Device for measuring change of pressure drop in burning period of cigarette in real time and method thereof

A technology for real-time measurement and internal pressure, applied in chemical analysis by combustion, etc., can solve problems such as lack of further research, achieve good repeatability, deepen cognition, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

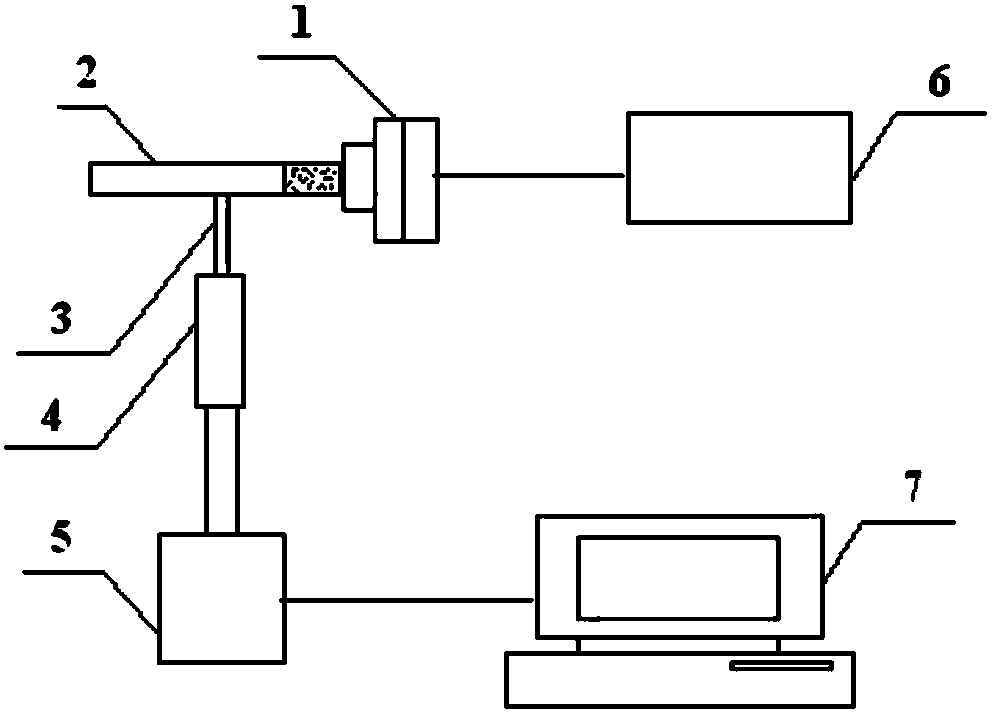

[0041]In this embodiment, the tubular pressure probe 3 is a hollow stainless steel tube with a length of 40 mm, an inner diameter of 1.0 mm, and an outer diameter of 1.1 mm. The tubular joint 4 is a threaded stainless steel casing with an inner diameter of 1.1 mm and a length of 30 mm. One end of the tubular joint 4 is threaded on the pressure sensor of the pressure measurement system 5, specifically connected to the detection end of the pressure sensor. The response frequency of the pressure measurement system 5 is 3KHz, the range is -6KPa, and the data acquisition frequency is 100Hz.

[0042] The above-mentioned device is used for measurement and evaluation, and the process is as follows:

