Hulless barley konjac nutritive paste and making method thereof

A technology of nutrient paste and konjac is applied in the field of health care products, which can solve the problems of nutrient loss and poor taste, and achieve the effects of low cost, low calorie and rich edible value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

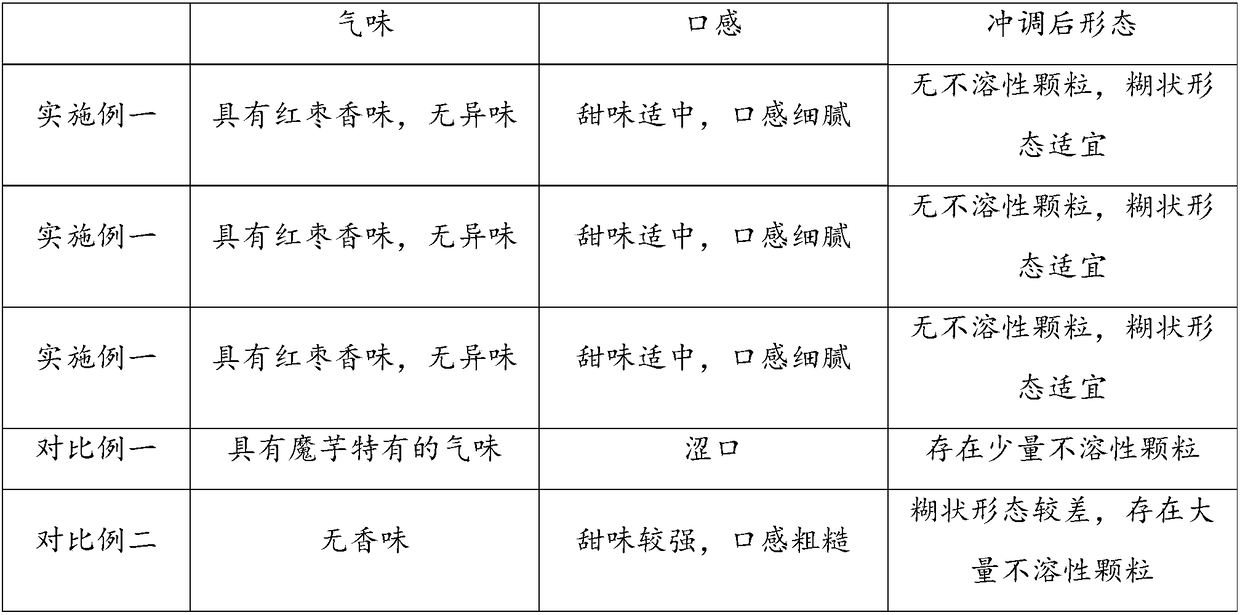

Examples

Embodiment 1

[0025] Mix the following components evenly according to the mass ratio:

[0026] 400 parts of highland barley powder, 80 parts of konjac powder, 160 parts of red date powder, 40 parts of lotus seed powder, 120 parts of barley powder, and 200 parts of rock sugar.

[0027] The processing steps are as follows:

[0028] (a) Take highland barley with a moisture content of less than 50%, and ripen it with microwaves. During the ripening process, the microwave power is 900W, the ripening temperature is 60°C, and the ripening time is 20min;

[0029] (b) Konjac, jujube, lotus seeds and coix seed were subjected to low-temperature microwave drying treatment. During the drying process, the microwave power was 1000W, the drying temperature was 40°C, and the drying time was 24h;

[0030] (c) deodorize the konjac flour obtained in step (b) with microwaves; the microwave power is 1200W, the treatment temperature is 50°C, and the treatment time is 2min.

[0031] (d) Pulverize the rock sugar ...

Embodiment 2

[0035] Mix the following components evenly according to the mass ratio:

[0036] 400 parts of highland barley powder, 40 parts of konjac powder, 100 parts of red date powder, 30 parts of lotus seed powder, 80 parts of barley powder, and 180 parts of rock sugar.

[0037] The processing steps are as follows:

[0038] (a) Take highland barley with a moisture content of less than 50%, and ripen it with microwaves. During the ripening process, the microwave power is 900W, the ripening temperature is 60° C., and the ripening time is 15 minutes;

[0039] (b) Konjac, jujube, lotus seeds and coix seed were subjected to low-temperature microwave drying treatment. During the drying process, the microwave power was 800W, the drying temperature was 45°C, and the drying time was 16 hours;

[0040] (c) deodorize the konjac flour obtained in step (b) with microwaves; the microwave power is 1000W, the processing temperature is 50°C, and the processing time is 5min.

[0041] (d) Pulverize the...

Embodiment 3

[0045] Mix the following components evenly according to the mass ratio:

[0046] 600 parts of highland barley powder, 80 parts of konjac powder, 100 parts of red date powder, 30 parts of lotus seed powder, 80 parts of barley powder, and 180 parts of rock sugar.

[0047] The processing steps are as follows:

[0048] (a) Take highland barley with a moisture content of less than 50%, and ripen it with microwaves. During the ripening process, the microwave power is 900W, the ripening temperature is 65° C., and the ripening time is 10 minutes;

[0049] (b) Konjac, jujube, lotus seeds and coix seed were subjected to low-temperature microwave drying treatment. During the drying process, the microwave power was 1000W, the drying temperature was 45°C, and the drying time was 10h;

[0050] (c) deodorize the konjac powder obtained in step (b) with microwaves; the microwave power is 1000W, the processing temperature is 55°C, and the processing time is 3min.

[0051] (d) Pulverize the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com