Noise piezoelectric power generation self-powered magneto-rheological muffler used for motorbikes

A technology for piezoelectric power generation and self-supply energy, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, noise reduction devices, generators/motors, etc. The noise reduction effect is not ideal enough to achieve the effect of sound absorption frequency bandwidth and sound power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

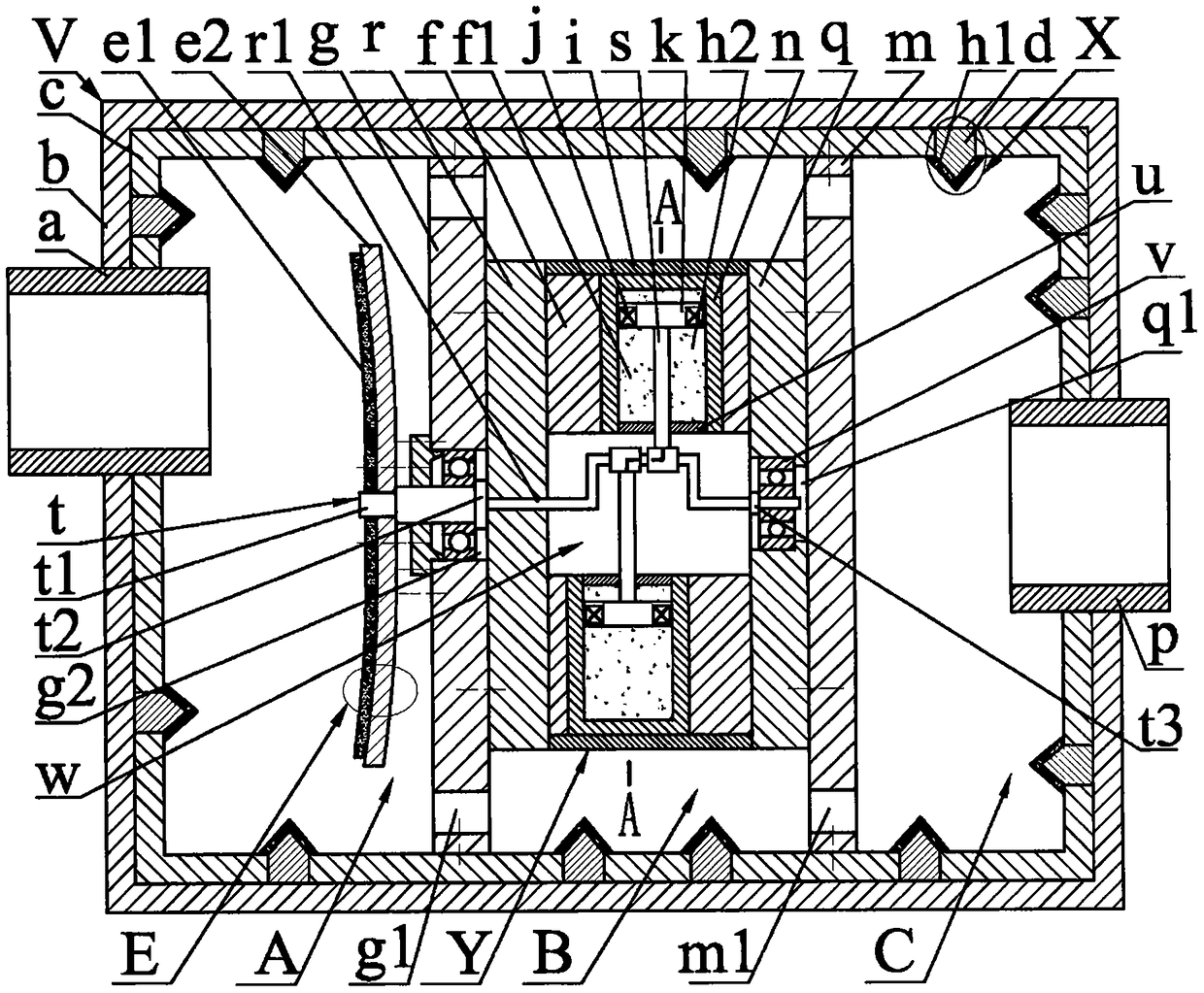

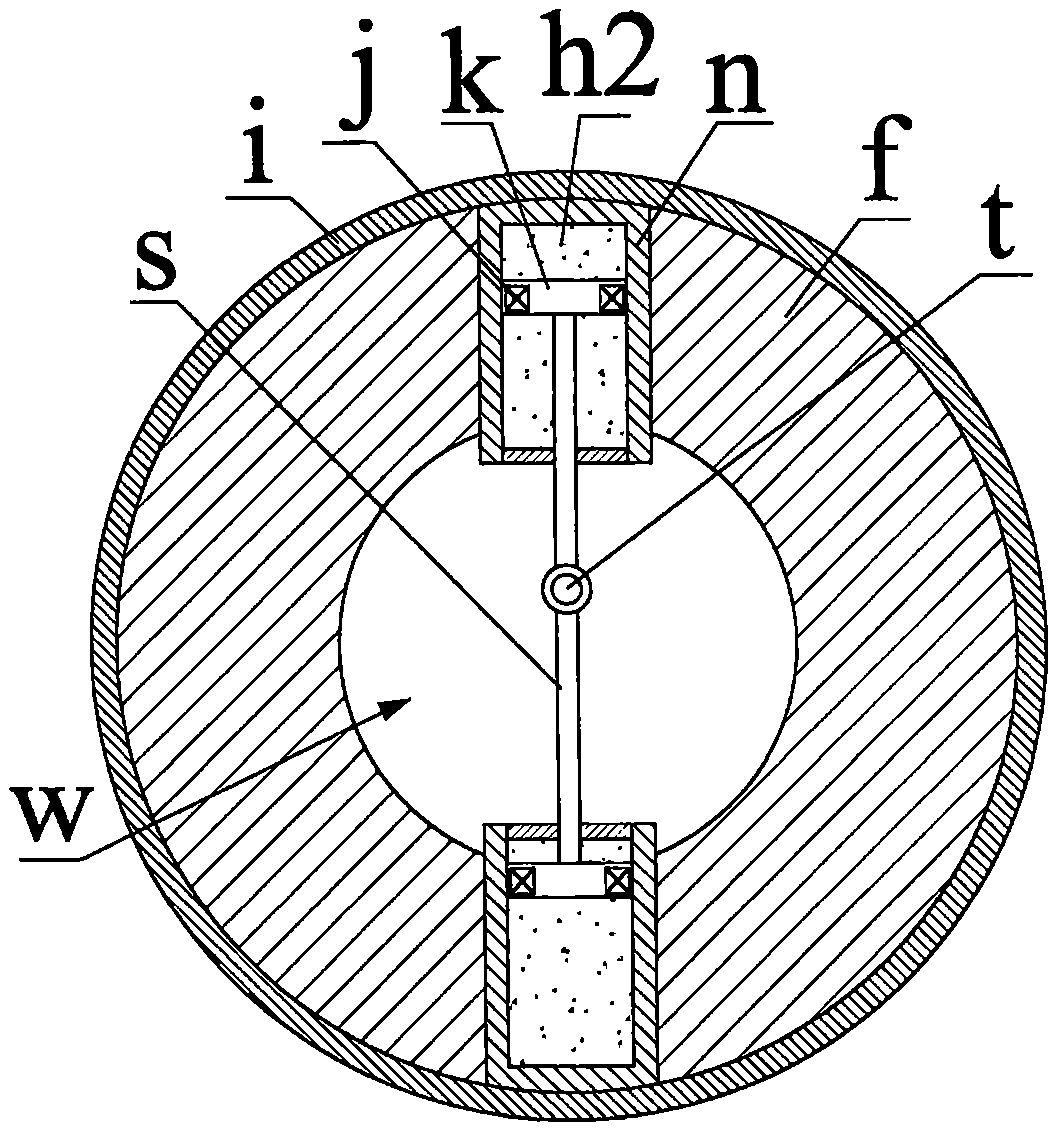