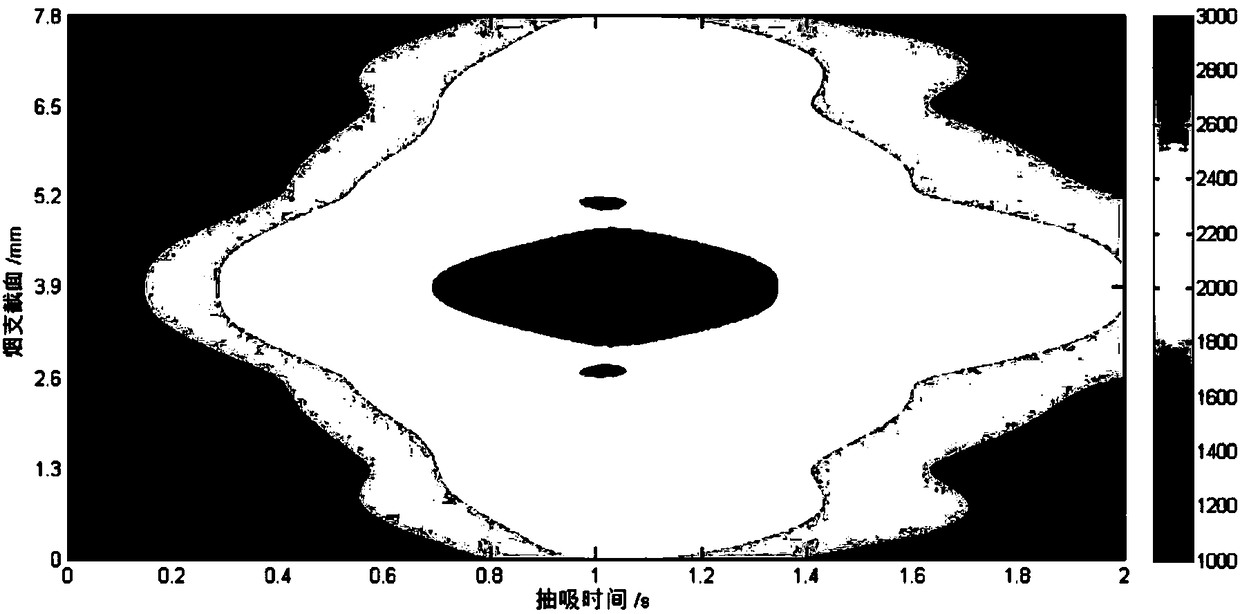

[0043] Select a certain brand of conventional cigarette 2 for testing, and first carry out air leakage inspection and suction capacity correction on the cigarette smoking system 6 according to the conditions stipulated in the national standard GB / T16450-2004; 58s puffing parameters Smoke...

Embodiment 2

[0045] The difference from Embodiment 1 is that in this embodiment, the tubular pressure probe 3 is a hollow stainless steel tube with a length of 50 mm, an inner diameter of 0.5 mm, and an outer diameter of 0.6 mm; the tubular joint 4 is a threaded stainless steel tube, and its The inner diameter is 0.6 mm, and the length is 40 mm; one end of the tubular joint 4 is screwed onto the pressure sensor of the pressure measurement system 5 through threads, specifically connected to the detection end of the pressure sensor. The response frequency of the pressure measurement system 5 is 1 KHz, and the range is -5KPa, data acquisition frequency 100Hz.

[0046] The above-mentioned device is used for measurement and evaluation, and the process is as follows:

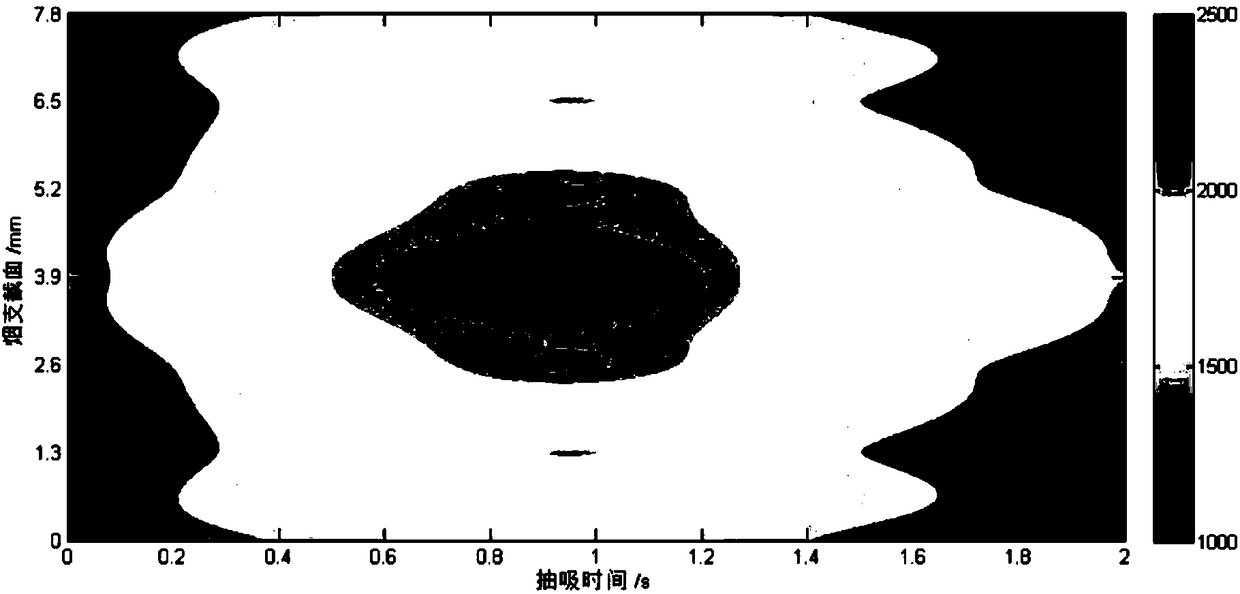

[0047] Select a certain brand of slim cigarette 2 for detection, first carry out air leakage inspection and suction capacity correction on the cigarette suction system 6 according to the conditions stipulated in the national stand...

Embodiment 3

[0049] The difference from Embodiment 1 is that in this embodiment, the tubular pressure probe 3 is a hollow glass tube with a length of 60 mm, an inner diameter of 0.7 mm, and an outer diameter of 0.8 mm; the tubular joint 4 is a hose with an inner diameter of 0.8 mm , the length is 60 mm; one end of the tubular joint 4 is set on the end of the tubular pressure probe 3, and the other end is set on the pressure sensor. The pressure measurement system 5 has a response frequency of 1KHz, a measuring range of -3KPa, and a data collection frequency of 100Hz.

[0050] The above-mentioned device is used for measurement and evaluation, and the process is as follows:

[0051] Select a certain brand of slim cigarette 2 for detection, first carry out air leakage inspection and suction capacity correction on the cigarette suction system 6 according to the conditions stipulated in the national standard GB / T16450-2004; smoke the cigarette 2 according to the set suction parameters, and dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com