An energy-saving and environment-friendly lime kiln for flue gas reuse

An energy-saving and environment-friendly lime kiln technology, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of waste and waste heat of high-temperature flue gas not being used, and achieve the effect of increasing furnace temperature and obvious energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

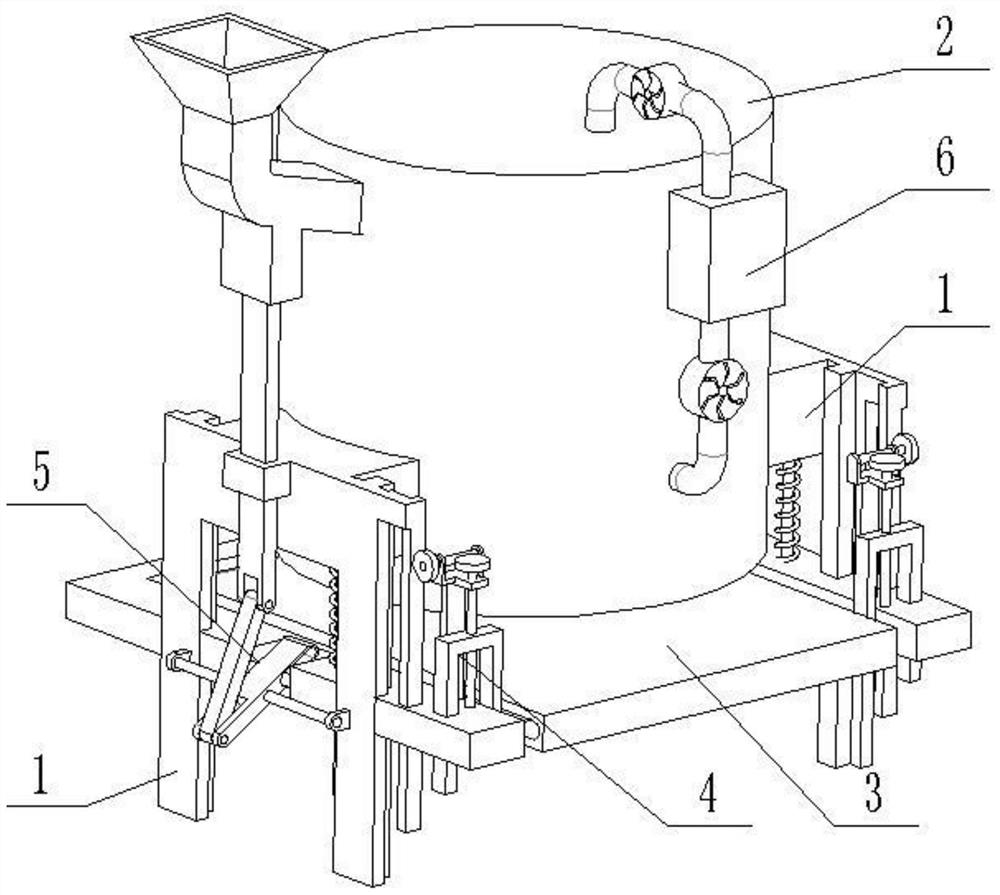

[0025] Combine below Figure 1-8 Describe this embodiment, an energy-saving and environment-friendly lime kiln for flue gas reuse, including a support 1, a kiln 2, an ash receiving seat 3, an ash unloading control part 4, a feed control part 5 and a flue gas circulation control processing part 6, There are two supports 1, the kiln 2 is connected between the two supports 1, the ash receiving seat 3 is slidably connected on the two supports 1, the ash receiving seat 3 is located directly below the kiln 2, and the two unloading seats The ash control parts 4 are symmetrically arranged at both ends of the ash receiving seat 3, and there are two ash discharge control parts 4, and the two ash discharge control parts 4 are respectively connected with the two brackets 1, and the feed control part 5 is set on one of the brackets 1, the left end of the ash receiving seat 3 is connected to the feeding control part 5, and the upper end of the feeding control part 5 is connected to the kiln...