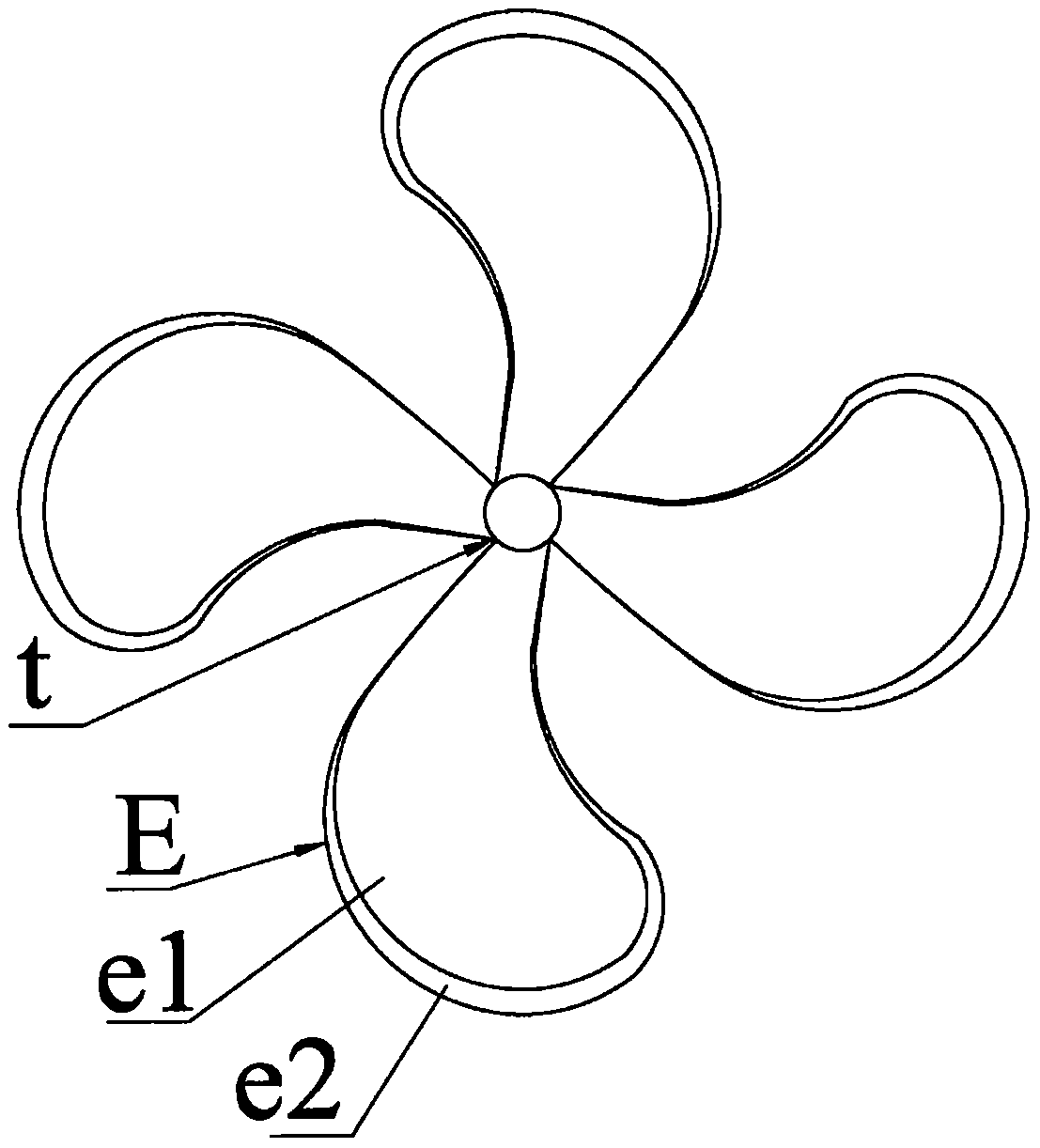

[0014] A magneto-rheological muffler for motorcycles with self-supplied noise piezoelectric power generation, comprising a hollow cylinder V, an air intake pipe a is arranged along one end of the cylinder V deviated from the axis, and an air intake pipe a is arranged along the axis of the other end of the cylinder V. There is an air outlet pipe p; the cylinder V includes a shell b and a fixed body c, and a number of cylindrical holes are opened on the fixed body c, and a magnetic cone X is arranged in the cylindrical hole; the magnetic cone X is covered by a cylindrical permanent magnet d and magnetized The conical magnetorheological fluid on the permanent magnet d is composed of h1; the cylinder V is divided into the first cavity A and the second cavity by the left partition g and the right partition m along the direction perpendicular to the axis of the cylinder V. Cavity B and the third cavity C, the inlet pipe a communicates with the first cavity A, and the outlet pipe p co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com