Housing, high pressure tank and method for operating high pressure tank

A technology of high-pressure tanks and shells, which is applied to the parts of X-ray tubes, X-ray tube shells/containers, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

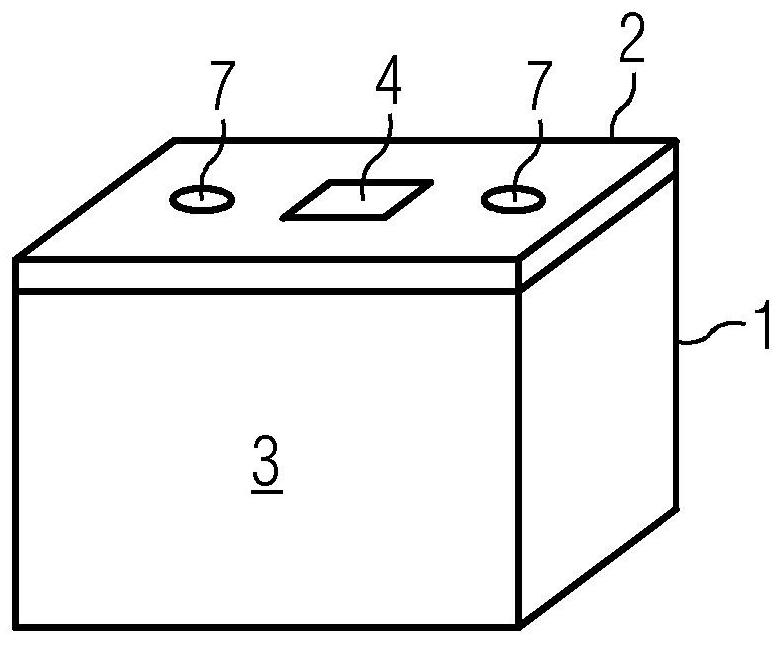

[0031] figure 1 An oblique view of the housing of the high-pressure tank is shown, which is used to generate high pressure. The housing has an upwardly open boiler 1 which is sealed in a pressure-tight manner by a circuit board cover 2 . In particular, the high voltage transformer in insulating oil 3 is located inside the housing. A strain gauge 4 is glued to the circuit board cover 2 and connected to a test circuit (not shown). figure 1 Inadmissible positive pressure in the housing is not indicated. The circuit board cover 2 is flat without arching or deformation. The compensation membrane 7 for pressure compensation is not stressed.

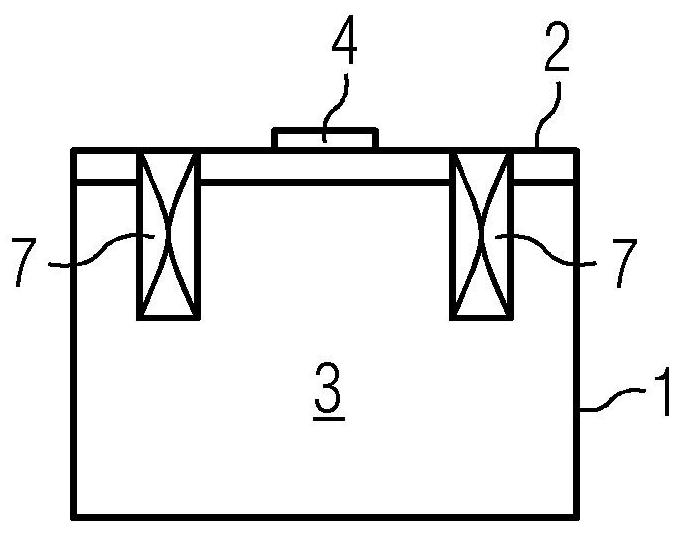

[0032] figure 2 shows the basis figure 1 The cross-section of the housing where the insulating oil 3 inside the boiler 1 expands due to the temperature rise and has completely compressed the compensating membrane 7 . The pressure inside the housing is so great that the circuit board cover 2 bows outwards, thus causing the strain gauges ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com