specific Embodiment approach 2

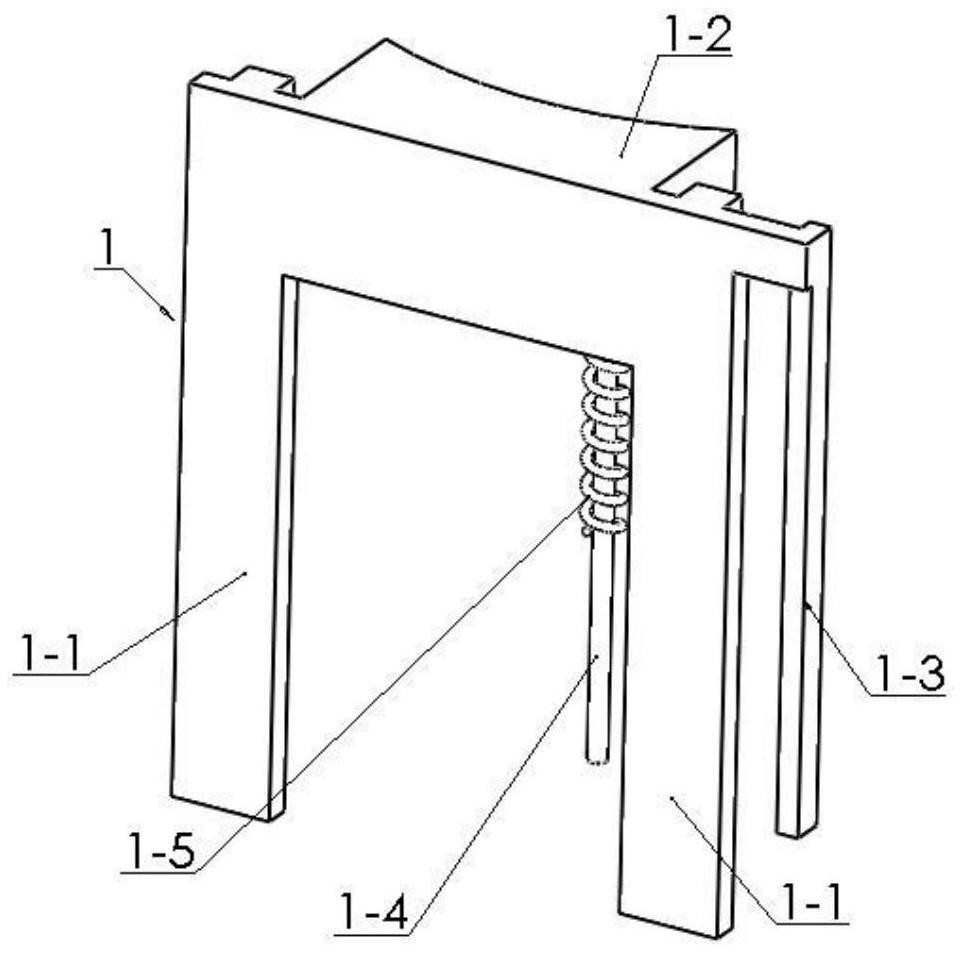

[0027] Combine below Figure 1-8 To illustrate this embodiment, the bracket 1 includes a T-shaped riser 1-1, a connecting seat 1-2, a rack 1-3, a spring sleeve rod 1-4 and a spring 1-5, and the connecting seat 1-2 is fixedly connected On the upper ends of the two T-shaped vertical plates 1-1, the rack 1-3 is fixedly connected to the T-shaped vertical plate 1-1 at the front end, and the lower end of the connecting seat 1-2 is fixedly connected with a spring sleeve rod 1-4, and the spring Spring 1-5 is sleeved on sleeve bar 1-4.

