Forming method of arc-shaped box girder formwork

A forming method and box girder technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of on-site adjustment difficulties, delayed formwork removal time, cost increase, etc., to improve appearance quality and geometric dimension accuracy, avoid Floating and position offset, the effect of ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

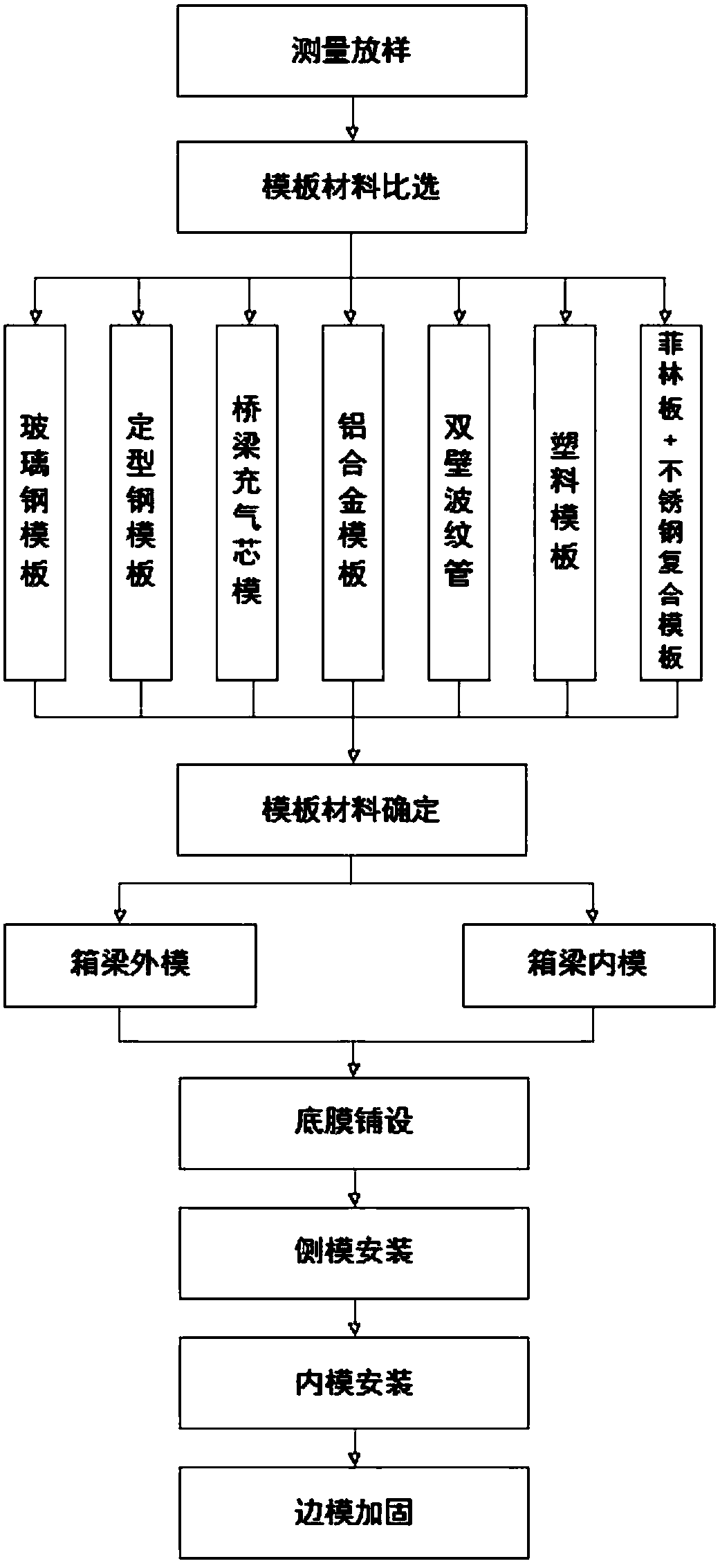

[0036] Such as figure 1 , the curved box girder formwork forming method of the present invention, comprises the following steps:

[0037] 1. Measurement and stakeout: Before the construction of the box girder, determine the key control pile number of the arc box girder in advance, and then determine the coordinates of the middle pile through the axis circle curve in the plan view of the arc box girder, and further calculate the base plate, the pile on the left side of the top plate and the The coordinates of the right pile. Finally, on-site lofting is carried out, and the span of a vertical horizontal bar is added on both sides of the roof. After calculation, the span of a longitudinal horizontal bar of the curved box girder is 600mm. Increase the stake out 800mm wide pedestrian passage. Sprinkle the marking line with white ash, then determine the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com