Assembly type combined wall with sash type light steel frames, punched thin steel plates and foamed concrete

A technology of foamed concrete and steel pipe concrete, applied in walls, building components, buildings, etc., can solve the problems of poor seismic capacity, brittle failure, and low bearing capacity, and achieve simple construction, increased lateral stiffness, and good seismic capacity. The effect of bearing capacity and seismic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

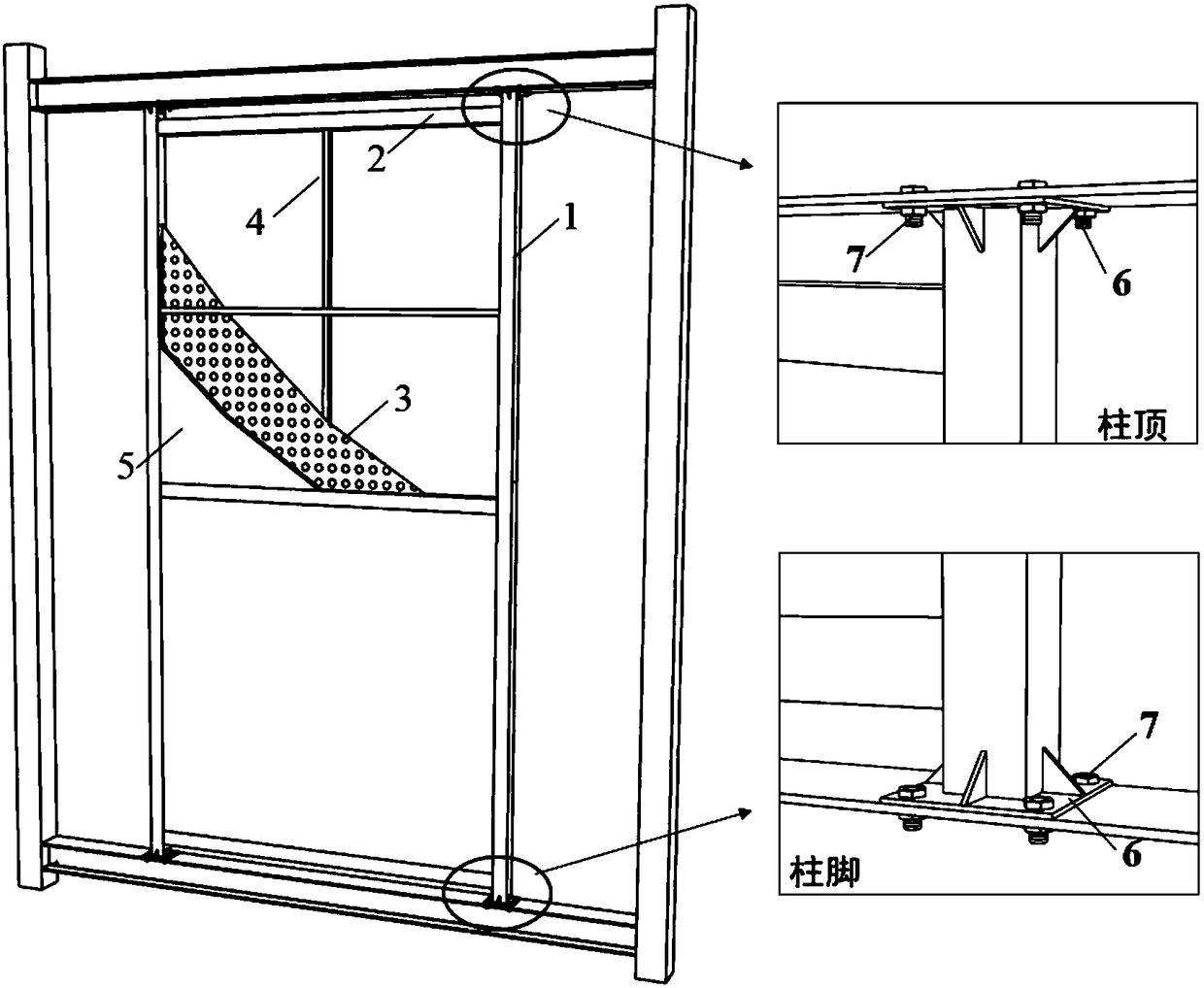

