Immersed membrane separation device and operating method thereof

A submerged and separation membrane technology, applied in the field of membrane separation, can solve the problems of insufficient and serious friction between membrane filaments, accumulation of membrane filament sludge, etc., and achieve low pollution, high energy consumption, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

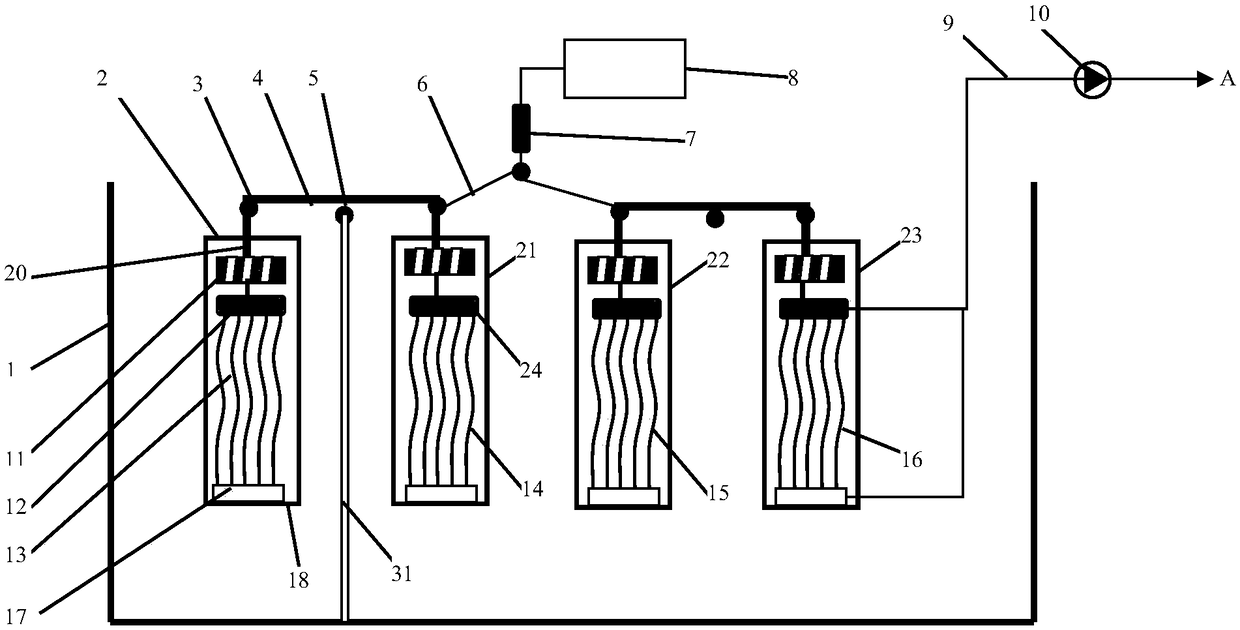

[0030] Embodiment one, such as figure 1 Shown: there are multiple membrane unit frames, shown as the first membrane frame 2, the second membrane frame 21, the third membrane frame 22, and the fourth membrane frame 23, which are respectively immersed in the water tank 1; The two cantilever ends are respectively connected to the upper ends 12, 24 of the membrane unit 13 and the membrane unit 14 through the rotatable connector 3 to form a balance group; 5 is the gravity balance fulcrum of the balance bar, fixed on the bracket 31; Another balance bar connects the membrane unit 15 and the membrane unit 16 to form another balance group; the two balance groups form a linkage group through the linkage rope 6 and the traction component 7 and the traction motor 8 . The improvements are: cancel the high energy consumption blower configuration of the prior art, and instead set the traction motor, the bracket 31 is vertically fixed in the water tank, can also be installed horizontally on t...

Embodiment 2

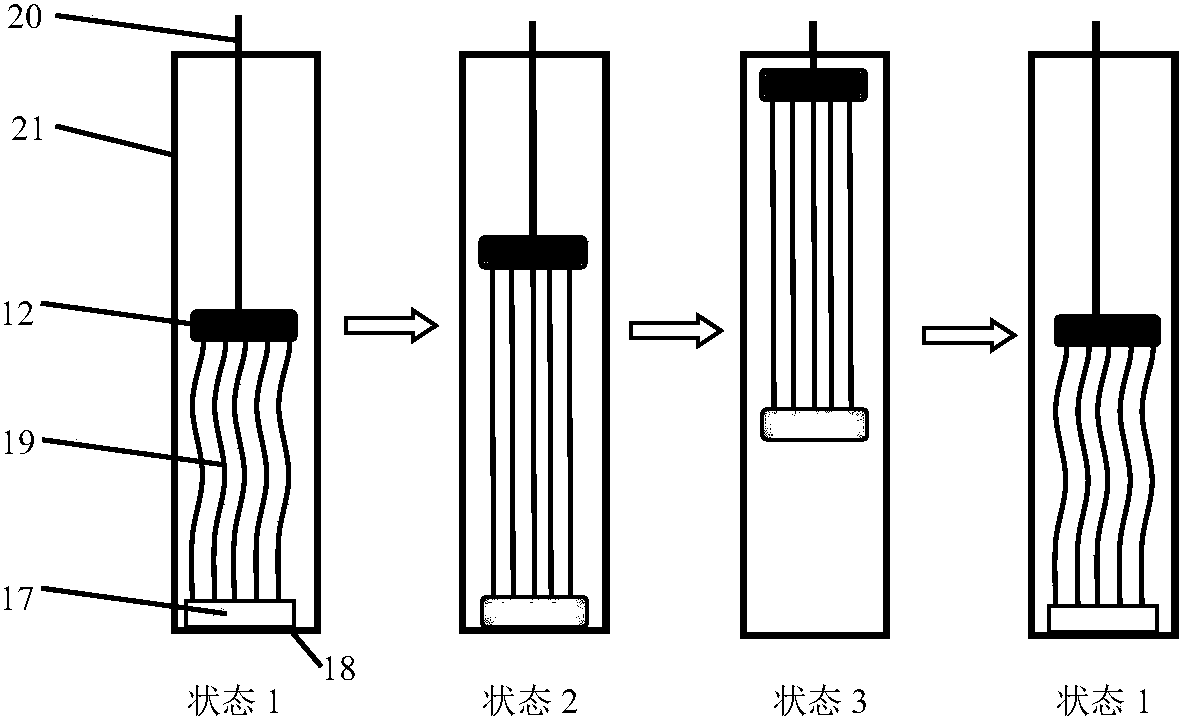

[0034] Embodiment two, such as image 3 As shown, the membrane filaments 19 in the membrane unit are pre-fixed by the pull rod 41 and are in a forced bending state. The bending degree of the membrane filament is represented by the bending amount of the membrane filament. The bending amount of the membrane filament is the maximum swing amplitude of the lateral swing displacement of the membrane filament at the half length of the membrane filament in the longitudinal direction of the membrane unit. In this embodiment, the bending amount of the membrane wire is preset to be 20 cm. When the upper end 12 of the membrane unit 13 is lifted by the traction rope 20, under the linkage action of the pull rod 41, the membrane unit as a whole is lifted from the low position 1 to the high position. 2. After the traction is stopped, the membrane unit 13 sinks under the gravity of the balance weight, and when the lower end 17 of the membrane unit sinks to the limited position 18, it returns t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com