Automatic rotation storage bin for automobile component industry robot feeding

A technology of auto parts and automatic rotation, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of production requirements such as small storage quantity, achieve the effect of improving production line tempo, convenient operation, and solving multi-product mixed line production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

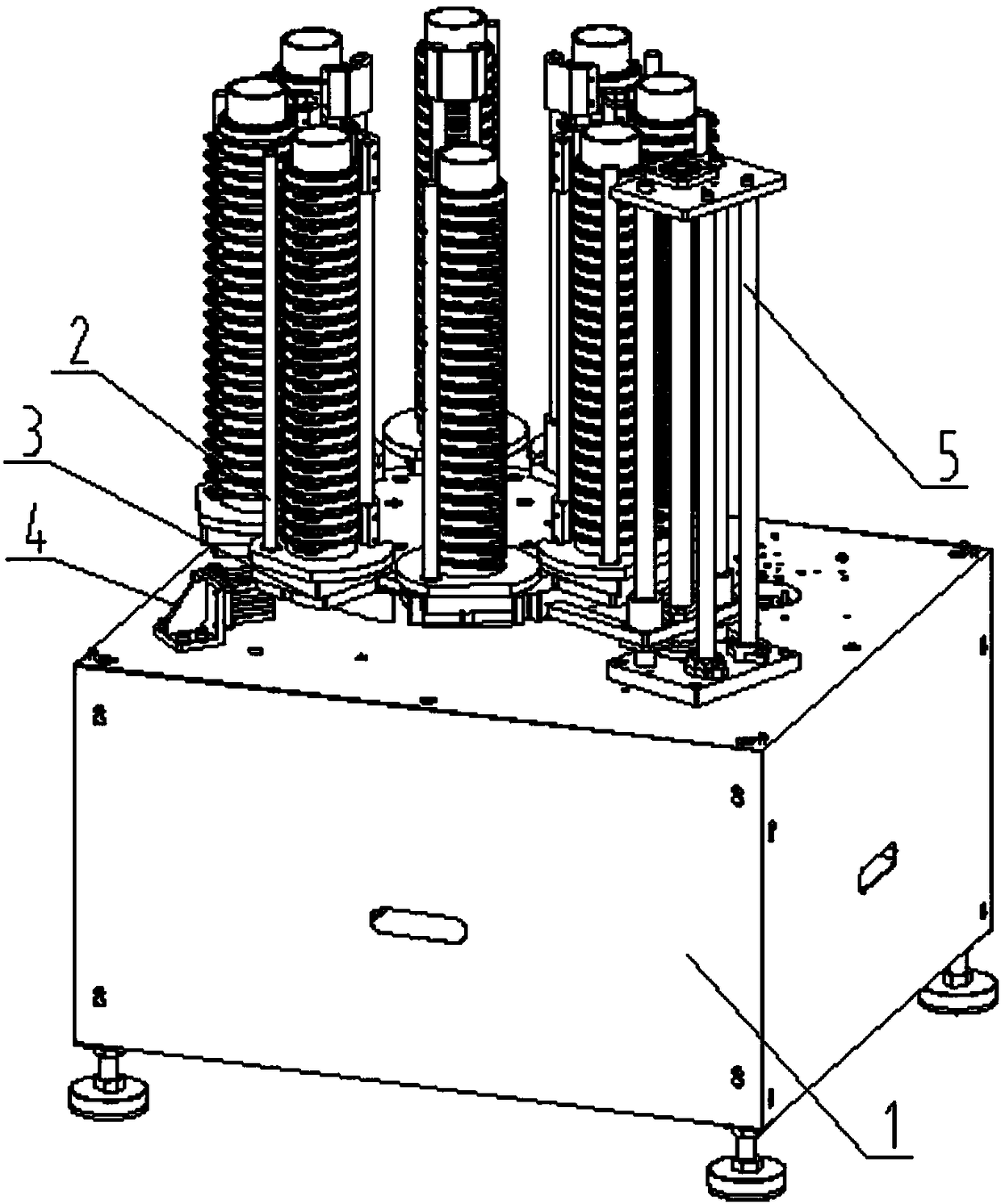

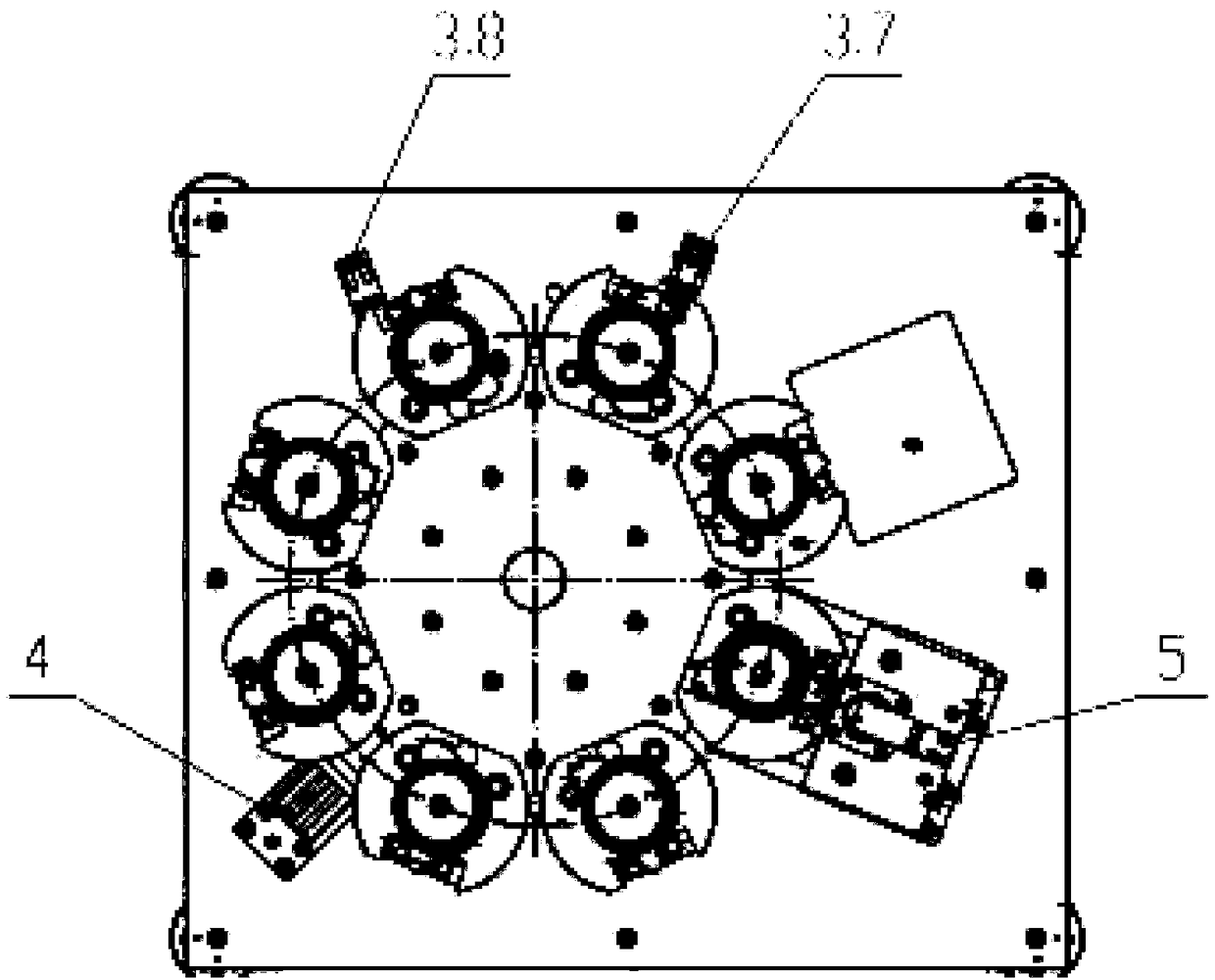

[0027] Such as Figure 1 to Figure 8 As shown, a kind of automatic rotating storage bin for the upper part of the robot in the auto parts industry includes a grabbing bin frame 1, and the middle part of the grabbing bin frame 1 is equipped with a rotating device 3 that is controlled to start and stop by induction. The upper end surface of the rotating device 3 is connected with several positioning toolings 2 evenly distributed along the circumferential direction, and the upper end surface of the grabbing bin frame 1 is also equipped with a positioning device 4 that cooperates with the rotating device 3 to position the positioning tooling 2 in place. The workpiece is lifted for the upper part lifting device 5 that the robot grabs.