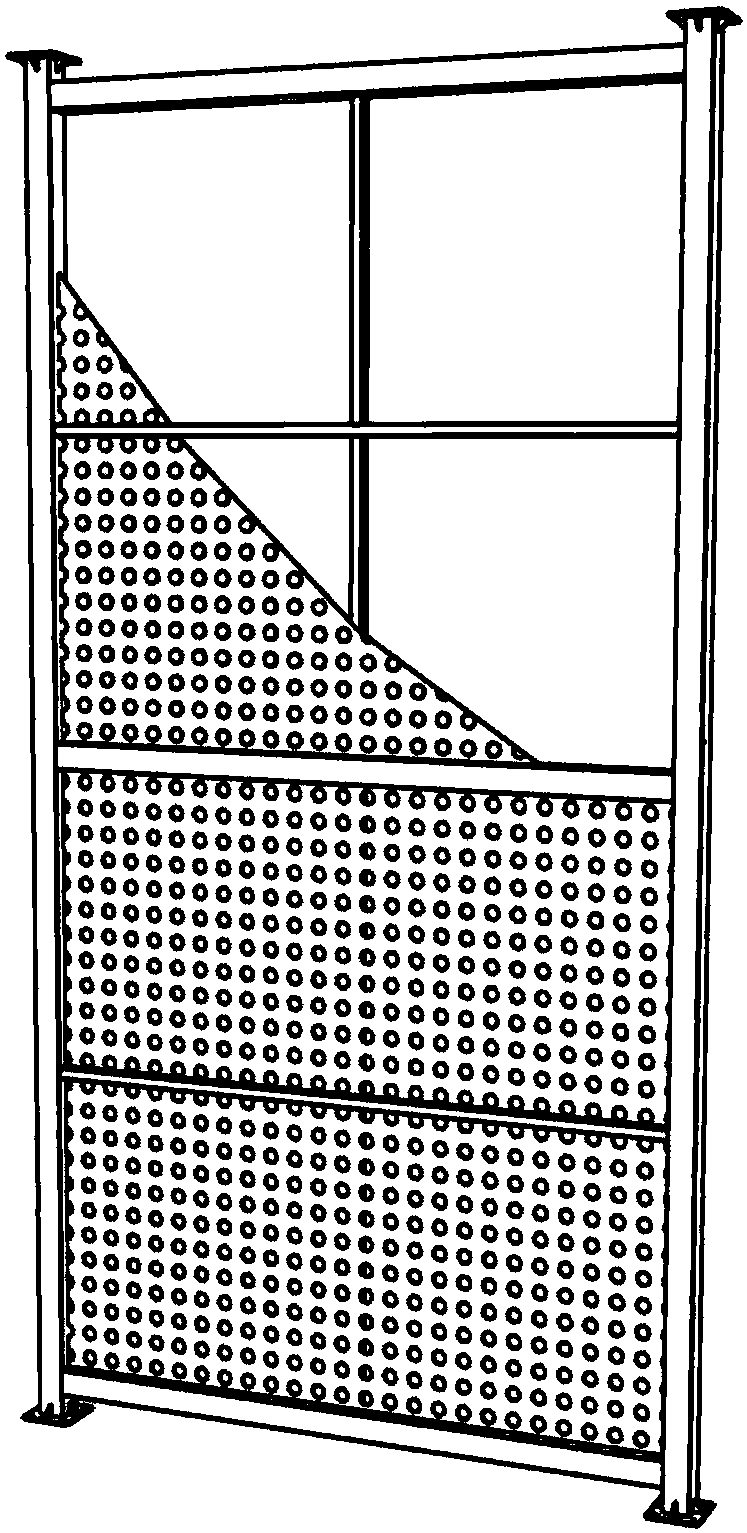

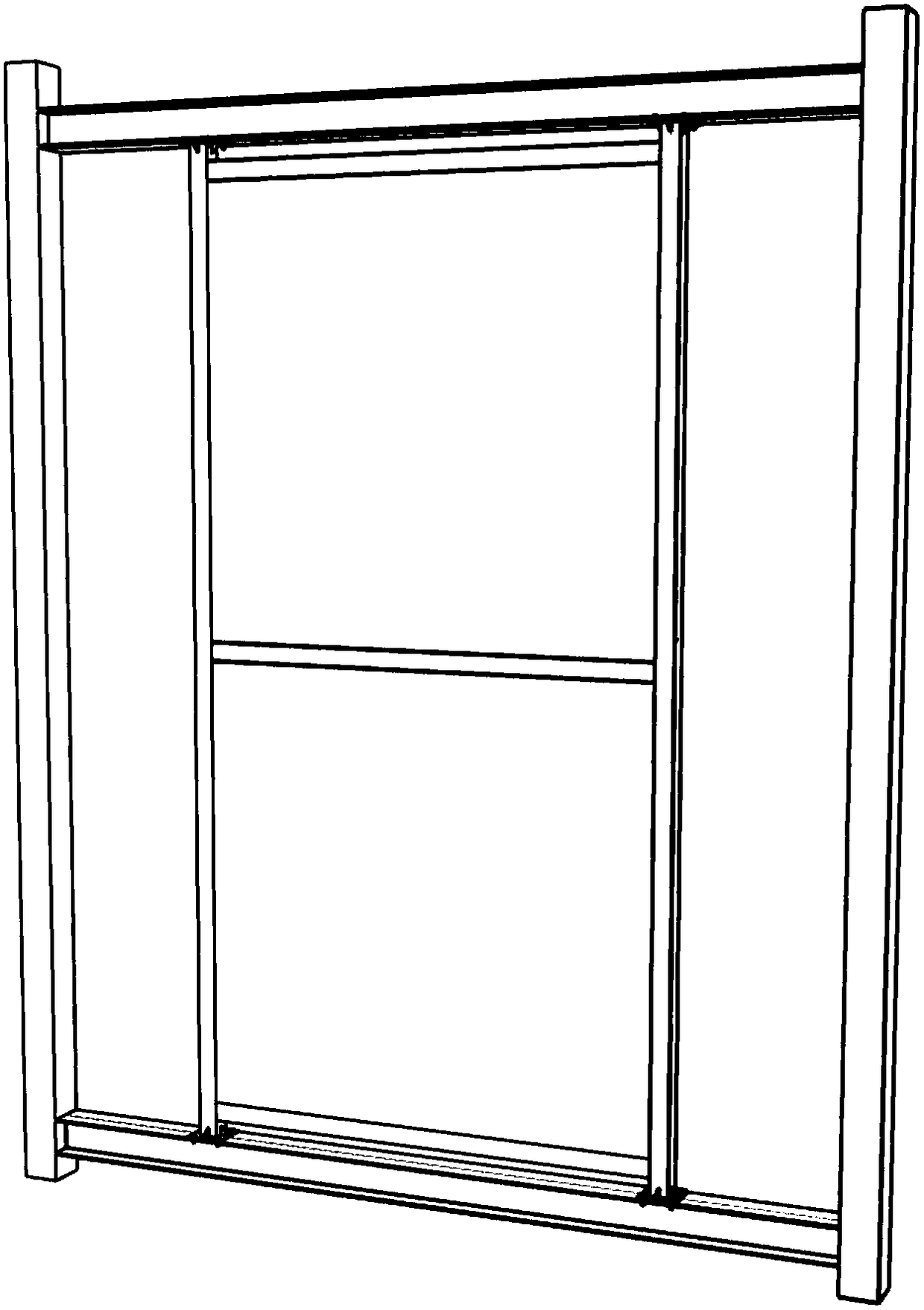

[0028] The assembled sash-type light steel frame-perforated thin steel plate-foamed concrete composite wall in the invention, combined with the attached Figure 1~3 The preparation method of the present invention is set forth as follows:

[0029] Step 1: Concrete is poured into the steel pipe and cured to form the steel pipe concrete frame column of the wall panel, the steel pipe concrete frame beam and the steel pipe concrete rib of the wall; the bolt holes corresponding to the diameter of the connecting bolt are processed on the connecting end plate, and then the connecting end The plates are respectively welded on the top and bottom of each concrete-filled steel tube frame column; the steel tube concrete frame column and the steel tube concrete frame beam are welded to form a composite wall light steel frame frame.

[0030] Step 2: Weld punched thin steel plates in the light steel frame frame of the combined wall, and then arrange horizontal and vertical steel pipe concrete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com