Novel arch frame quantitative yielding energy consumption connection device and manufacturing method thereof

A connecting device and a new type of technology, which can be used in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of insufficient support strength, low working resistance, unsafe operators, etc., so as to reduce casualties and economic losses, reduce Construction cost and construction period, the effect of convenient replacement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

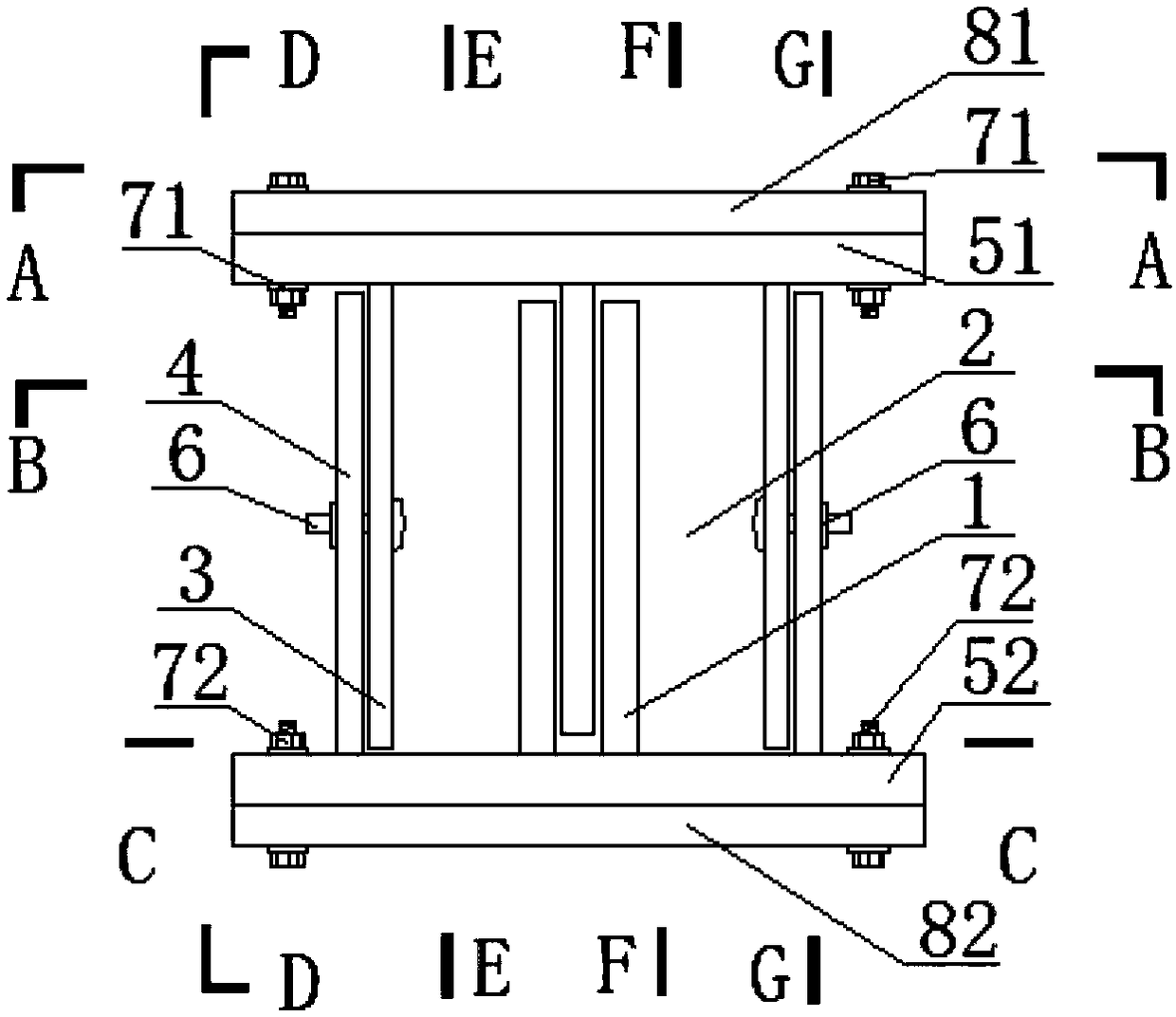

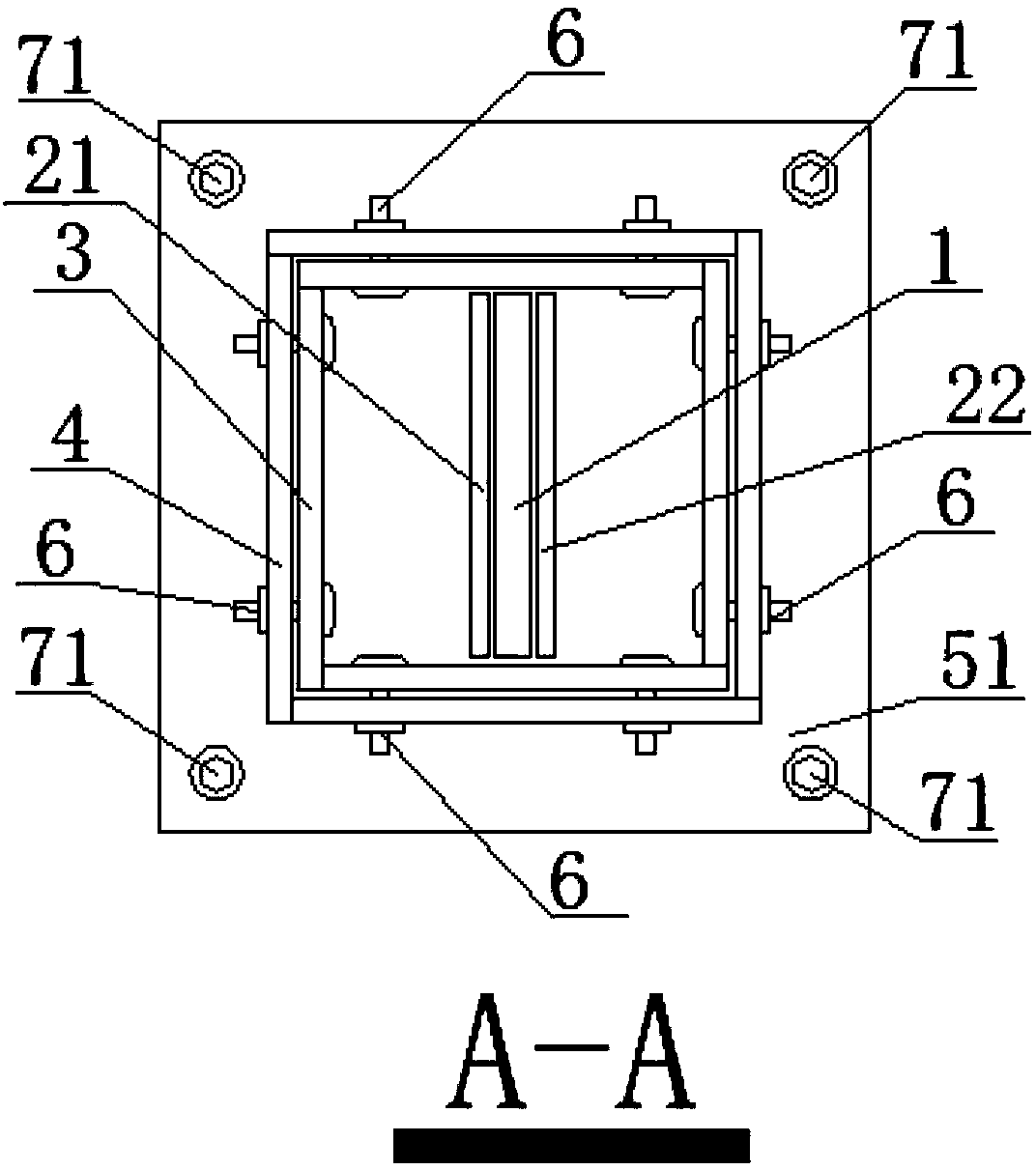

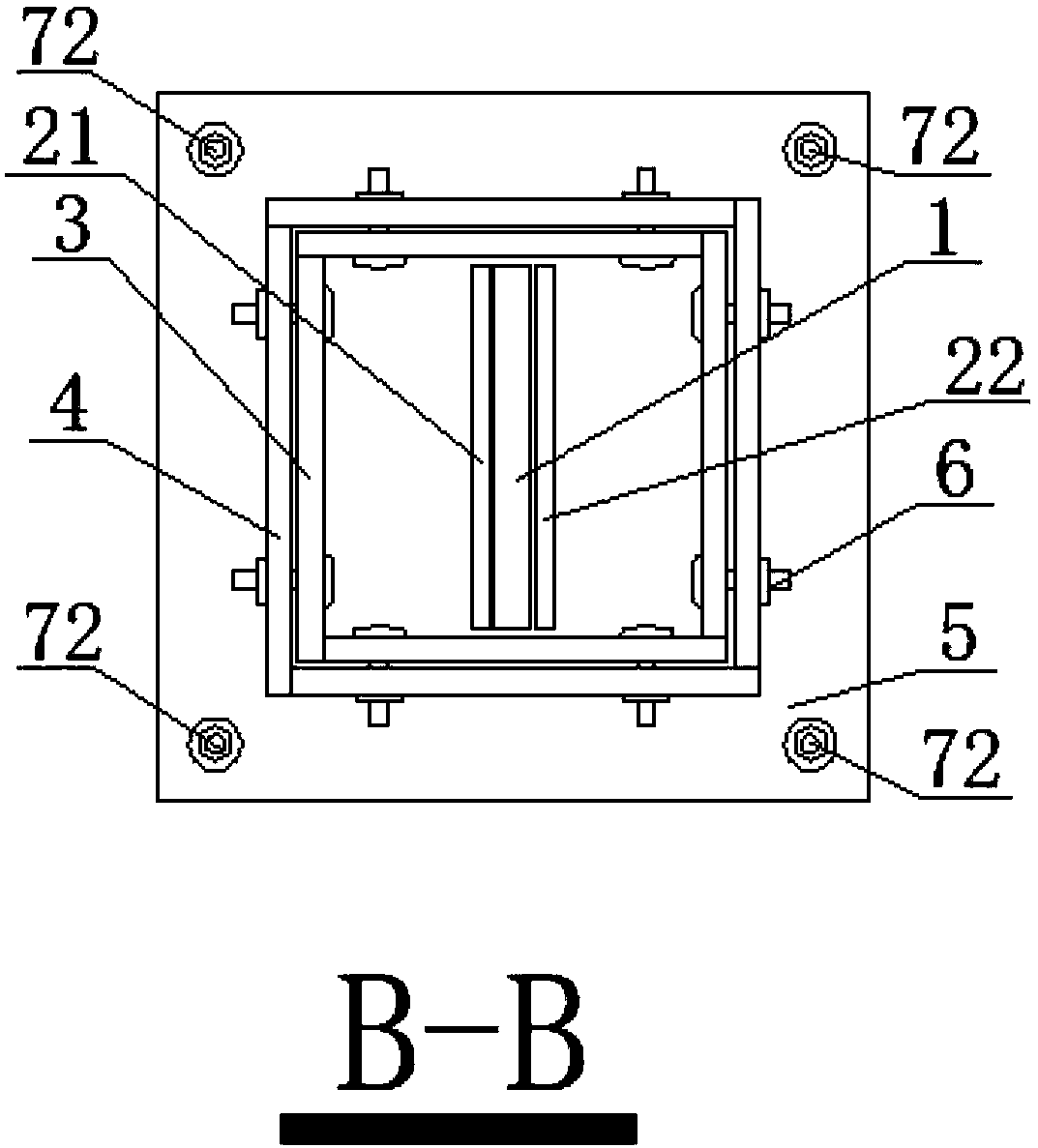

[0045] Refer to as Figure 1 to Figure 11 , a quantitative pressure loss energy connection device, comprising a main core component 1, a secondary core component 1 21, a secondary core component 2 22, an upper connecting device 3, a lower connecting device 4, an