Overall-prefabricated main transformer foundation and oil pit structure used for indoor substation

An integral prefabrication and substation technology, applied in infrastructure engineering, protective devices, buildings, etc., can solve the problems of no related technology in assembly, difficulty in pouring, and difficulty in supporting formwork, so as to save concrete volume, strong bearing capacity, and stable structure good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

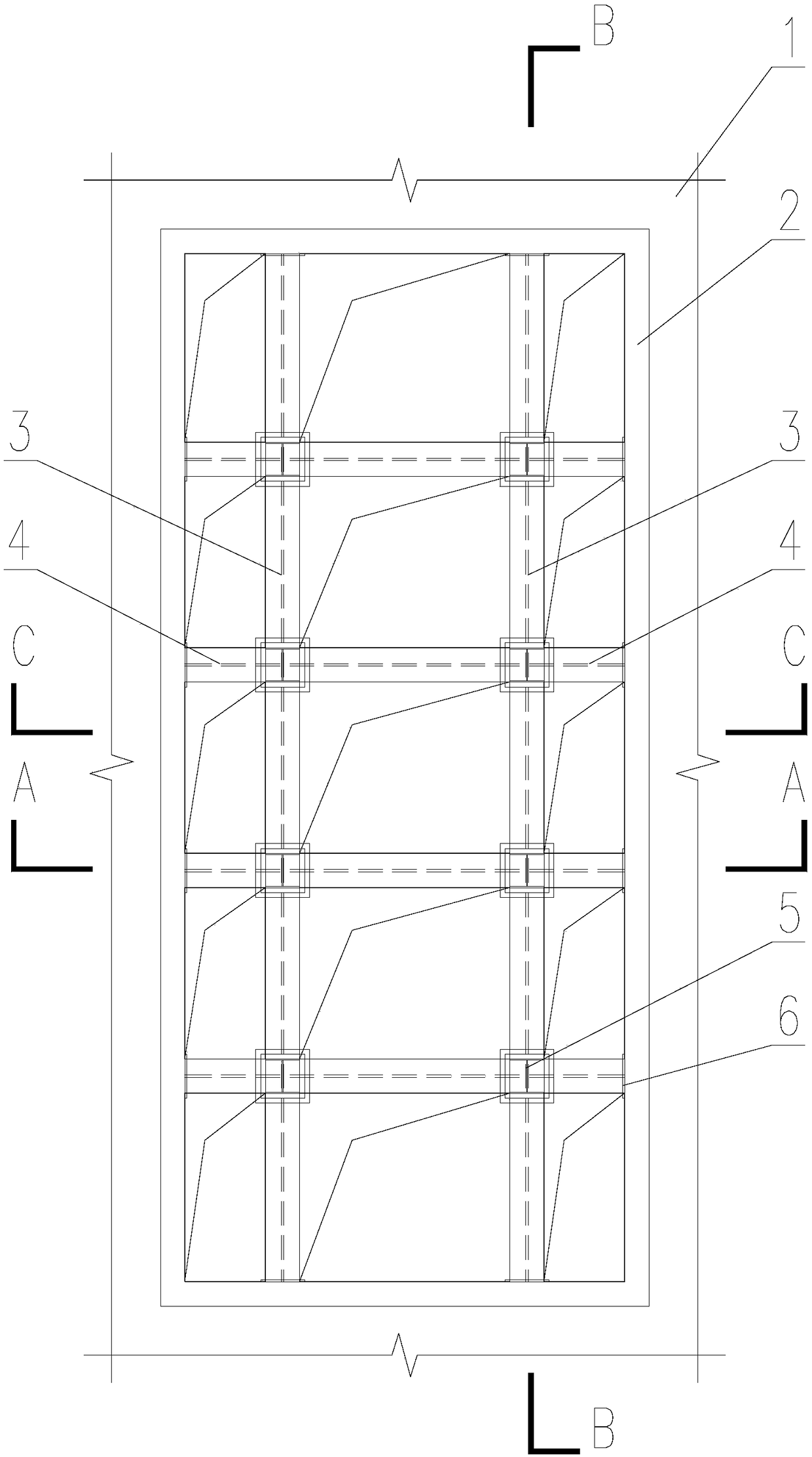

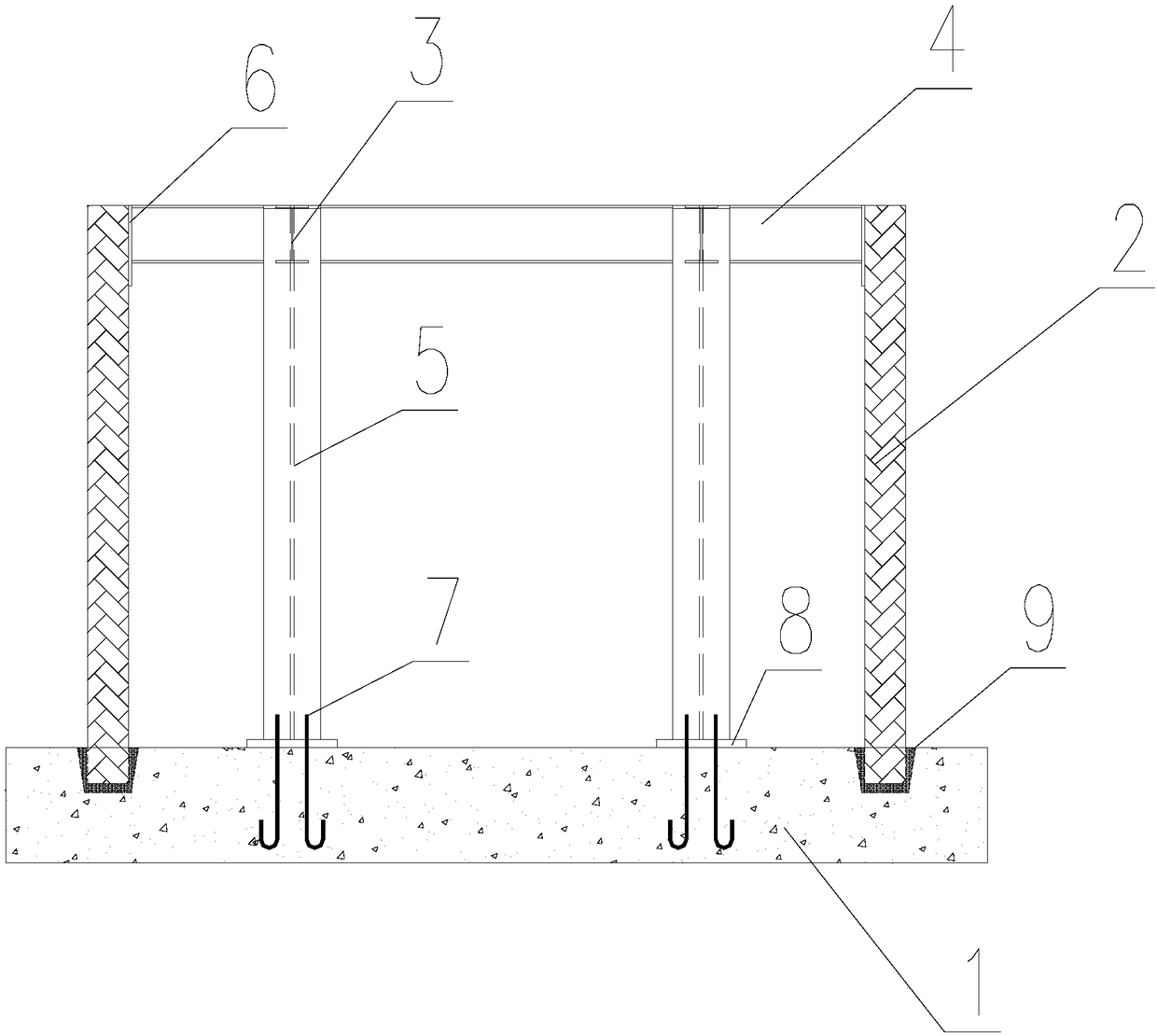

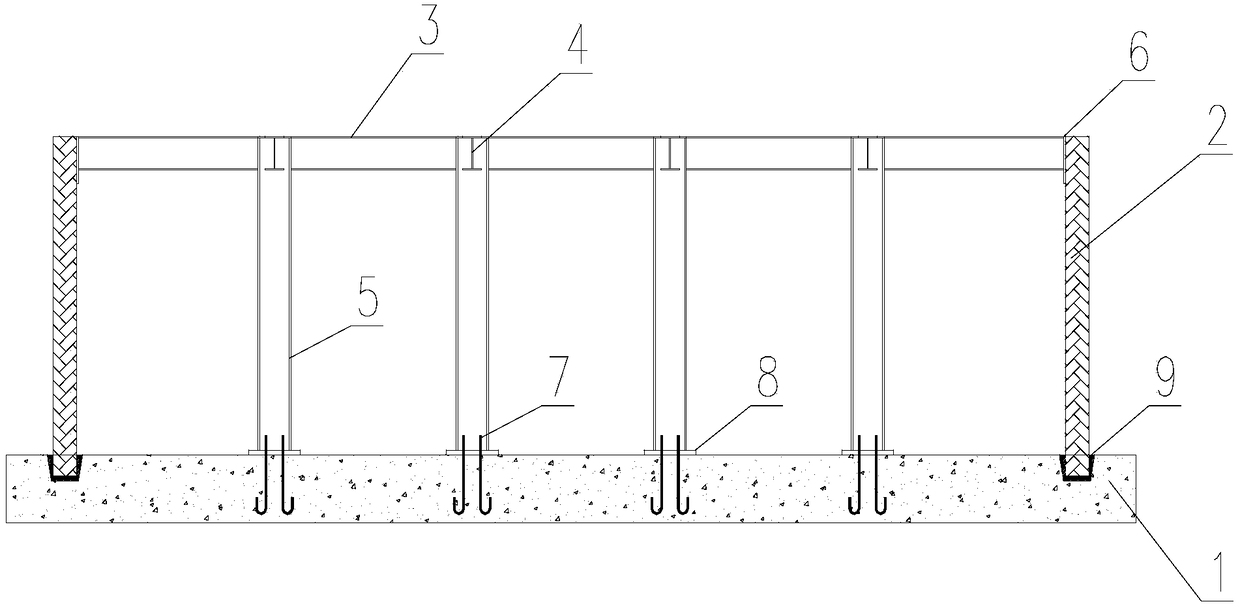

[0025] refer to figure 1 , figure 2 , image 3 , the present invention includes a cast-in-place building overall raft foundation 1, the position of the main transformer is set on the building raft foundation 1, and the anchor bolts 7 arranged in a matrix are pre-embedded. Four rows of anchor bolts 7 are pre-embedded in the direction, and two anchor bolts 7 are arranged in each row. Backing plate 8 is set on described anchor bolt 7, and foundation pile 5 is set on described backing plate 8, and the top of described foundation pile 5 connects beam 4, and the column top of described foundation pile 5 is along the length direction of building raft 1 foundation The track beam 3 is installed by welding, and the track beam 3 adopts an I-shaped steel beam. The track beam 3 and the crossbeam 4 are vertically arranged, and the oil pit wall groove is preset on the building raft foundation 1 around the main transformer, and the oil pit wall 2 is placed in the groove, and the oil pit w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com