Method for manufacturing pressing dies for ship curved plate pressing forming process

A technology of stamping forming and curved panels, which is applied in the field of stamping dies for manufacturing ship curved panels, which can solve the problems of complex casting die manufacturing process, heavy use, and long production cycle, so as to shorten the production cycle and reduce production costs. cost, making accurate and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples. For the experimental methods that do not specify specific conditions in the following examples, select according to conventional methods and conditions, or according to the product instructions.

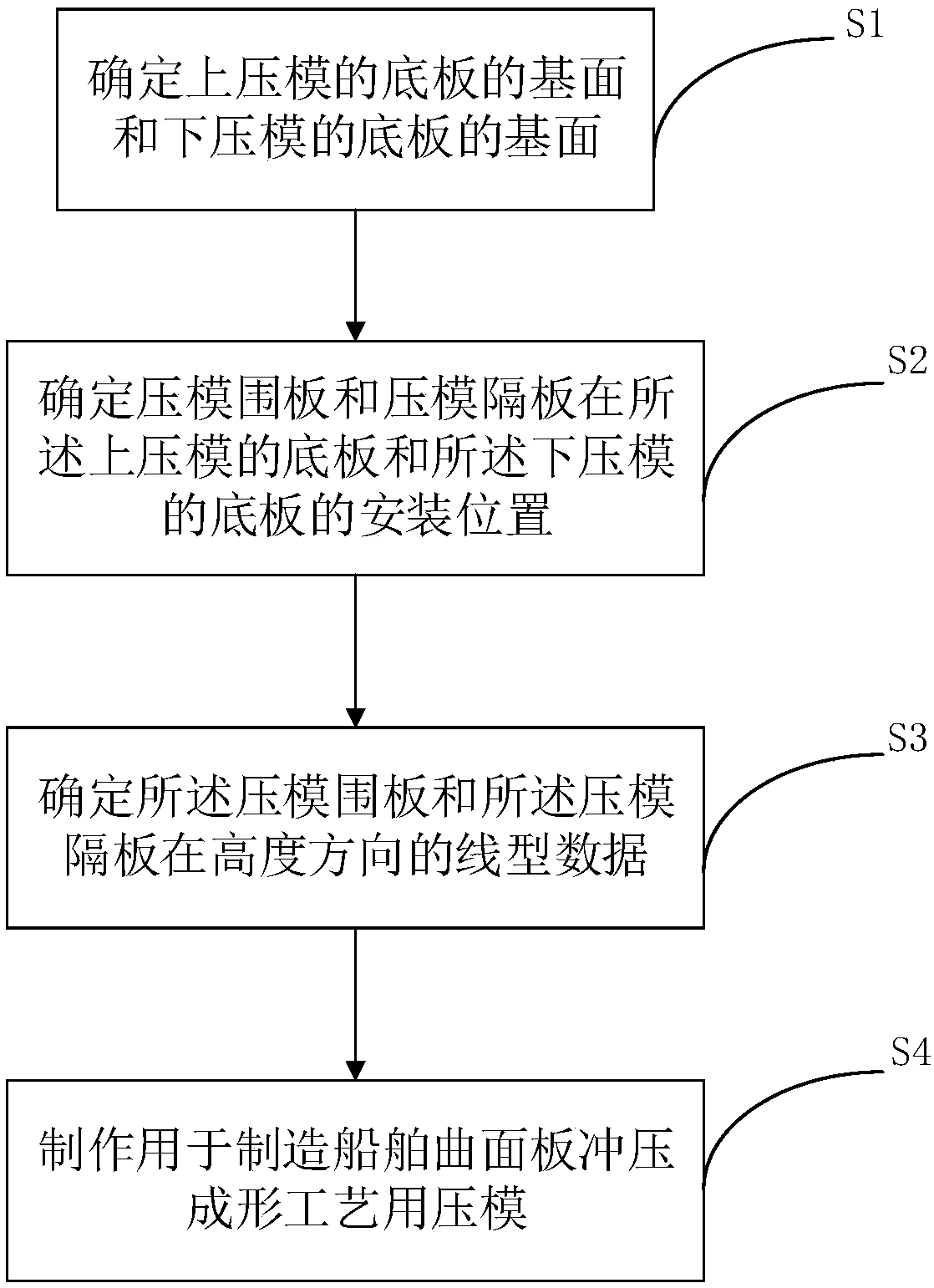

[0036] refer to figure 1 , the present invention is a kind of method that is used to manufacture the die for ship curved panel stamping forming process, it is characterized in that, it comprises the following steps:

[0037] Step S1. Determine the base surface of the bottom plate of the upper die and the base surface of the bottom plate of the lower die: according to the optimal force direction and pressure of the curved die surface of the upper die and the curved die face of the lower die The center position determines the processing reference plane, and the processing reference plane is used as the base surface of the bottom plate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com