upper top plate 51, a lower bottom plate 52, and joints Connecting device 6, sliding hole 1 31, sliding hole 2 41, upper connecting bolt 71, lower connecting bolt 72, upper arch structure plate 81, lower arch structure 82;

[0046] The main core component 1 is fixedly connected to the upper top plate 51, and the secondary core component one 21 and secondary core component two 22 are connected to the lower bottom plate 52; the primary core component, secondary core component one and secondary core component Two parallel settings;

[0047] The upper connecting device 3 is connected to the upper top plate 51, the lower connecting device 4 is connected to the lower base plate 52, the first sliding hole 31 is set on the up...

Embodiment 2

[0050] A method for manufacturing a novel arch quantitatively allowing pressure loss energy connection device, comprising the following steps:

[0051] (1) Reasonable selection of materials used in quantitatively allowing pressure loss energy connection devices;

[0052] (2) Processing each component of the pressure-releasing connection device, the main core component and the secondary core component are subjected to precise machining, and the surface should be sandblasted to make the surface more frictional;

[0053] (3) The main core component is fixedly connected to the upper roof, and the secondary core component 1 and secondary core component 2 are connected to the lower floor; the primary core component, secondary core component 1 and secondary core component 2 are arranged in parallel;

[0054] (4) The upper connecting bolts and the lower connecting bolts are respectively arranged on the upper top plate and the lower bottom plate;

[0055] (5) The joint connection devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com