Laser intelligent agricultural machine

An agricultural machine and intelligent technology, applied in the field of laser intelligent agricultural machine, can solve the problems of waste of field area, planting area, and high equipment input cost, and achieve the effect of saving construction cost, reducing floor space and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

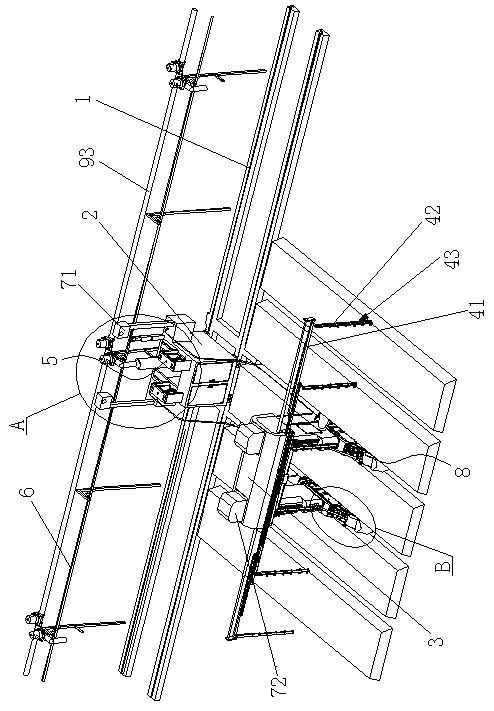

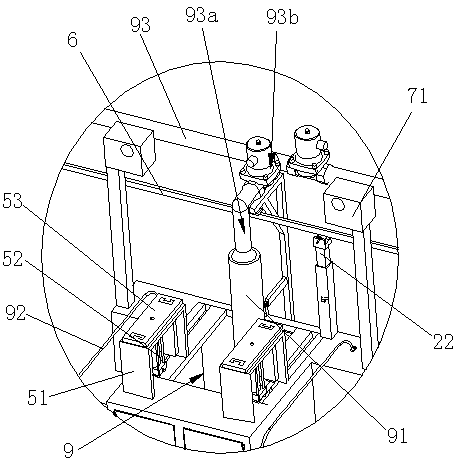

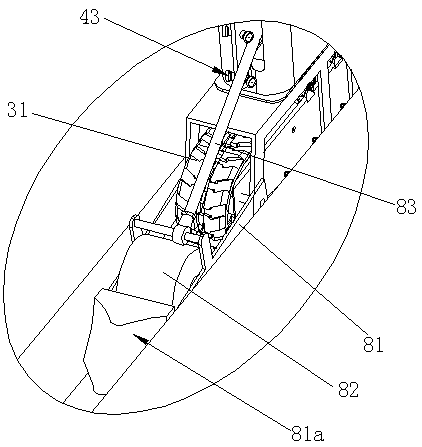

[0032] Such as Figure 1 to Figure 12 Shown is the structural representation of the present invention,

[0033] Wherein the reference numerals are: cross rail 1, rail 11, traverse vehicle 2, wheel 21, groove 21a, pole 22, straight agricultural machine 3, crawler belt 31, extension rod 41, nozzle support 42, Spray head 43, sprinkler telescopic bracket 44, sprinkler head 45, jacking mechanism 5, mounting bracket 51, hydraulic jacking cylinder 52, jacking plate 53, power pole 6, laser emitting and receiving device 71, laser reflecting device 72 , outer frame 72a, reflecting plate 72b, reclamation mechanism 8, reclamation frame 81, tapered portion 81a, pressure wheel 82, connecting rod 83, supply box 9, supply pipe 91, connection pipe 92, liquid supply pipe 93, liquid supply port 93a, solenoid valve 93b.

[0034] Such as Figure 1 to Figure 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com