Viscous damping wall

A technology of viscous damping and wall panels, which is applied in the field of viscous damping walls, can solve problems such as unstable damping coefficient, troublesome filling process, and out-of-surface deformation of interpolated panels, so as to improve construction efficiency, energy dissipation efficiency, and increase The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

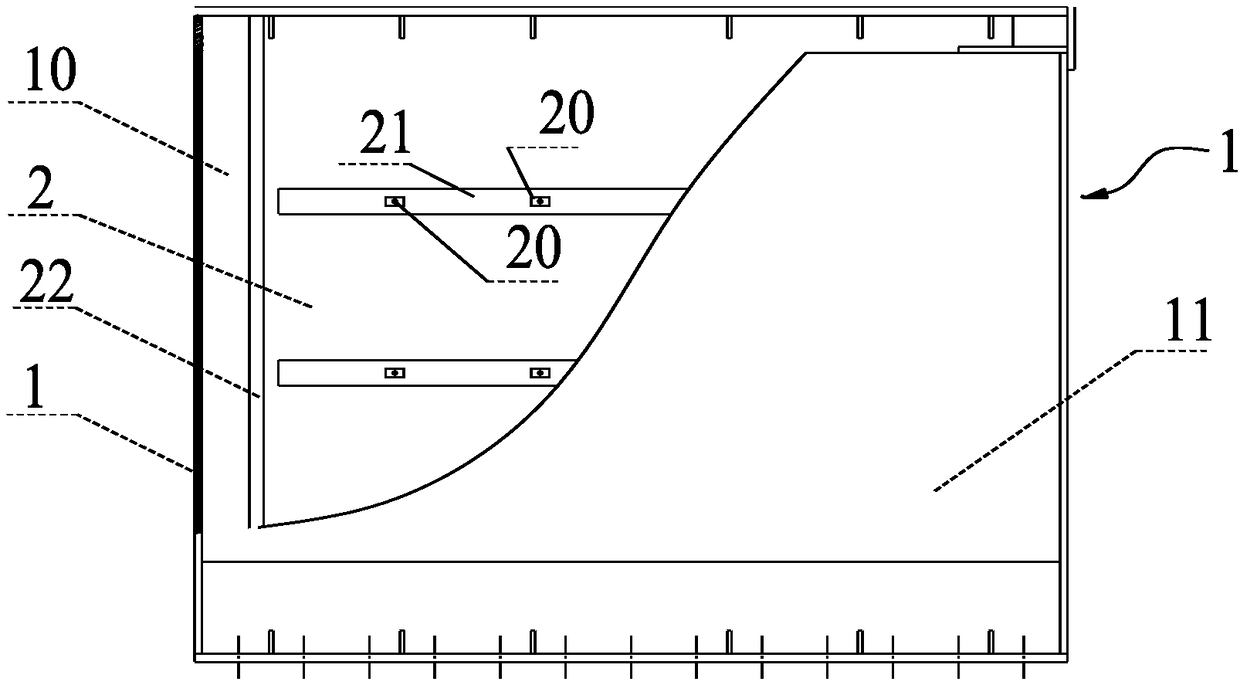

[0040] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a viscous damping wall, which includes a lower container 1 , an inner plate 2 and a resisting member 20 .

[0041] The lower container 1 includes two parallel wallboards 11 arranged at intervals, and the two wallboards 11 are connected by side walls on both sides, and a storage cavity 10 is formed between the two wallboards 11, and viscous materials are accommodated in the storage cavity 10.

[0042] The inner insert board 2 is arranged in the storage chamber 10, and the inner insert board 2 is parallel to the wallboard 11. When the viscous damping wall is subjected to vibration and the inner insert board 2 moves relative to the storage chamber 10 and the wallboard 11, due to the inner The inserting board 2 is parallel to the wallboard 11, and the inner inserting board 2 can move parallel to the wallboard 11, which ensures that the viscous material can better absorb energy. In order ...

Embodiment 2

[0047] see image 3 and Figure 4As shown, the difference between the viscous damping wall provided by the present invention and the first embodiment is that the resisting member 20 elastically resists on the wall panel 11 . When the resisting member 20 only slides and resists but does not have elasticity, when the damping wall is subjected to vibrations and other effects, the inner insert board 2 will move relative to the receiving cavity 10, and the inner insert plate 2 will be easily stuck in the receiving cavity 10. After the inner board 2 is stuck in the receiving chamber 10, the inner board 2 cannot move relative to the receiving chamber 10, cannot be hindered by the viscous material, and finally cannot normally dissipate energy. The elastic member is provided so that the resisting structure can elastically resist against the inner wall of the receiving chamber 10. During the vibration process, when it encounters a position that is easy to be stuck, the resisting member...

Embodiment 3

[0054] see Figure 6 As shown, the present invention provides a viscous damping wall, which differs from Embodiment 2 in that: the lower container 1 is provided with two parallel interposers 2, and there is a gap between the two interposers 2. A wall panel 11 is provided. When the construction party needs a larger damping force, three wall bodies 11 connected by side walls can be provided, and viscous material can be filled between two adjacent wall bodies 11 and interposers 2 can be arranged at intervals. When this embodiment is subjected to vibration, the two inner panels 2 in the wall 11 will move in the viscous material at the same time. Compared with one inner panel 2, it provides a greater damping force, and the energy dissipation will be more efficient. And due to faster performance, the wall is more stable.

[0055] Further, more than four walls 11 can be arranged in the viscous damping wall, and viscous material and interposer 2 can be filled between the walls 11 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com