Experiment device for excess pressure energy recycling and compressed air energy storage

A technology for compressed air energy storage and energy recovery, which is used in measurement devices, testing of machinery/structural components, instruments, etc. It can solve the problems of huge initial investment, long construction period, and difficulty in recovering energy, and achieve energy recovery efficiency. High, wide range of applications, flexible functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

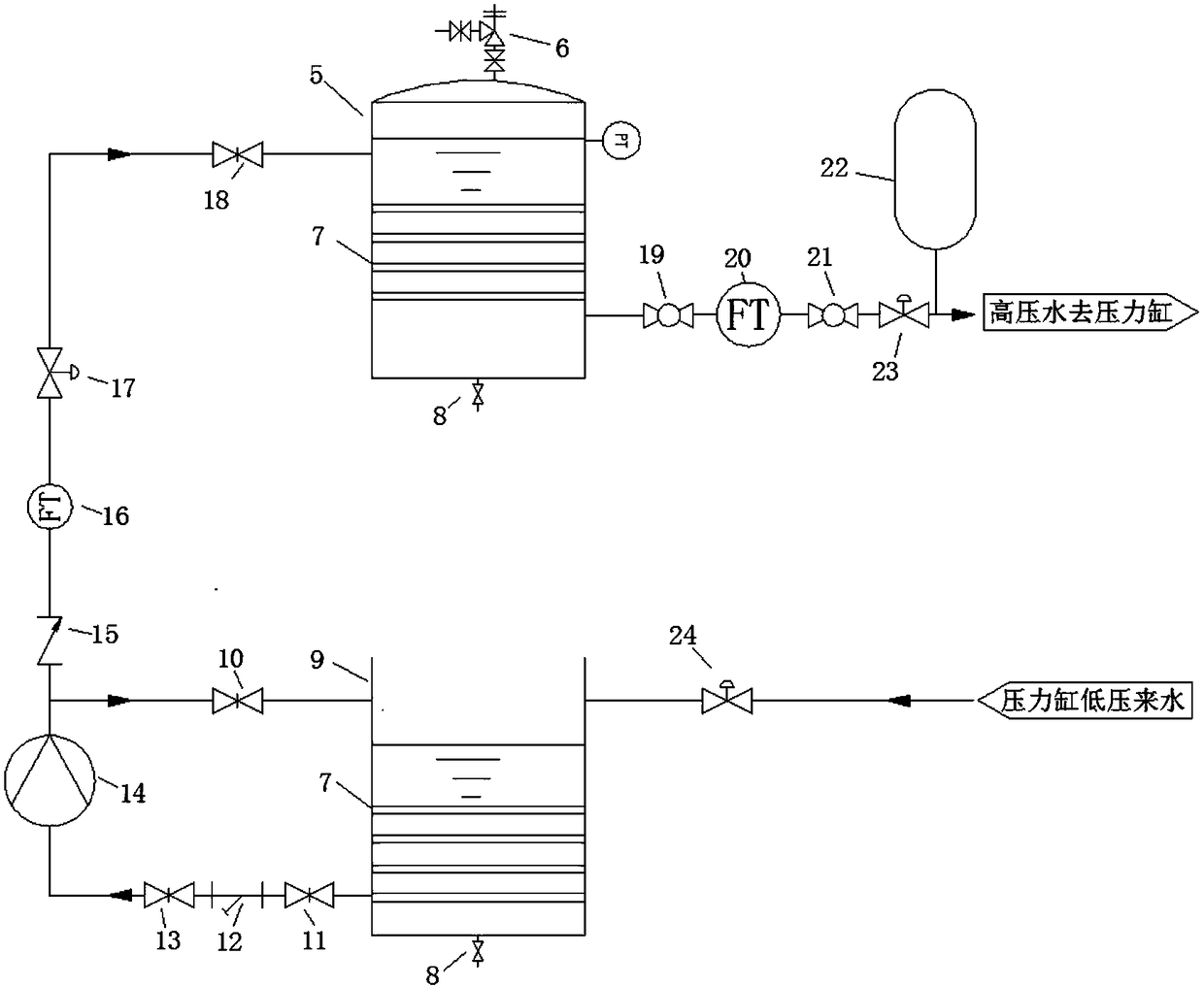

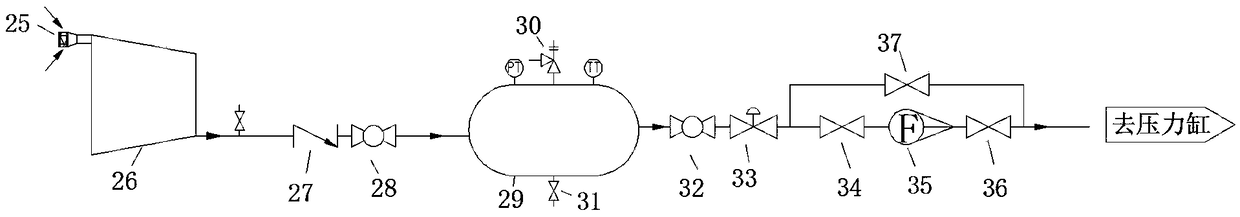

[0021] see figure 1 , the present invention structurally includes a residual pressure energy simulation module 1, a gas supply module 2, an energy replacement module 3 and an energy storage and release module 4, and the residual pressure energy simulation module 1 and the energy storage and release module 4 are respectively connected to the energy replacement module 3 ends.

[0022] see figure 2 , the residual pressure energy simulation module 2 of the present invention is provided with a high-pressure water tank 5, a safety valve 6, a steady flow grid 7, a drain valve 8, a low-pressure water tank 9, a first gate valve 10, a second gate valve 11, and a Y-type filter 12. Third gate valve 13, high pressure pump 14, first check valve 15, first flow meter 16, first regulating valve 17, fourth gate valve 18, first ball valve 19, second flow meter 20, second bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com