Continuous quenching device for jacking chain wheel workpiece

A technology of quenching device and hoisting chain, applied in the direction of quenching device, manufacturing tool, furnace, etc., can solve the problems of not being suitable for mass production, difficult to overcome batch quality problems, low efficiency of manual moving, etc., to avoid oxidation, ensure The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

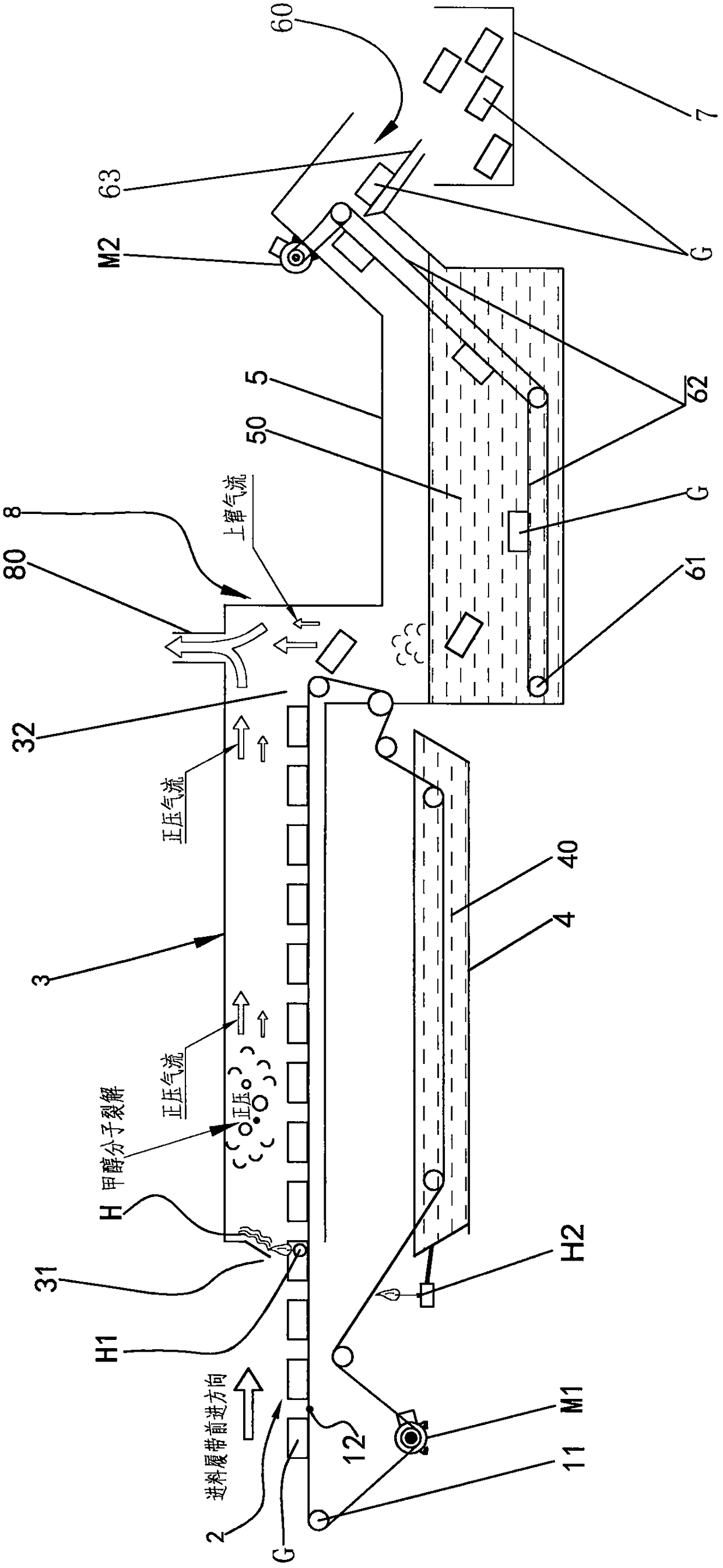

[0014] See figure 1 As shown, the continuous quenching device for the workpiece of the lifting sprocket includes a feeding motor M1, a feeding crawler 12, a feeding roller 11, a feeding area 2, a heating furnace area 3, a cooling tank 4, and a quenching medium The quenching tank 5 of 50, the discharge lifting part and the receiving frame 7, the feeding area 2 is located directly in front of the heating furnace area 3, and corresponds to the inlet side 31 of the heating furnace area 3, and the feeding motor M1 is located in the feeding area 2 Below, the quenching tank 5 is adjacent to the outlet side 32 of the heating furnace area 3, and the feeding motor M1 drives the feeding crawler 12 to advance continuously through the driving feed transmission part, so that the feeding crawler 12 circulates through the feeding area 2 and the heating furnace area 3. The cooling tank 4, the feed roller 11 rotates with the feed crawler 12; the discharge lifting part is arranged in the quenchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com