Shield tunnel segment backfill grouting construction method

A shield tunnel segment and wall grouting technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of excessive surface settlement, large filling coefficient, and low construction risk, and achieve improved compactness, The effect of low cost and low construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

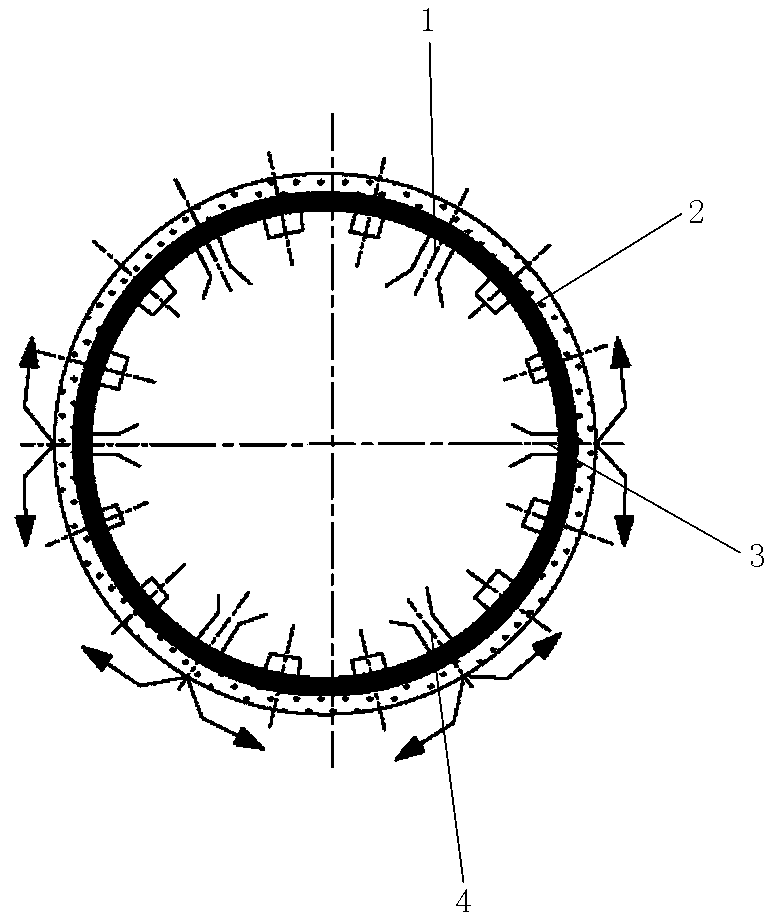

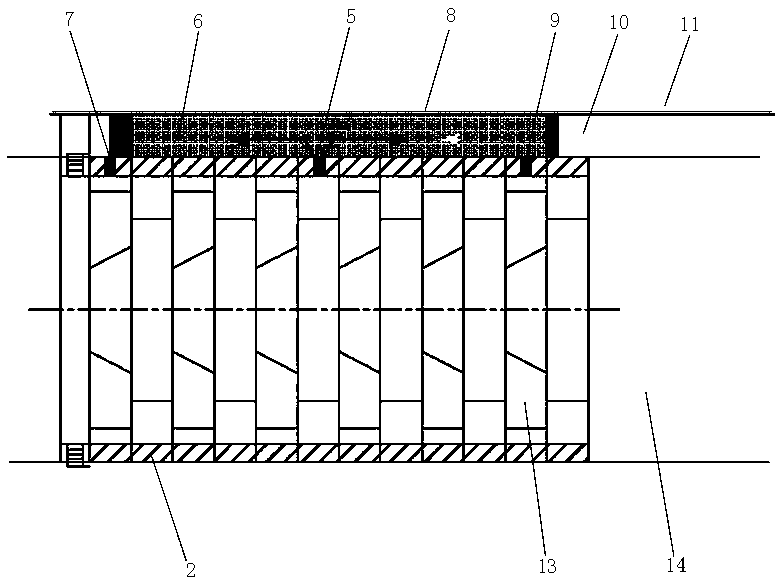

[0029] Embodiment 1: as figure 1 and figure 2 As shown, a post-grouting construction method for the segment wall of a shield tunnel comprises the following steps:

[0030] (1) In the construction tunnel 14, inject mortar below the middle part of the tunnel ring 2 formed by each segment 13 ( figure 1 , figure 2 The middle arrow indicates the flow direction of the mortar liquid), through the grouting pipes in the middle grouting hole 3 and the lower grouting hole 4 in the shield tail grouting hole, while the shield is advancing, the shield tail is formed by each segment Below the middle of the tunnel ring, press-inject mortar. Below the middle of the tunnel ring is the position below the horizontal diameter of the tunnel ring. Injecting mortar below the middle of the tunnel ring formed by the segments at the tail of the shield is to ensure that the gap space 10 between the segments below the middle and the tunnel soil layer 11 is filled densely, so as to prevent the segmen...

Embodiment 2

[0033] Embodiment 2: as figure 1 and figure 2 As shown, a post-grouting construction method for the segment wall of a shield tunnel comprises the following steps:

[0034] (1) Arrangement of the slurry-blocking net 8: a slurry-blocking net is provided between the segment and the tunnel soil layer. The grout blocking net is used to encapsulate the grout injected from the grouting hole reserved on the segment to ensure that the space between the segment and the tunnel soil is densely packed. The slurry-blocking net is made of iron, and the mesh diameter of the slurry-blocking net is smaller than or equal to the particle size of the sand in the mortar, encapsulating the injected slurry. The pulp blocking net is an iron net, or a net made of synthetic plastic, or a plastic cloth.

[0035] (2) Press-inject mortar into the grouting net below the middle part of the tunnel ring formed by each segment, and pass through the grouting pipe in the middle grouting hole 3 and the lower g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com