Automatic jasmine-petal feeding unit for producing jasmine extract

A technology of jasmine petals and automatic feeding, which is applied to the production of fat, essential oil/fragrance, solid solvent extraction, etc., which can solve the problems of limited use and the inability to realize automatic transportation of plant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

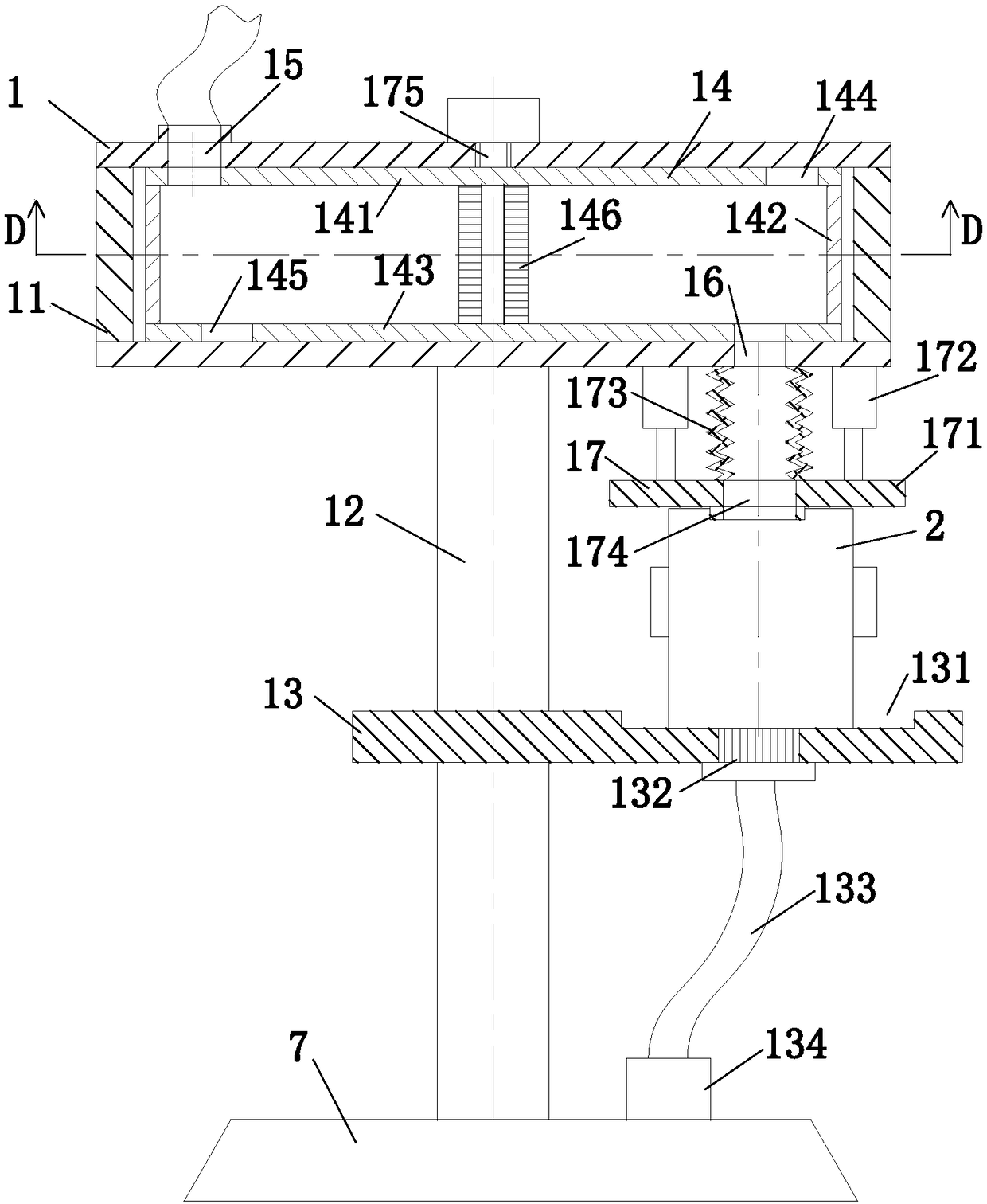

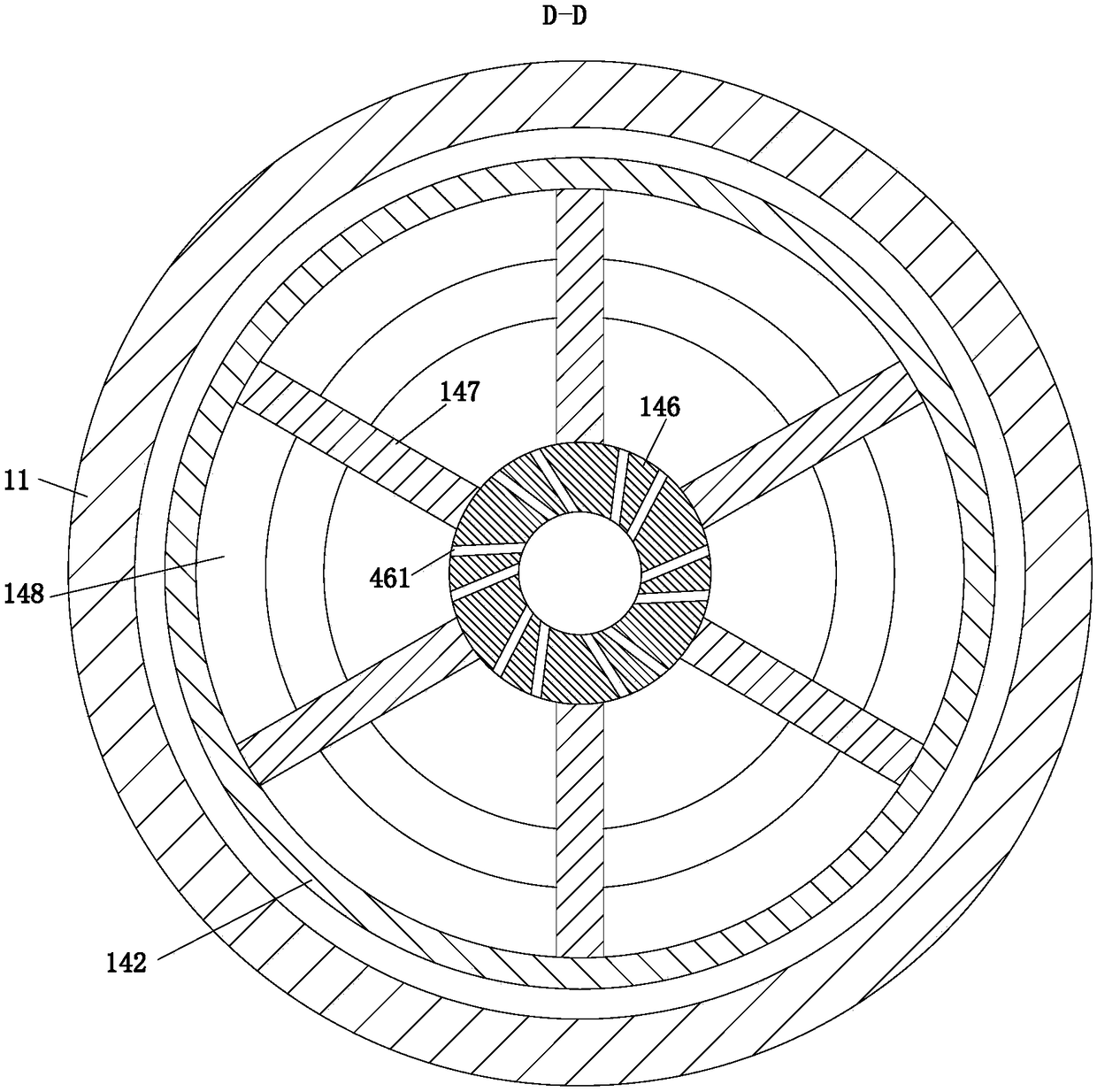

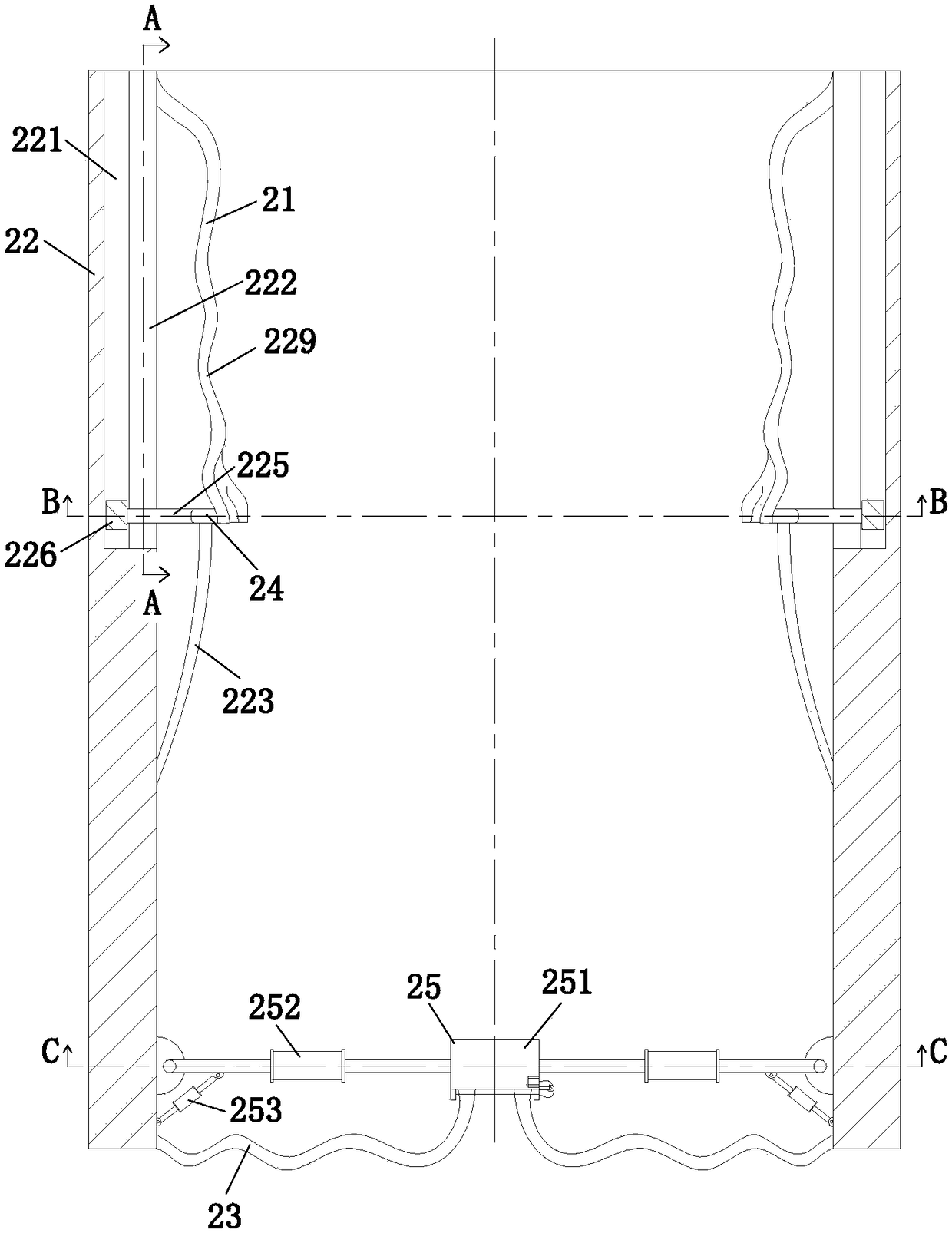

[0030] As an embodiment of the present invention, the rotating cylinder 14 includes a No. 1 upper bottom plate 141, a No. 1 side plate 142 and a No. 1 lower bottom plate 143; The upper surface of the No. 1 lower base plate 143; the surface of the No. 1 upper base plate 141 is provided with a No. 1 circular groove 144, and the No. 1 circular groove 144 is located directly below the No. 1 feed port 15; the No. 1 lower base plate 143 The surface is provided with a No. 2 circular groove 145 that runs through the No. 1 lower base plate 143, and the No. 2 circular groove 145 is located directly above the No. 1 discharge port 16; the No. 1 upper base plate 141 and the No. 1 lower base plate 143 are fixed It is connected to a No. 1 hollow column 146, and an isolation plate 147 is fixedly installed between the No. 1 hollow column 146 and the No. 1 side plate 142. The number of isolation plates 147 is six, and the six isolation plates 147 divide the rotary cylinder 14 into six parts on a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com