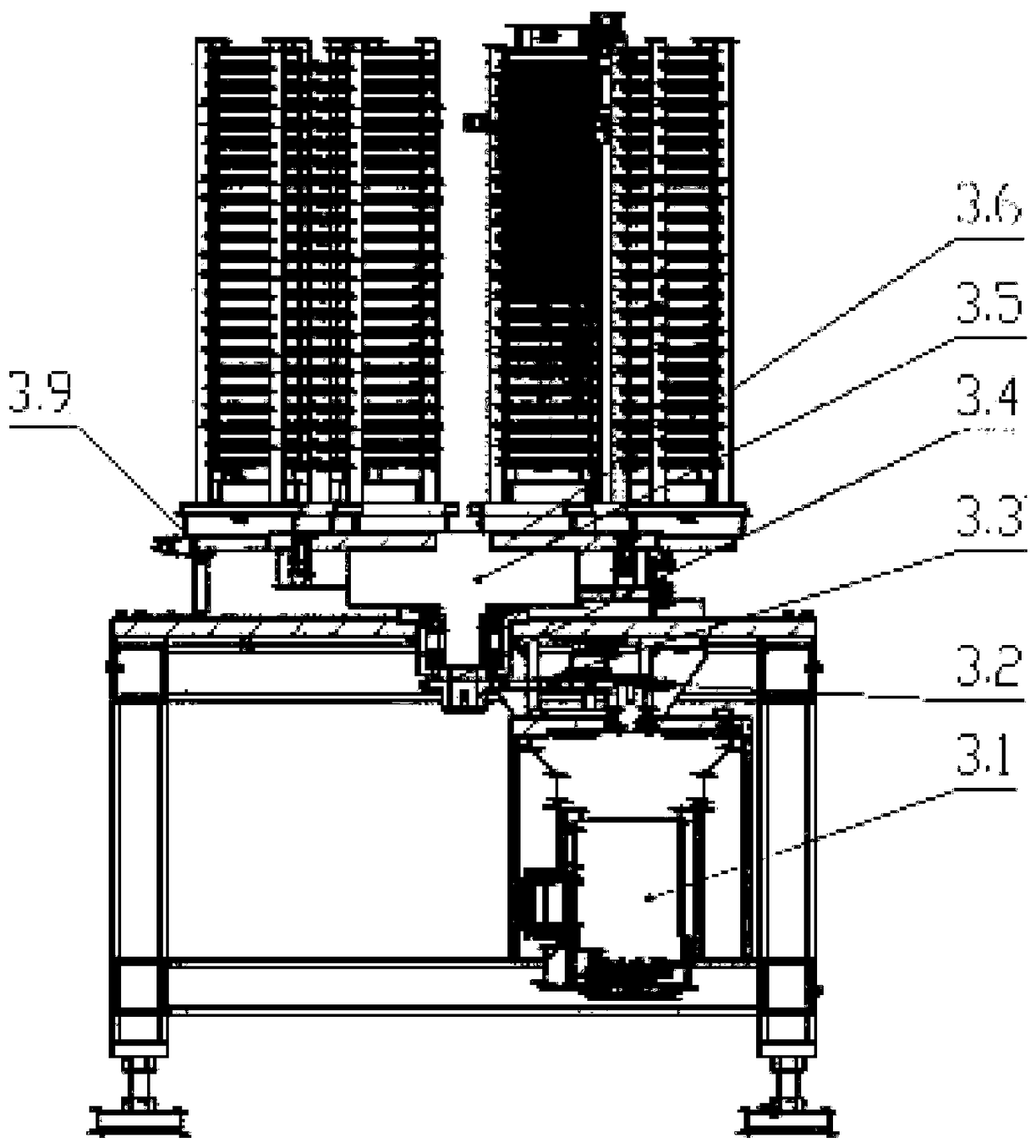

[0028] The rotating device 3 includes a turntable 3.6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com