Composite white pigment, photoresist material containing same and application of composite white pigment

一种白色颜料、光阻材料的技术,应用在光阻材料,复合白色颜料领域,能够解决影响产品功能、断线、白色光阻遮蔽能力差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The specific preparation steps are mastered by those skilled in the art, such as mechanically opening and separating the non-white pigment particle clusters into isolated primary particles of a specific size, so that the entire surface of each particle can be contacted, and then the above-mentioned pigment particles Put it in the white liquid pigment, make its surface covered by the white pigment, and then dry to form composite pigment particles, and then go through the conventional pigment grinding and dispersion process to obtain the composite white pigment of the present invention.

[0032] Preferably, the photoresist material includes the following components in parts by weight: 5-15 parts of photosensitizer, 5-15 parts of dispersant, 50-80 parts of solvent, and 5-15 parts of composite white pigment.

[0033] More preferably, the photoresist material includes the following components in parts by weight: 8-12 parts of photosensitizer, 8-12 parts of dispersant, 60-70 p...

Embodiment 1

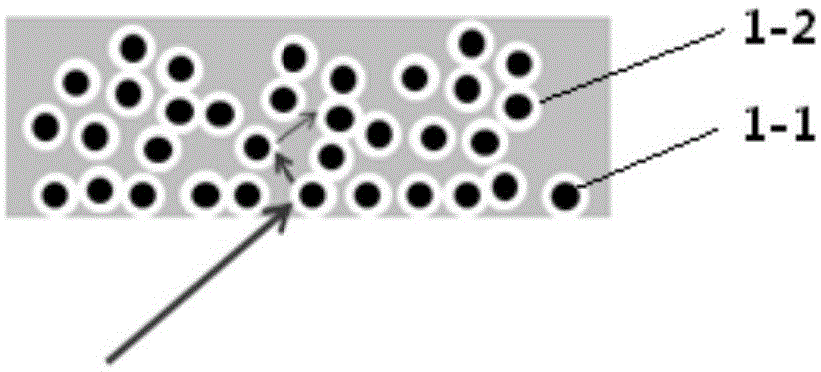

[0047] This embodiment provides a composite white pigment (round shape), which includes an inner core 1-1 made of black pigment, and an outer layer 1-2 made of white pigment covering the inner core 1-1.

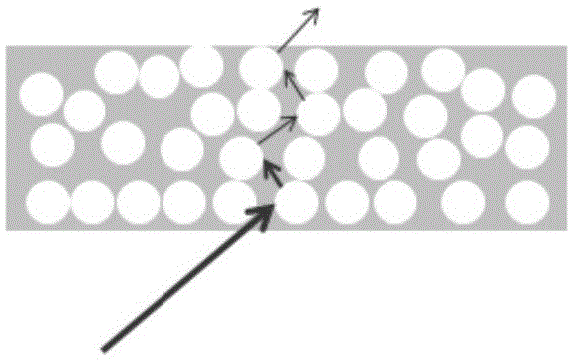

[0048] Such as figure 2 As shown, after the composite white pigment obtained in this embodiment is used in a photoresist material, the absorption rate of light can be significantly improved and the transmittance of light can be reduced due to the use of a specific composite white pigment. and figure 1 By comparison, it can be seen that part of the light passing through the specific white pigment is absorbed by the wrapped black pigment, and part of it is reflected. After multiple paths, only a small part of the light can pass through the surface, which greatly improves the material's light sensitivity. Covering.

Embodiment 2

[0050] This embodiment provides a composite white material. Compared with Embodiment 1, the only difference is that in this embodiment, the particle size of the inner core 1-1 is 0.08 μm, and the thickness of the outer layer 1-2 is 0.02 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com