Pigment solution for black matrix, black matrix and preparation method thereof, display panel

A technology of black matrix and pigment liquid, applied in pigment paste, photosensitive materials for opto-mechanical equipment, etc., can solve the problems of low resistance, high cost, low shading density, etc., and achieve high resistance, low cost, and access capability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

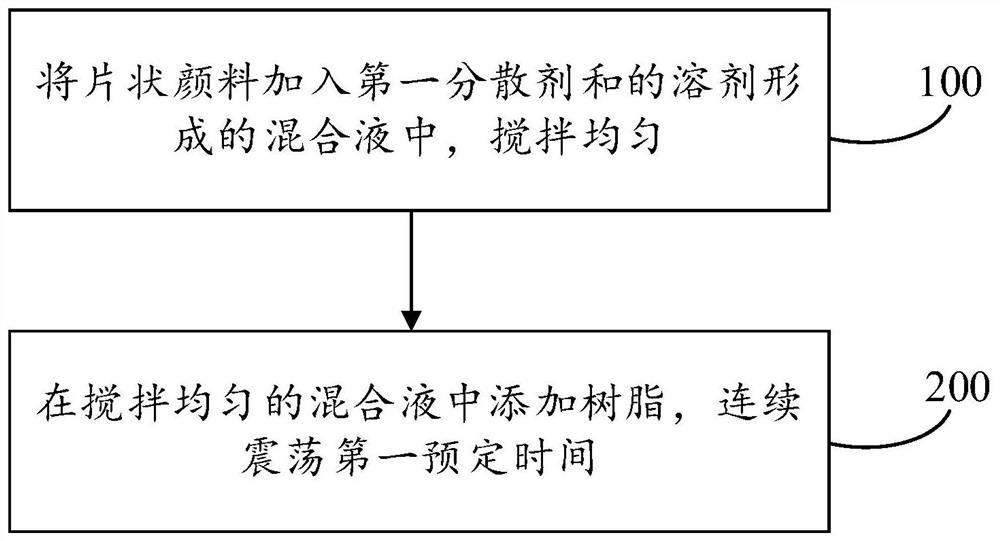

[0035] The present invention also provides a method of preparing a pigment liquid for a black matrix of the above embodiment, with reference image 3 As shown, including the following steps:

[0036] Step 100, add the sheet-like pigment to the mixture formed by the first dispersing agent and the solvent, stir well.

[0037] Step 200, add a resin in a mixed mixture that is stirred, and continuously oscillating the first predetermined time.

[0038] During the preparation of the above-mentioned black matrix pigment liquid, the mass parts of the added components are specific to: 15 to 35 partial pigments, 1 to 5 parts of resin, 1 to 3 parts of the first dispersant, 60 ~ 85 parts of solvent. .

[0039] The first predetermined time may be from 4 h to 7 h, and the mixing process can be oscillated in the oscillator and / or mixed in a sand mill.

[0040] The present invention also provides a method of preparing a black matrix, a black matrix pigment liquid with a black matrix of the above...

Embodiment 1

[0046] Pigment liquid prepares:

[0047] Add 15 to 25 pieces of titanium dioxide (length, width of 150 nm, thickness of 20 nm) to 1 to 3 copies of BYK dispersing agent and 60 to 85 parts of PMA (propylene glycol methyl etheric acid) in a shake bottle containing zirconum In the mixture, stirring uniform conditions, add 1 to 5 parts of 611 resin;

[0048] The pigment liquid containing a sheet-like pigment was continuously oscillated.

[0049] Black matrix preparation:

[0050] The above pigment liquid is uniform with soluble resin, monomer, initiator, and graft or the like;

[0051] Coating, exposure, making black matrices after developing.

[0052] Tested, the thickness of the black matrix was 0.75 μm, the OD value was 4.3, and the volume resistance was 3.2 × 10. 6 Ω · cm.

Embodiment 2

[0054] Pigment liquid prepares:

[0055] Adding from 20 to 30 parts of titanium dioxide (length, width of 150 nm, thickness of 20 nm), 1 to 3 copies of BYK dispersing agent and 60 ~ 85 parts of PMA (propylene glycol methyl etheric acid) In the mixture, stirring uniform conditions, add 1 to 5 parts of 611 resin;

[0056] The pigment liquid containing a sheet-like pigment was continuously oscillated.

[0057] Black matrix preparation:

[0058] The above pigment liquid is uniform with soluble resin, monomer, initiator, and graft or the like;

[0059] Coating, exposure, making black matrices after developing.

[0060] Test, the thickness of the black matrix is 0.8 μm, the OD value is 4.8, and the volume resistance is 2.5 × 10 6 Ω · cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com