Iron pot edge bur automatic treating device used for iron pot production line

An edge burr and automatic processing technology is applied in the field of iron pot edge burr automatic processing devices for iron pot production lines, and can solve the problems of affecting the qualification rate of iron pots, inconvenience, and troublesome process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

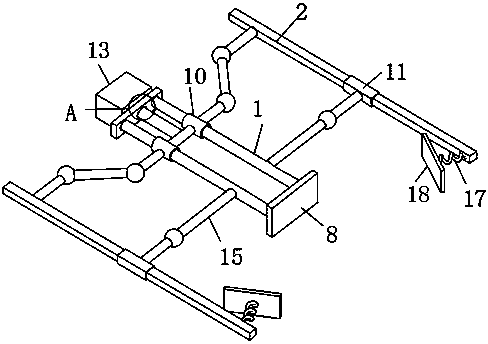

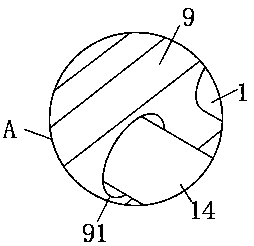

[0021] An automatic processing device for iron pan edge burrs for an iron pan production line, comprising a center guide rod 1 and a positioning top plate 8, one side of the positioning top plate 8 is symmetrically and vertically welded with a center guide rod 1, and the end of the center guide rod 1 is far away from the positioning top plate 8 The positioning end plate 9 is fixedly installed, and the surface of the center guide rod 1 is movably covered with a first sliding sleeve 10, and a sleeve rod 12 is welded between adjacent first sliding sleeves 10, and one side of the positioning end plate 9 is fixed. A power machine 13 is installed, and one end of the power machine 13 is rotatably connected to a telescopic rod 14. One end of the telescopic rod 14 penetrates the positioning end plate 9 and is fixedly connected to the surface of the sleeve rod 12. The outer surface of the first sliding sleeve 10 is provided with a first connection Rod 3, second connecting rod 4 and third...

Embodiment 2

[0023] An automatic processing device for iron pan edge burrs for an iron pan production line, comprising a center guide rod 1 and a positioning top plate 8, one side of the positioning top plate 8 is symmetrically and vertically welded with a center guide rod 1, and the end of the center guide rod 1 is far away from the positioning top plate 8 The positioning end plate 9 is fixedly installed, and the surface of the center guide rod 1 is movably covered with a first sliding sleeve 10, and a sleeve rod 12 is welded between adjacent first sliding sleeves 10, and one side of the positioning end plate 9 is fixed. A power machine 13 is installed, and one end of the power machine 13 is rotatably connected to a telescopic rod 14. One end of the telescopic rod 14 penetrates the positioning end plate 9 and is fixedly connected to the surface of the sleeve rod 12. The outer surface of the first sliding sleeve 10 is provided with a first connection Rod 3, second connecting rod 4 and third...

Embodiment 3

[0026] An automatic processing device for iron pan edge burrs for an iron pan production line, comprising a center guide rod 1 and a positioning top plate 8, one side of the positioning top plate 8 is symmetrically and vertically welded with a center guide rod 1, and the end of the center guide rod 1 is far away from the positioning top plate 8 The positioning end plate 9 is fixedly installed, and the surface of the center guide rod 1 is movably covered with a first sliding sleeve 10, and a sleeve rod 12 is welded between adjacent first sliding sleeves 10, and one side of the positioning end plate 9 is fixed. A power machine 13 is installed, and one end of the power machine 13 is rotatably connected to a telescopic rod 14. One end of the telescopic rod 14 penetrates the positioning end plate 9 and is fixedly connected to the surface of the sleeve rod 12. The outer surface of the first sliding sleeve 10 is provided with a first connection Rod 3, second connecting rod 4 and third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com