Feeding-discharging and glass detection manipulator of hot bending machine

A glass inspection and manipulator technology, applied in manipulators, chucks, manufacturing tools, etc., can solve problems such as fatigue and inability to meet the technical beat requirements of hot bending machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

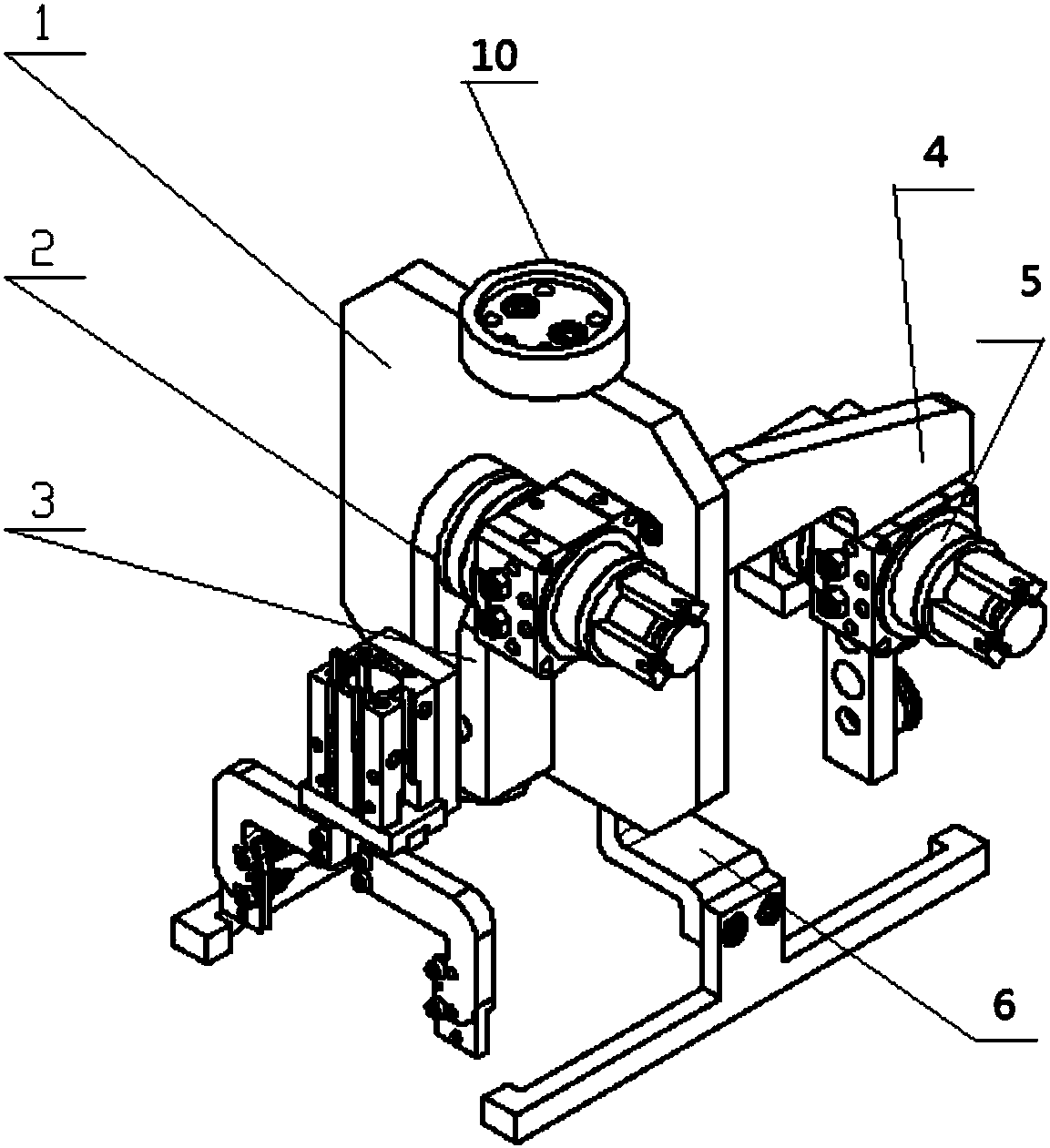

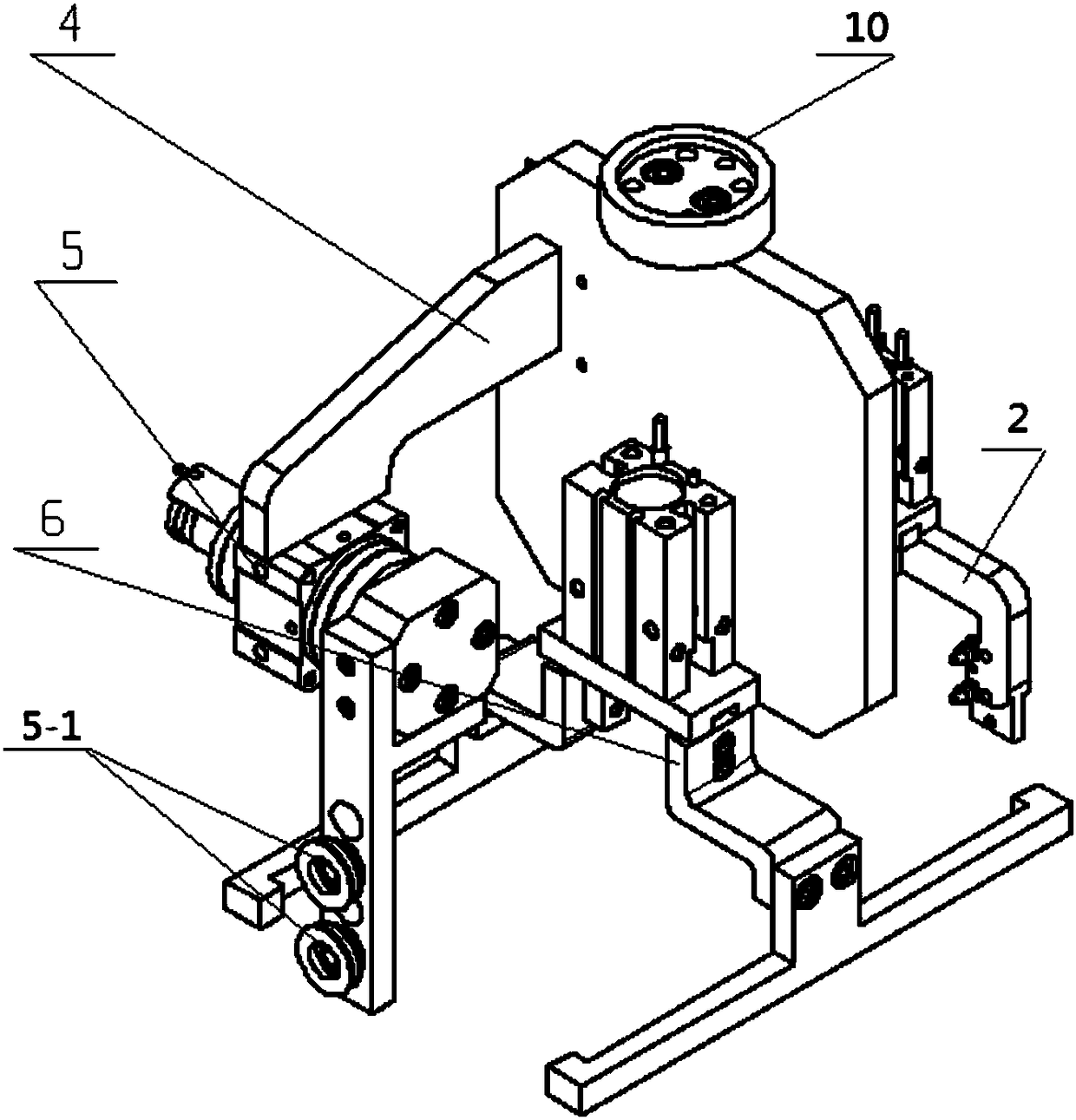

[0017] Specific implementation mode 1: Combination Figure 1 to Figure 5 Detailed description of this embodiment, this embodiment is a hot bending machine loading and unloading and glass inspection manipulator, including a main body (1), a manipulator connector (10), a clamping assembly (2), a cantilever support (4), and a suction assembly ( 5) and grabbing components (6);

[0018] The body (1) is a plate-shaped body, the manipulator connector (10) is fixed on the edge of the upper end plate of the body (1), the clamping assembly (2) is arranged on a plate surface of the body (1), and the cantilever support (4), The suction component (5) and the grasping component (6) are arranged on the other board surface of the body (1);

[0019] The clamping assembly (2) is composed of a clamping part and a swinging part. The clamping part realizes the action of clamping and releasing the glass sheet. The swinging part realizes the driving of the clamping part in the hanging station or the sid...

