Damping-adjustable magneto-rheological piezoelectric exhaust silencer

An exhaust muffler and variable piezoelectric technology, which is applied in the direction of electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, instruments, etc., can solve the problem that the exhaust muffler exhaust muffler effect is not ideal, and the absorption frequency band Narrow, low sound absorption coefficient, etc., to achieve the effect of simple structure, weakened noise, and strong sound absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

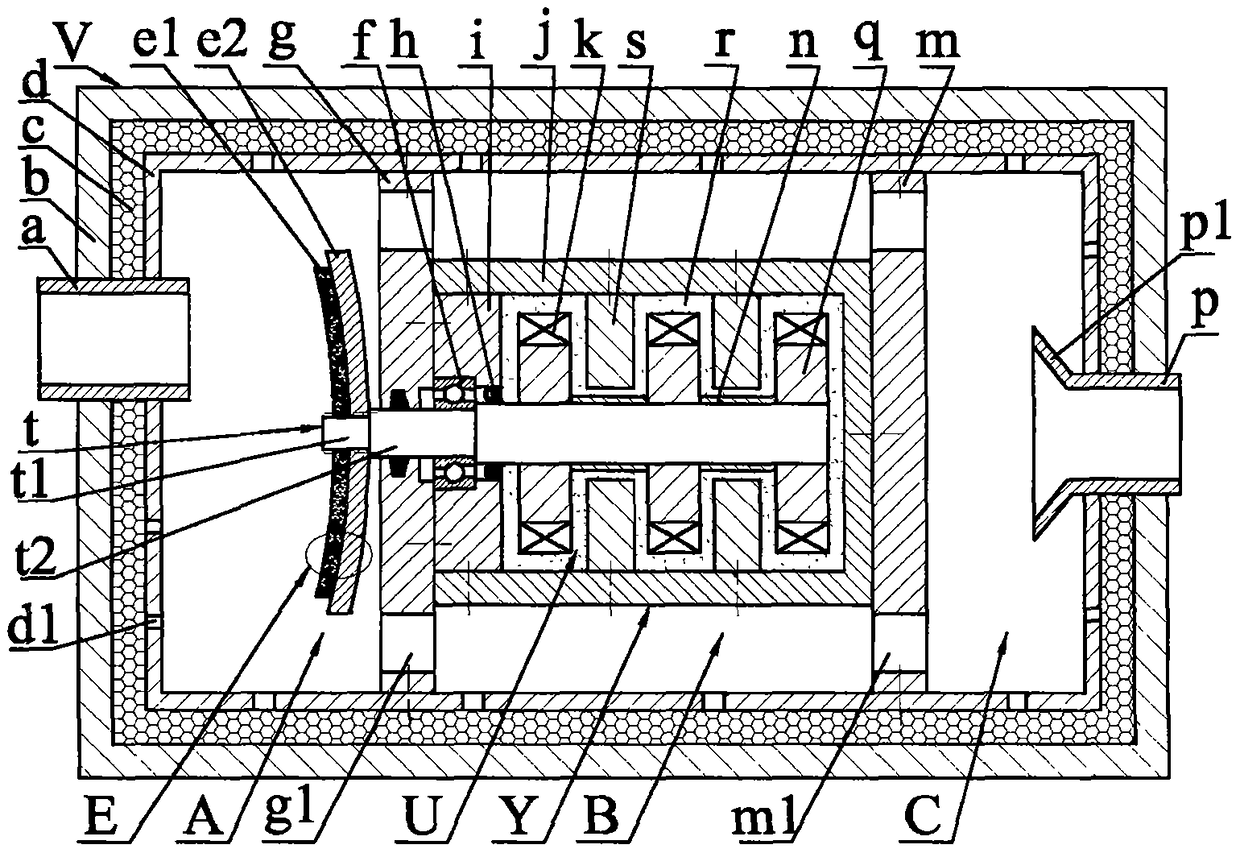

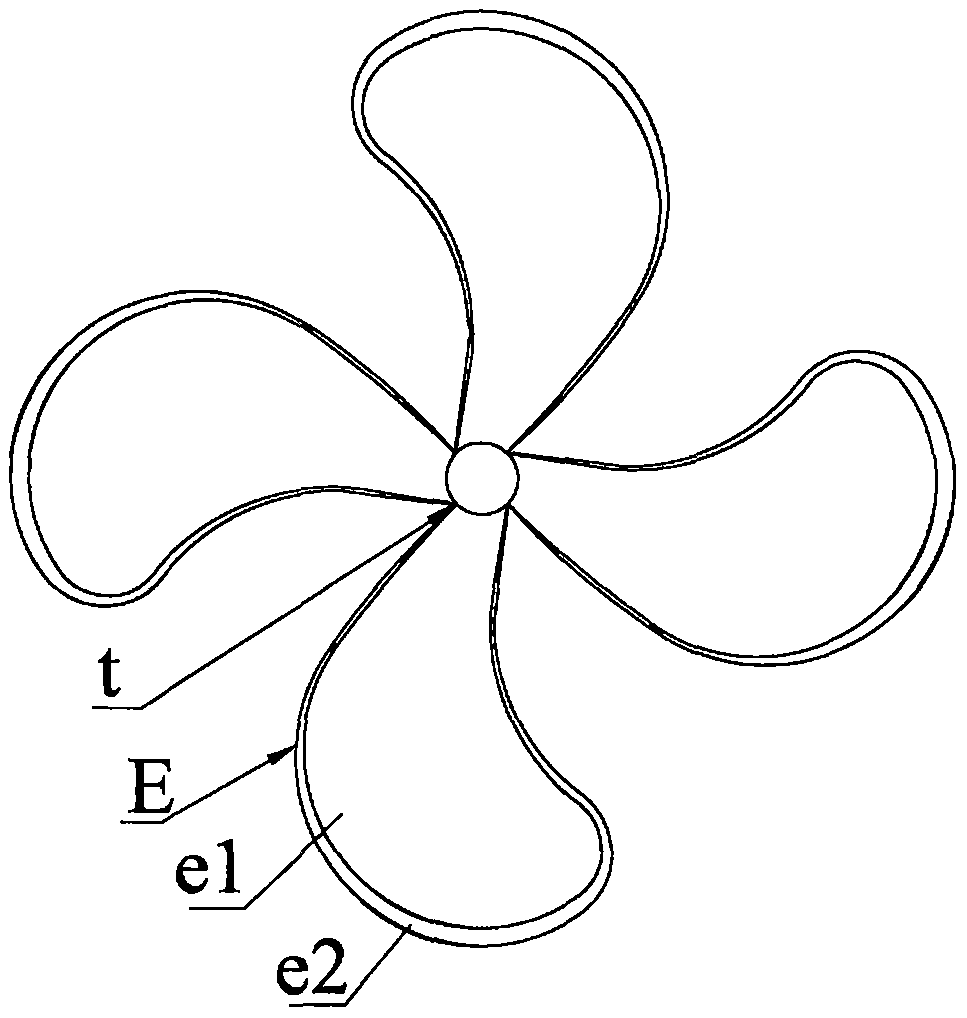

[0011] A magneto-rheological piezoelectric exhaust muffler with adjustable damping, comprising a hollow cylinder V, an air inlet pipe a is arranged along one end of the cylinder V deviated from the axis, and a left end is arranged along the axis of the other end of the cylinder V It is a conical p1 outlet pipe p; cylinder V includes shell b, glass wool c and perforated plate d, and there are a number of air holes d1 on perforated plate d; cylinder V is surrounded by left partition g and right partition m The cylinder V is divided into the first chamber A, the second chamber B and the third chamber C perpendicular to the axial direction of the cylinder V. The air inlet pipe a communicates with the first chamber A, and the air outlet pipe p communicates with the third chamber C. Connected; the left partition g and the right partition m are evenly distributed with left flow holes g1 and right flow holes m1, the sum of the sectional areas of the left flow holes g1 is greater than o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com