Wood-plastic composite material for ornamental bamboo cultivation device and preparation method thereof

A technology of wood-plastic composite materials and cultivation devices, applied in the field of bamboo cultivation, can solve problems such as complex procedures, easy reintroduction of nutrient substrates into germs, and affecting the growth of bamboo roots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

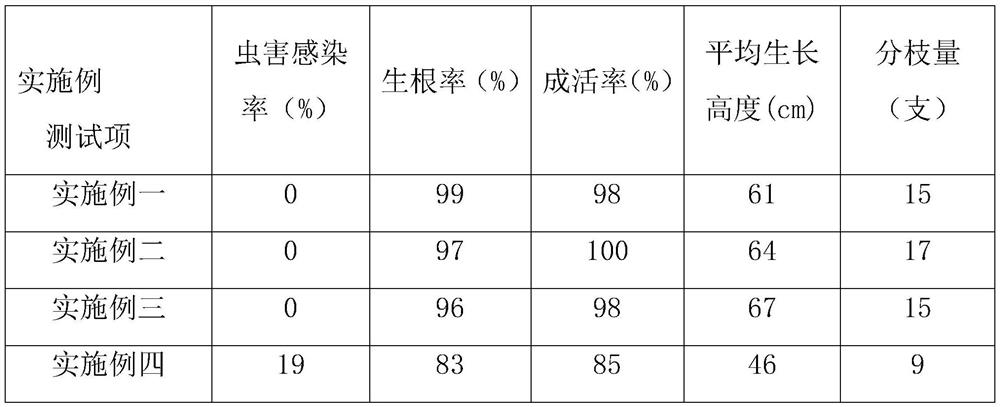

Embodiment 1

[0029] Wood-plastic composite materials for ornamental bamboo cultivation devices, including the following raw materials in parts by weight: 30 parts of straw powder, 40 parts of polypropylene granules, 2 parts of PE wax, 0.5 parts of leveling agent, 0.3 parts of defoaming agent, Malay 5 parts of acid anhydride grafted polyethylene, 1 part of silane coupling agent, 0.1 part of antioxidant, 8 parts of Ag-loaded sepiolite powder, 2 parts of sodium hexametaphosphate, 1 part of cetyltrimethylammonium bromide, Chitosan 6 parts. The preparation method of the wood-plastic composite material that this embodiment is used for ornamental bamboo cultivating device is as follows:

[0030] Step 1: Dissolve sodium hexametaphosphate in 10 times the volume of deionized water, then add Ag-loaded sepiolite powder, disperse for 45 minutes with ultrasonic waves with a frequency of 32KHz, and disperse at a speed of 45r / s, then add hexadecyltri Methyl ammonium bromide, fully reacted at 80°C under c...

Embodiment 2

[0038] Wood-plastic composite materials for ornamental bamboo cultivation devices, including the following raw materials in parts by weight: 45 parts of straw powder, 50 parts of polypropylene granules, 4 parts of PE wax, 1.0 parts of leveling agent, 0.8 parts of defoaming agent, Malay 6 parts of acid anhydride grafted polyethylene, 3 parts of silane coupling agent, 0.3 parts of antioxidant, 10 parts of Ag-loaded sepiolite powder, 3 parts of sodium hexametaphosphate, 2 parts of cetyltrimethylammonium bromide, Chitosan 8 parts. The preparation method of the wood-plastic composite material that this embodiment is used for ornamental bamboo cultivating device is as follows:

[0039] Step 1: Dissolve sodium hexametaphosphate in 10 times the volume of deionized water, then add Ag-loaded sepiolite powder, disperse for 45 minutes with ultrasonic waves with a frequency of 32KHz, and disperse at a speed of 45r / s, then add hexadecyltri Methyl ammonium bromide, fully reacted at 80°C und...

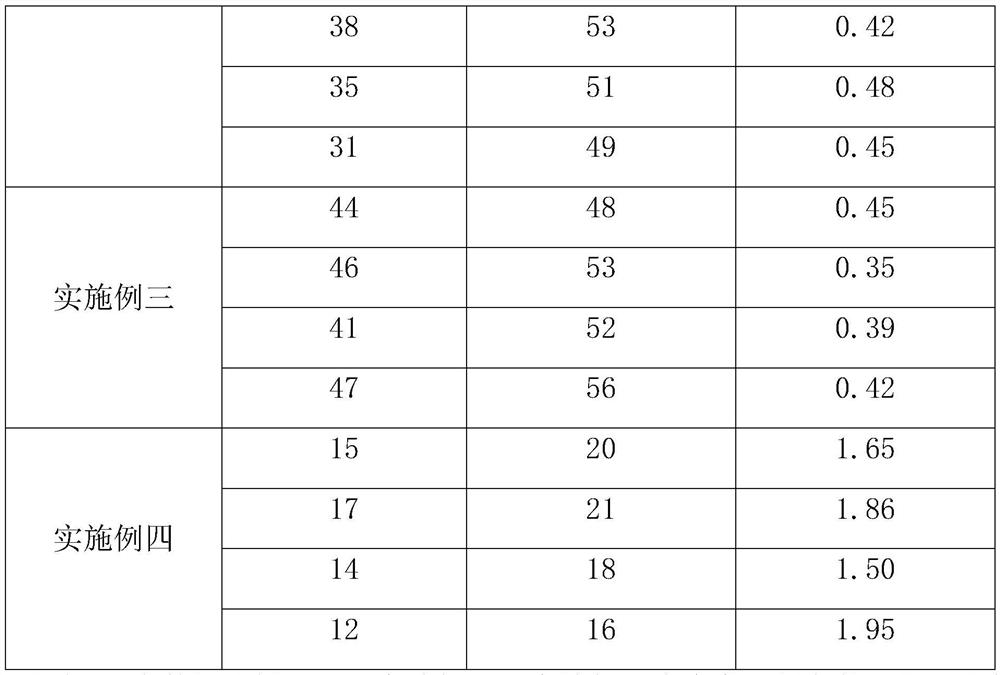

Embodiment 3

[0047] Wood-plastic composite materials for ornamental bamboo cultivation devices, including the following raw materials in parts by weight: 40 parts of straw powder, 45 parts of polypropylene granules, 3 parts of PE wax, 0.7 parts of leveling agent, 0.6 parts of defoaming agent, Malay 5.5 parts of anhydride grafted polyethylene, 2 parts of silane coupling agent, 0.2 part of antioxidant, 9 parts of Ag-loaded sepiolite powder, 2.5 parts of sodium hexametaphosphate, 1.5 parts of cetyltrimethylammonium bromide, Chitosan 7 parts. The preparation method of the wood-plastic composite material that this embodiment is used for ornamental bamboo cultivating device is as follows:

[0048] Step 1: Dissolve sodium hexametaphosphate in 10 times the volume of deionized water, then add Ag-loaded sepiolite powder, disperse for 45 minutes with ultrasonic waves with a frequency of 32KHz, and disperse at a speed of 45r / s, then add hexadecyltri Methyl ammonium bromide, fully reacted at 80°C unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com