Hydraulic lifting-type building rebar equidistant automatic cutting device

An automatic cutting device and a technology for building steel bars, which are applied in the field of cutting devices, can solve the problems of reducing the work efficiency of users, causing injuries to users, and increasing the danger of users, so as to achieve improved safety, strong practicability, and reduced accidental injury operations Personnel Risk Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

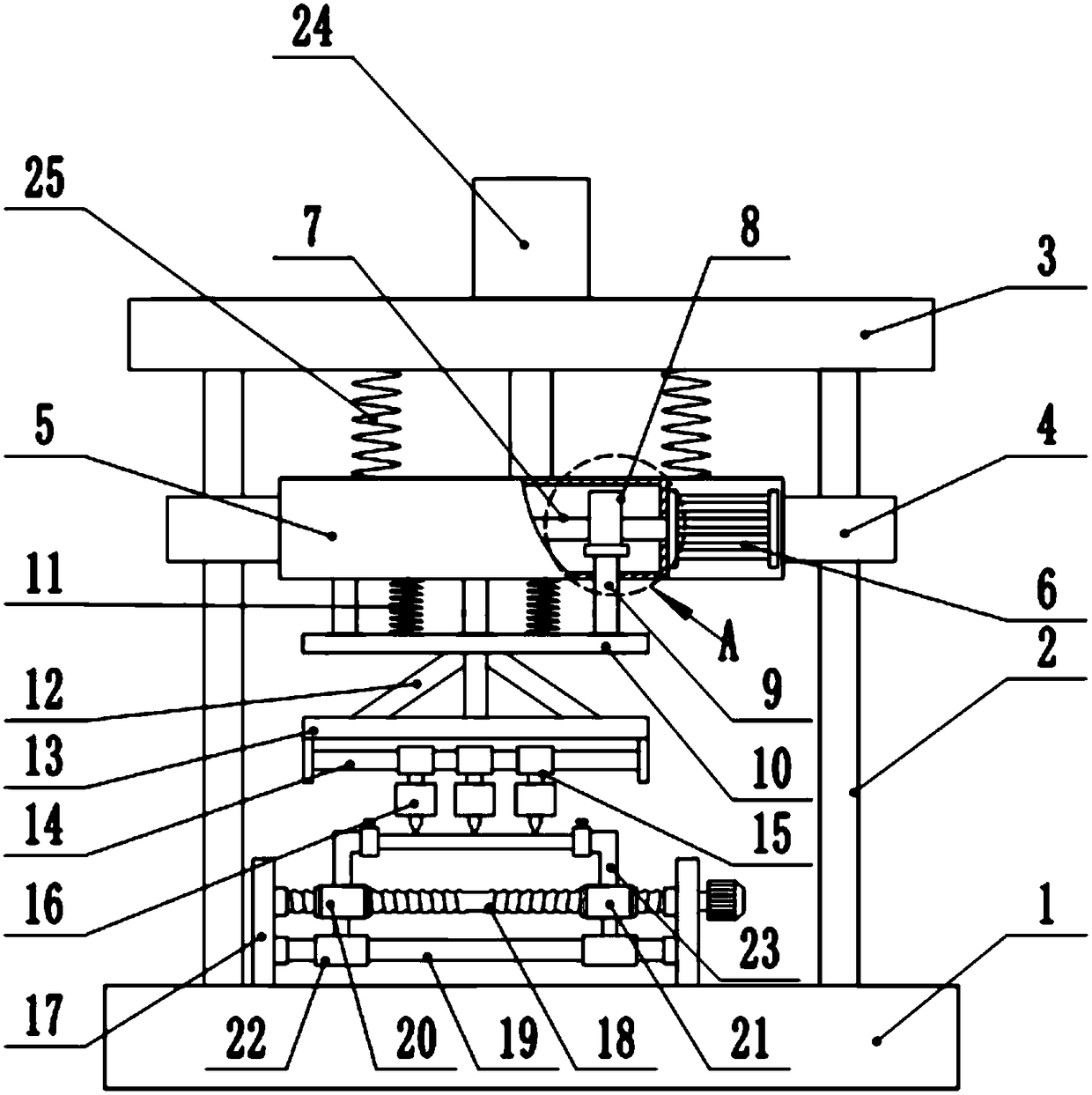

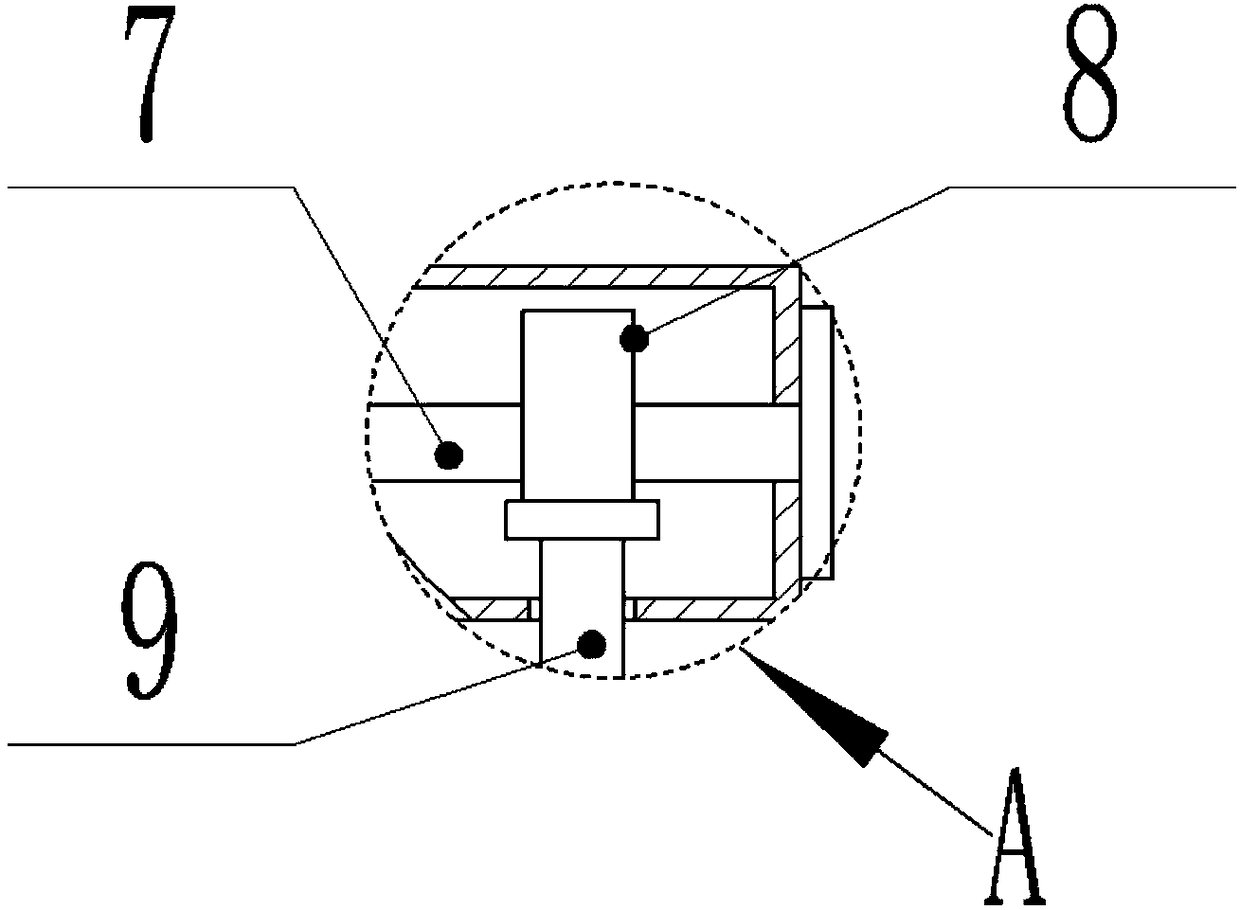

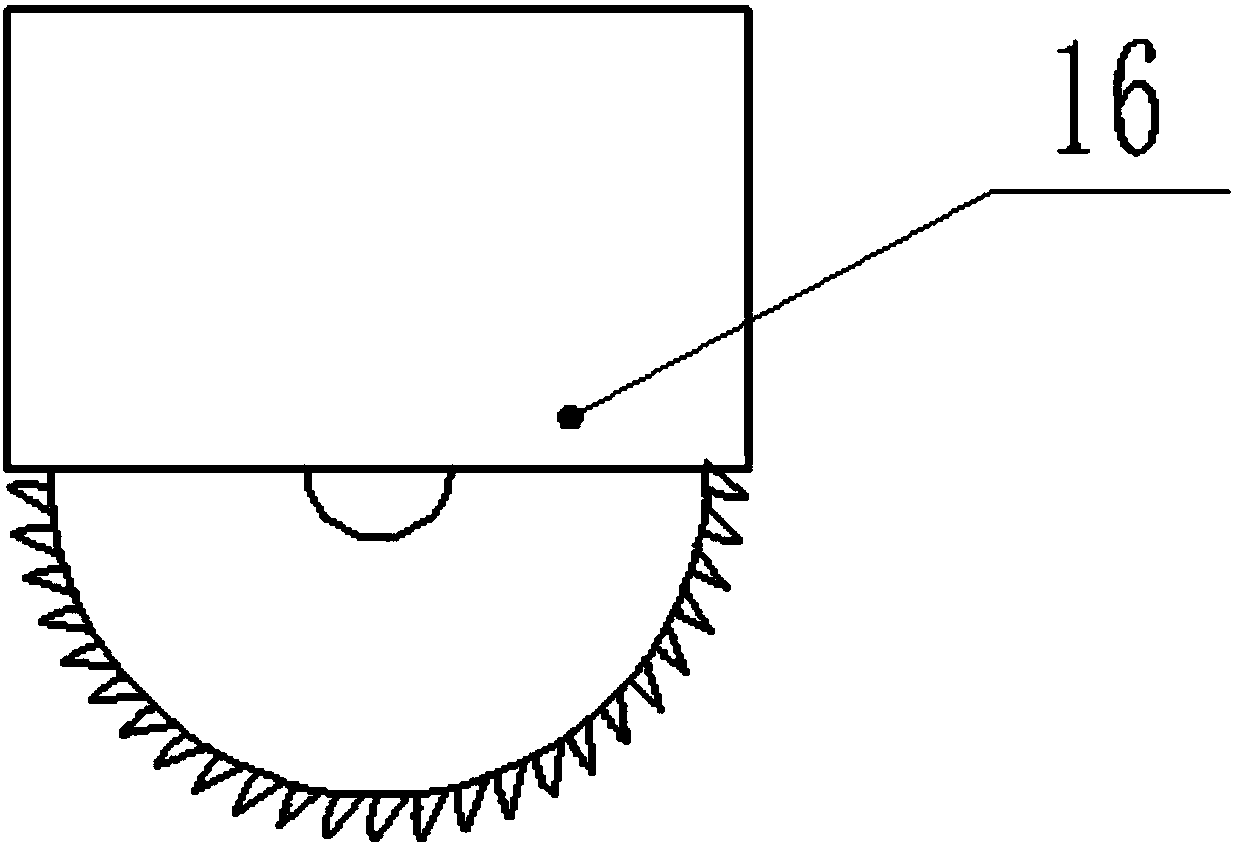

[0020] see Figure 1-3 , a hydraulic lifting type construction steel bar isometric automatic cutting device, comprising a base 1, a device box 5, a cutting machine 16, a ball screw 18, a left screw sleeve 20 and a right screw sleeve 21, the left and right sides of the upper surface of the base 1 There are supporting sliding columns 2 symmetrically, and the supporting sliding columns 2 and the base 1 are connected by welding. The upper side of the supporting sliding columns 2 is also fixedly connected with a horizontal plate 3, which slides on the supporting sliding columns 2 on the left and right sides. A guide mounting ear 4 is installed, and a device box 5 is fixedly connected with a screw between the guide mounting ears 4 on the left and right sides. The inside of the device box 5 is a hollow structure and the inside right side of the device box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com