Mesoporous silica matrix composite microsphere with efficient coagulation function and preparation method thereof

A technology of mesoporous silica and composite microspheres, which is applied in the field of biomedical materials, can solve the problems affecting hemostasis, tissue repair performance, damage to the health of workers, adhesion and blocking of bleeding sites, etc., and achieves the preparation cycle The effect of shortening, eliminating polluting dust and sealing adhering wounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

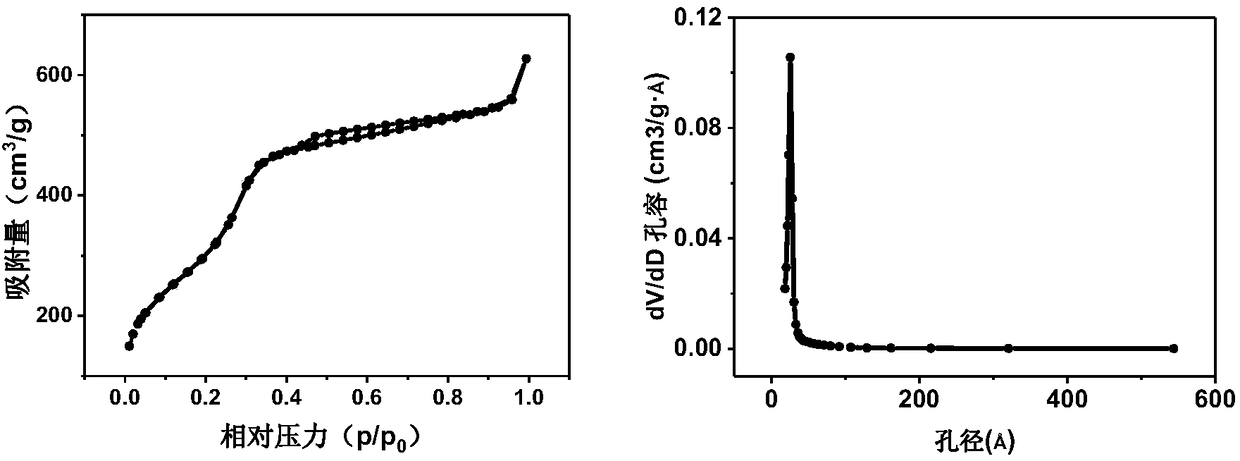

[0054] The specific preparation process includes preparation of mesoporous powder, microsphere molding and drying steps.

[0055] Powder preparation: Dissolve silicon sources such as ethyl orthosilicate or sodium silicate and surfactants in 1-10% hydrochloric acid / ammonia aqueous solution, the pH value of the system is 1-12, and the temperature is controlled at 30-60°C, 100 Stirring at -200 rpm for 2-6 hours, the solution undergoes solification and then gelation to form a gel, the gel is collected by suction filtration and then calcined to remove the surfactant to form a mesoporous structure.

