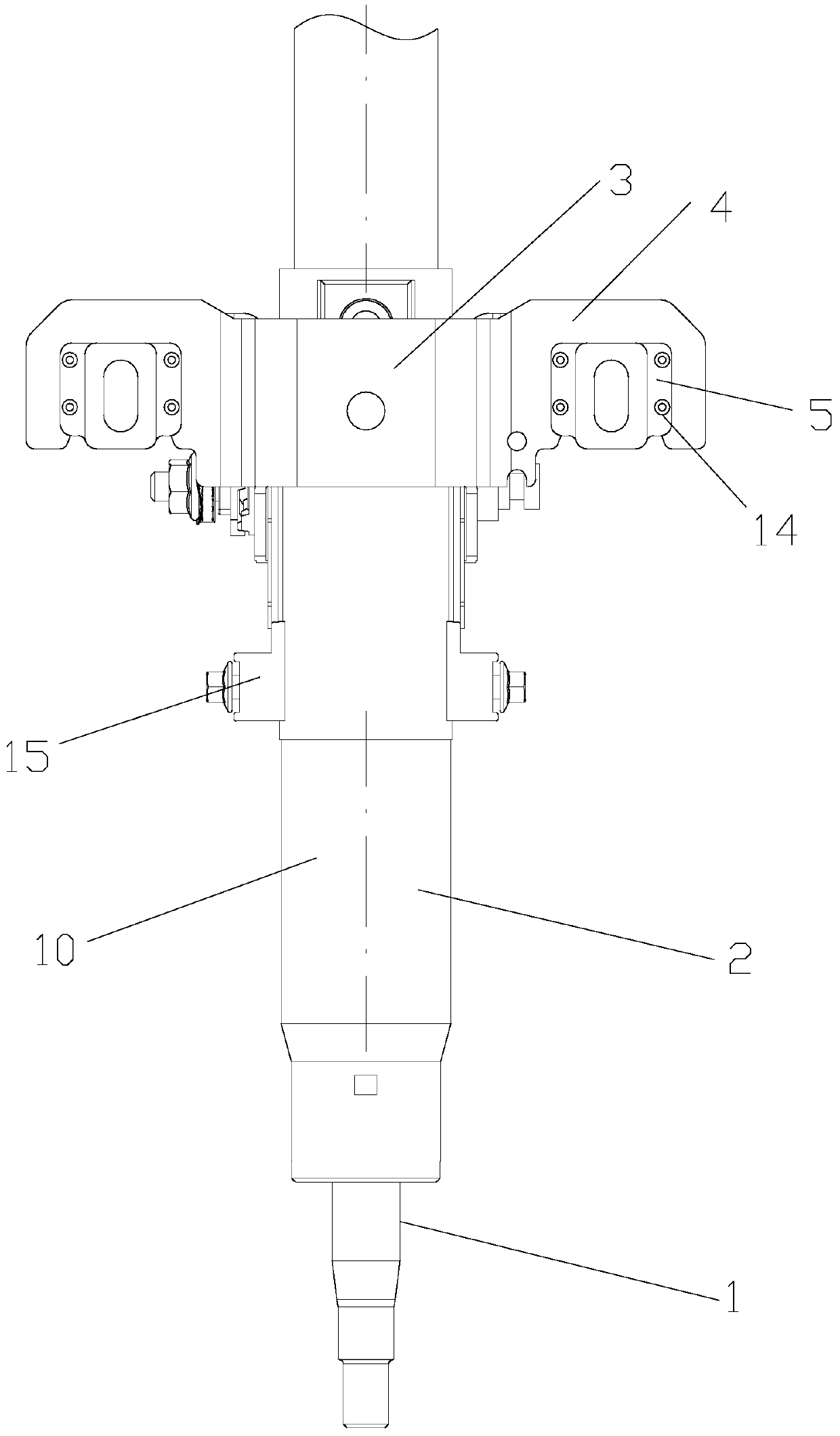

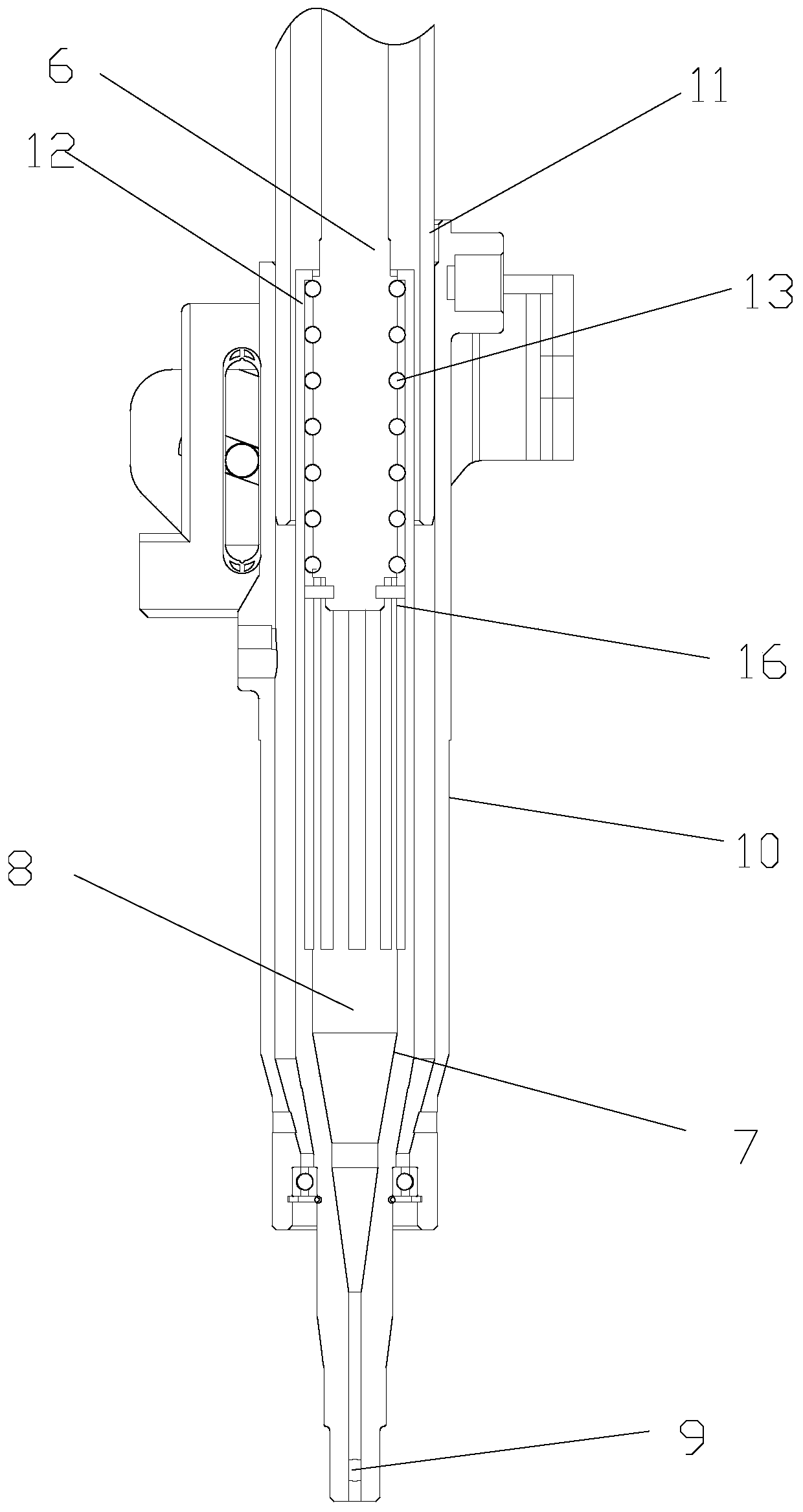

[0021] Such as Figure 1-3 The novel air crushing structure includes a steering column and an outer bushing 2 of the steering column, the outer bushing 2 of the steering column is connected with a connecting bracket 3, and mounting seats are provided on both sides of the connecting bracket 3 4. The mounting base 4 is connected with a shear block 5, and the mounting base 4 is provided with a connection hole 14, and the connection hole 14 is connected with the shear block 5 after injection molding.

[0022] The steering column includes a lower shaft 6 and an upper shaft 7. A closed flexible airtight container 8 is formed inside the upper shaft 7. Compressed air is added into the flexible airtight container 8. The top of the flexible airtight container 8 of the upper shaft 7 An adjustable pressure relief valve 9 is provided, and both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com