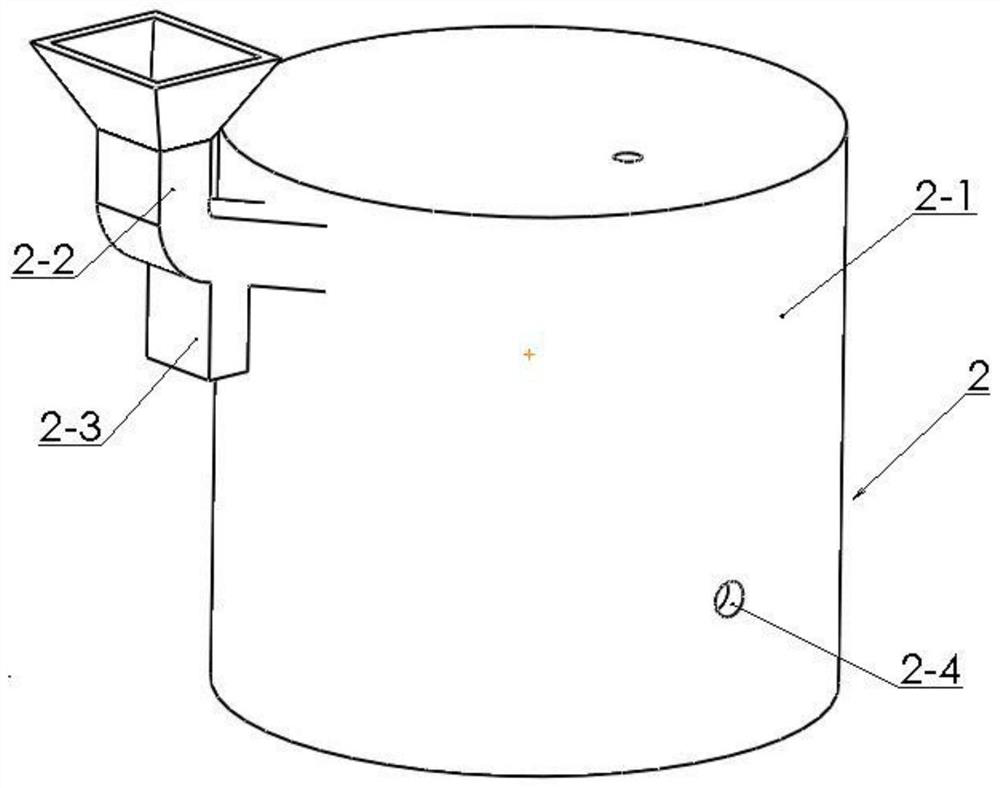

[0028] The kiln 2 includes a furnace body 2-1, a feed pipe 2-2, a baffle slide 2-3, an air inlet 2-4 and an ash filter plate 2-5 with a plurality of sieve holes. The lower end of 2-1 is hollowed out, the furnace body 2-1 is fixedly connected between the two connection seats 1-2, the upper end of the furnace body 2-1 is connected and communicated with the feed pipe 2-2, and the lower end of the feed pipe 2-2 Connect and communicate with the baffle sli...

specific Embodiment approach 3

[0032] Combine below Figure 1-8 To illustrate this embodiment, the feed control member 5 includes a rod frame 5-1, a shaft rod 5-2, a rotating rod 5-3, a cylindrical rod chute 5-4, a cylindrical rod 5-5, and a connecting rod 5- 6. The reciprocating baffle plate 5-7 and the fixed sliding sleeve 5-8, the shaft rod 5-2 are fixedly connected between the two rod frames 5-1, and the two rod frames 5-1 are fixedly connected to the two T-shaped On the vertical plate 1-1, the middle end of the rotating rod 5-3 is rotatably connected to the shaft rod 5-2, and one end of the rotating rod 5-3 is provided with a cylindrical rod chute 5-4, and the cylindrical rod 5-5 is slidably connected to the In the cylindrical rod chute 5-4, the two ends of the cylindrical rod 5-5 are respectively fixedly connected to the two ends of the cylindrical rod placement groove 3-3, and the other end of the rotating rod 5-3 is connected with the connecting rod 5-3 through the hinge shaft. 6. The upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com