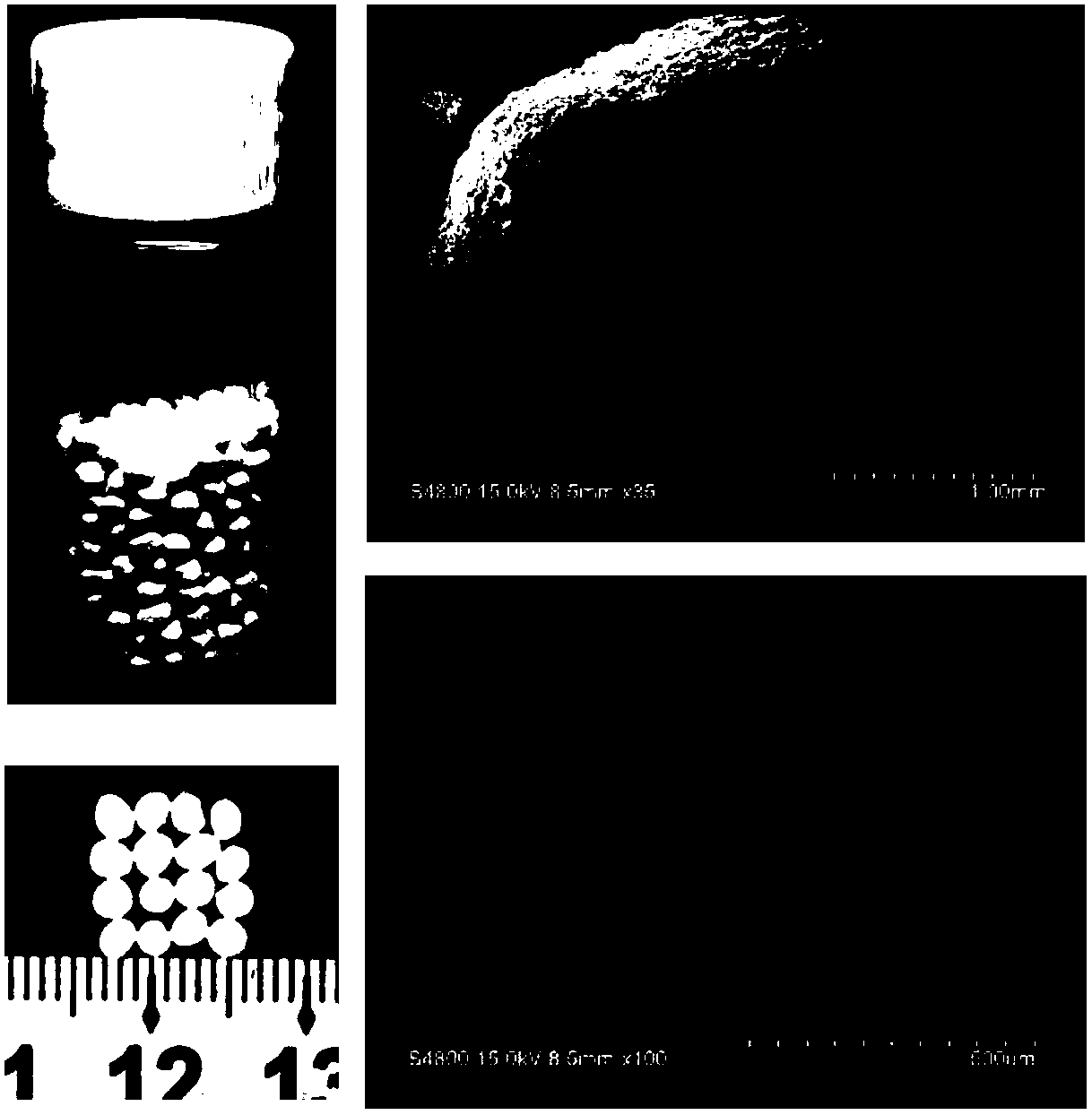

[0056] Microsphere molding: According to the type of granulating agent, determine the amount of mesoporous silicon powder and the type and amount of foaming pore-forming agent, mix the above ingredients with water; and add dropwise at a speed of 30-90 drops / min In the acidic or alkaline solution, through the interaction between the natural polysaccharide and the foaming pore-forming age...

Embodiment 1

[0090] This example relates to the synthesis of mesoporous silica powder

[0091] Prepare 280mL of 3% hydrochloric acid aqueous solution, add 1.24g of surfactant P123, stir until clear, pH value is 2-4, add 18.37mL tetraethyl orthosilicate TEOS dropwise, stir at 60°C and 500 rpm for 2h, the reaction is over Afterwards, the sample was collected by filtration, and calcined in a muffle furnace at 600° C. for 6 hours to obtain a mesoporous silica powder.

Embodiment 2

[0093] This example relates to the synthesis of mesoporous silica powder

[0094] Prepare 280mL of 5% aqueous ammonia solution, add 1.08g of cetyltrimethylammonium bromide (CTAB), stir until clear, the pH value is 8-10, add 18.37mL of ethyl orthosilicate TEOS drop by drop, 60℃ Stir at 500 rpm for 2 hours, collect the sample by filtration after the reaction, and calcinate in a muffle furnace at 600° C. for 6 hours to obtain mesoporous silica powder.

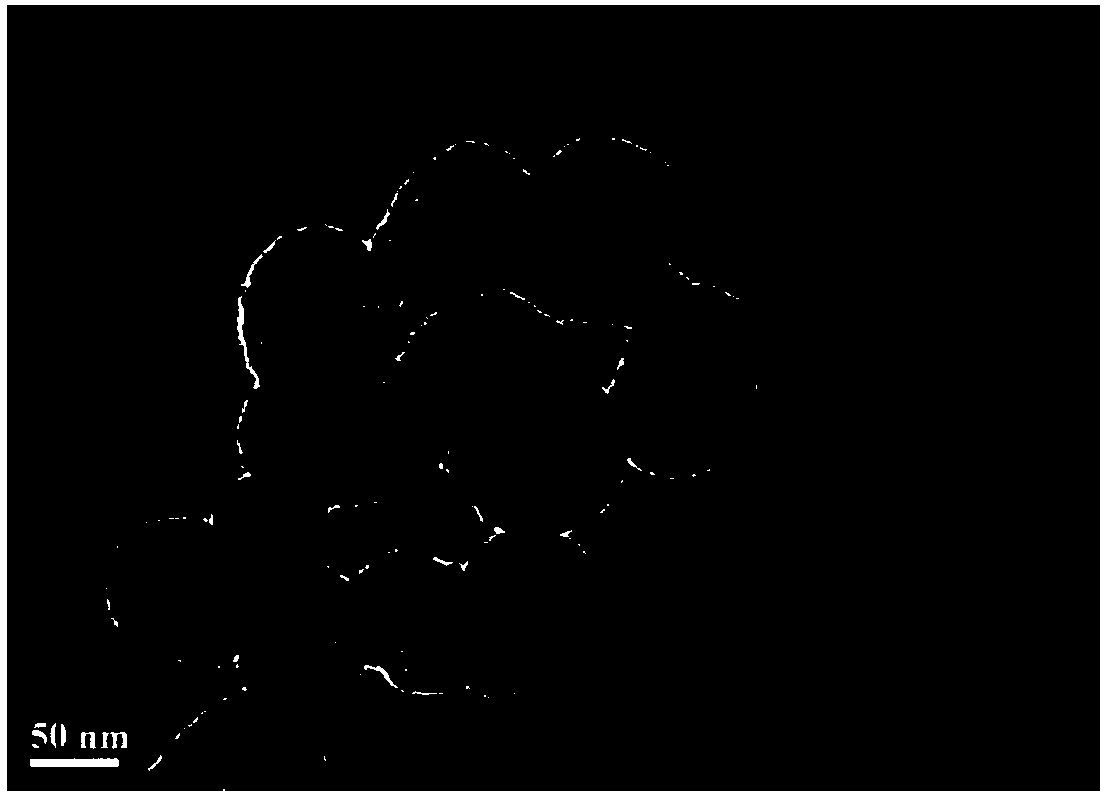

[0095] Use a transmission electron microscope (HRTEM, JEM-2100, Japan) to observe the prepared mesoporous silica powder morphology and mesoporous structure, the results are as follows figure 1 It is shown that the prepared silica powder has an ordered mesoporous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com