Insulating layer coating device for cables

A technology of coating device and insulating layer, applied in the direction of conductor/cable insulation, cable/conductor manufacturing, circuit, etc., can solve the problem of wire core offset, etc., achieve smooth cable, tight bonding, and avoid wire core eccentricity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below by means of specific embodiments:

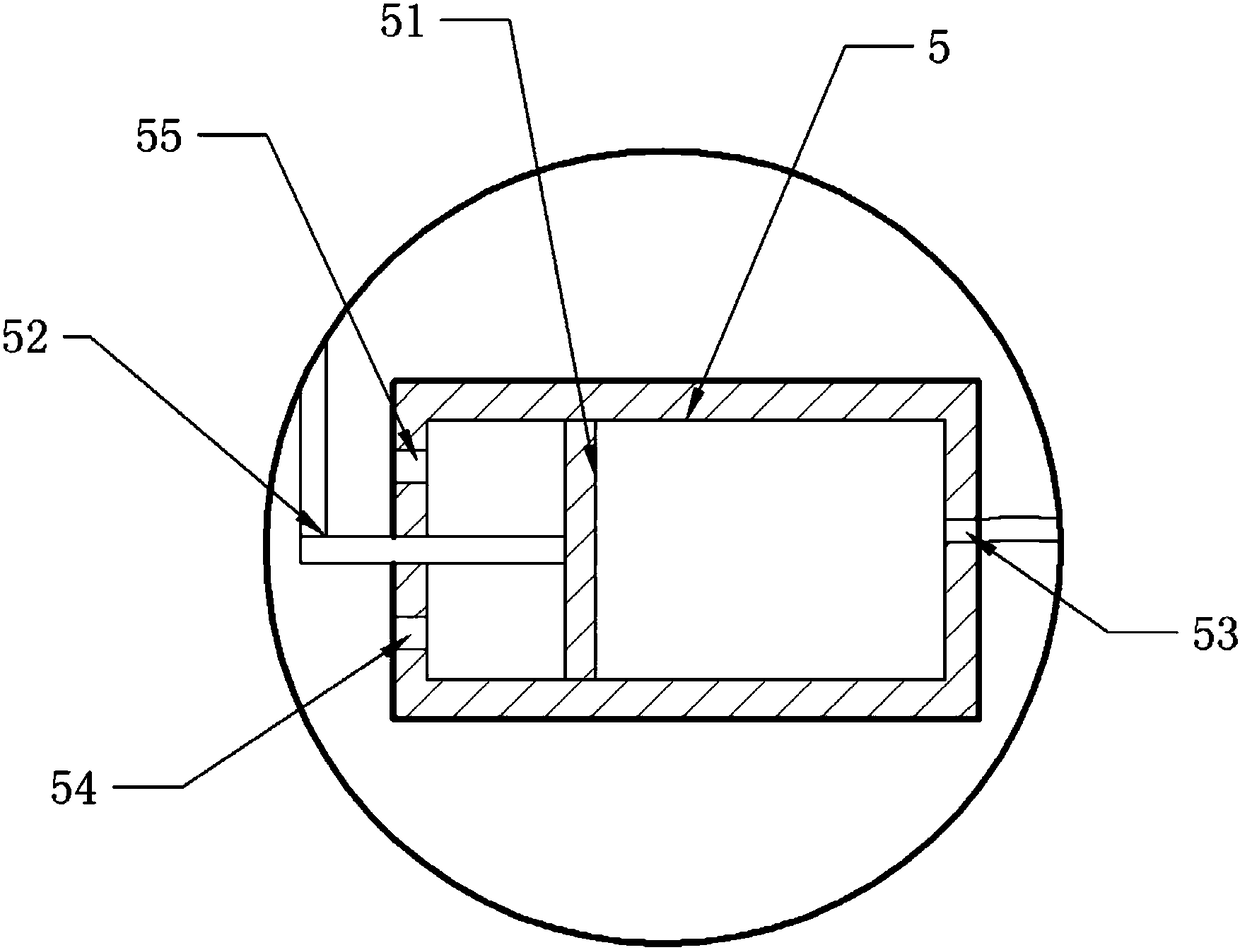

[0031] The reference signs in the drawings of the specification include: rubberized block 1, through hole 11, feed port 12, feed hole 13, adjustment block 2, adjustment hole 21, guide section 211, forming section 212, pressure tank 22, feed Air hole 23, pressure plate 3, baffle plate 4, piston barrel 5, piston 51, L-shaped rod 52, air outlet 53, air suction port 54, exhaust port 55, grinding block 6, rotating blade 61, extrusion mechanism 7, Unwinding roller 8, winding roller 9, chute 91.

[0032] Such as figure 1 As shown, the insulating layer coating device of the cable includes a frame and a winding roller 9, an adjustment block 2, a rubberized block 1 and an unwinding roller 8 arranged on the frame from top to bottom in sequence, and the winding roller 9 and The unwinding roller 8 is all rotatably connected on the frame. Tension pulleys are rotatably connected betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com