specific Embodiment approach 2

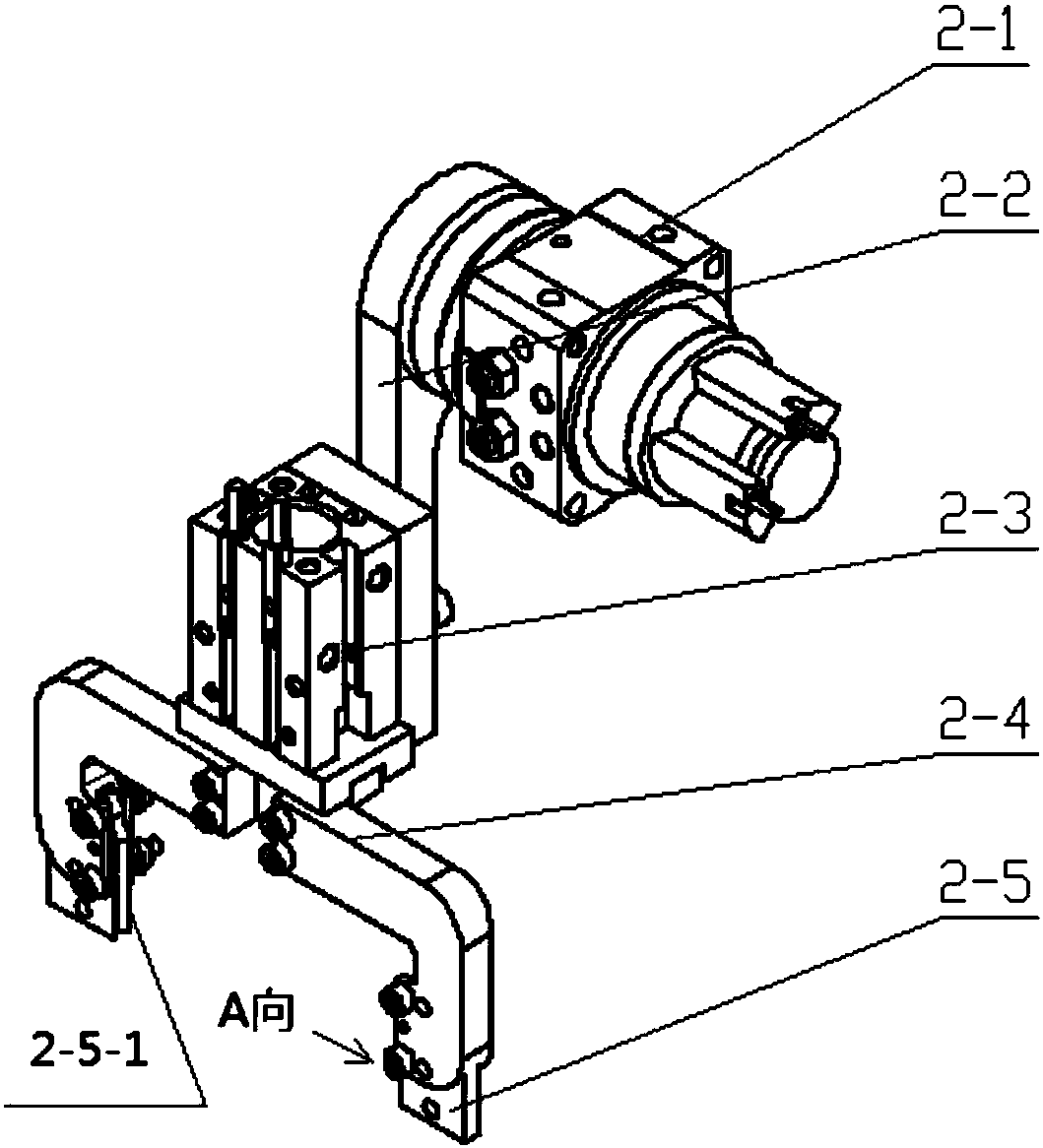

[0023] Specific implementation manner two: combination image 3 This embodiment will be described in detail. This embodiment is a further description of the material loading and unloading and glass inspection manipulator of a hot bending machine described in the first embodiment. In this embodiment, the swinging part in the clamping assembly (2) includes a swing cylinder (2-1) and Connecting frame (2-2), the clamping parts include pneumatic clamping fingers (2-3), clamping jaws (2-4) and protective pads (2-5); one end of the connecting frame (2-2) is fixed to the swing cylinder On the rotating part of (2-1), the other end of the connecting frame (2-2) is fixed on the shell of the pneumatic gripper (2-3), and the gripper (2-4) is fixed on the pneumatic gripper (2). On the pneumatic part of -3), the protective pad (2-5) is fixed on the front end of the clamping jaw (2-4). The pneumatic clamping fingers (2-3) drive the clamping jaws (2-4) and the protective pad (2-5) to complete ...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination Figure 4 This embodiment will be described in detail. This embodiment is a further description of the loading and unloading and glass inspection manipulator of a hot bending machine described in the first embodiment. In this embodiment, the suction assembly consists of a swing cylinder (5-1) and a connecting plate (5-2). , The adapter frame (5-3) and the suction cup (5-4) are composed; the connecting plate (5-2) is fixed with the rotating part of the swing cylinder (5-1), one end of the adapter frame (5-3) It is fixed on the connecting plate (5-2), and the suction cup (5-4) is arranged on the other end of the adapter frame (5-3).

[0026] The turning angle of the sucker (5-4) is completed by the swing cylinder (5-1) driving the connecting plate (5-2) and the adapter frame (5-3).

[0027] The invention completes the suction and placement of the glass through the combined control of the swing cylinder and the suction cup, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com