Intelligent testing and evaluating method for properties of flowing waste soil in tunneling soil cabin and device

A technology of flowing slag and shield soil, which is applied in the fields of shield intelligent equipment and slag property evaluation devices, can solve problems such as inability to test slag, achieve the effect of reducing the service life of shield machines and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

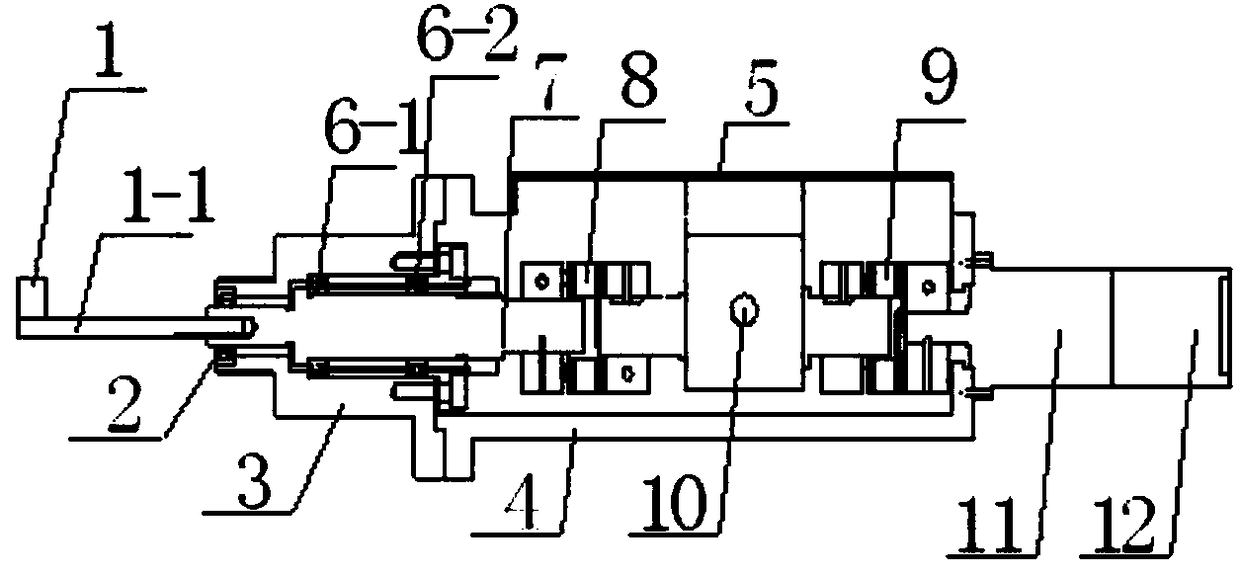

[0033] The present invention will be further described below in conjunction with the embodiments shown in the drawings.

[0034] The intelligent evaluation method for the properties of the flowing muck in the shield soil bin of the present invention is to interact with the moving muck through a horizontally rotating shear plate and measure the relevant torque value. The components of the tested torque value include: (1) shear The shear torque of the cutting board head and the muck at the edge of the board; (2) the extrusion torque of the cutting board head and the surrounding muck; (3) the shear torque between the outer edge of the shear board shaft and the muck, where If the shear strength of the moving muck is small (the shear strength of the moving muck is small in an ideal state), the tested torque contribution is mainly (2). Based on this, the present invention believes in the concept whether the muck is For an ideal state, there are two requirements, namely: whether the nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com