Energy-saving environment-friendly lime kiln for smoke gas afterheat reuse

An energy-saving and environment-friendly lime kiln technology, which is applied in the field of energy-saving and environment-friendly lime kiln for waste heat recovery of flue gas, can solve the problem of waste heat not being utilized, achieve obvious energy-saving effect and increase furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

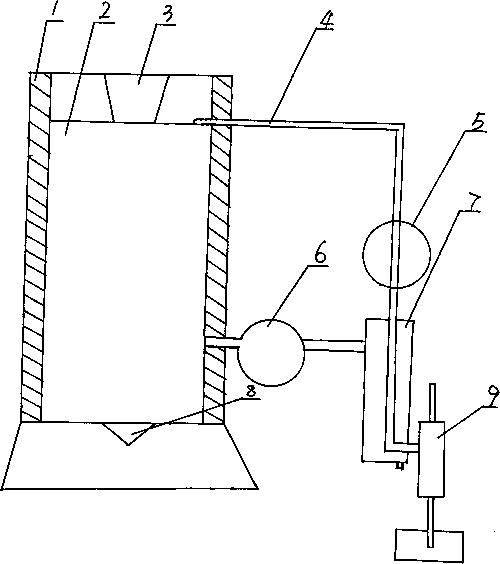

[0007] According to the accompanying drawings, the present invention includes a furnace body 1 provided with an insulating layer. The furnace body is provided with a furnace 2, the top of the furnace is provided with an automatic feeding port 3, the lower end is provided with an automatic ash discharge port 8, and the top of the furnace is provided with a ring-shaped smoke outlet. Road 4, the flue outlet communicates with the desulfurization and dust collector 9 through the fan 5 through the heat exchanger 7, the heat exchanger is provided with an air inlet and outlet, and the air outlet communicates with the air inlet at the lower part of the furnace through the fan 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com