Reverse micro-pore forming apparatus for corneas

A device and micropore technology, which is applied in the field of medical devices, can solve the problems of corneal reverse micropore maker, the inability to accurately control the depth of tearing, and the unevenness of the tearing surface, so as to avoid irregular incision margins , easy processing, high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

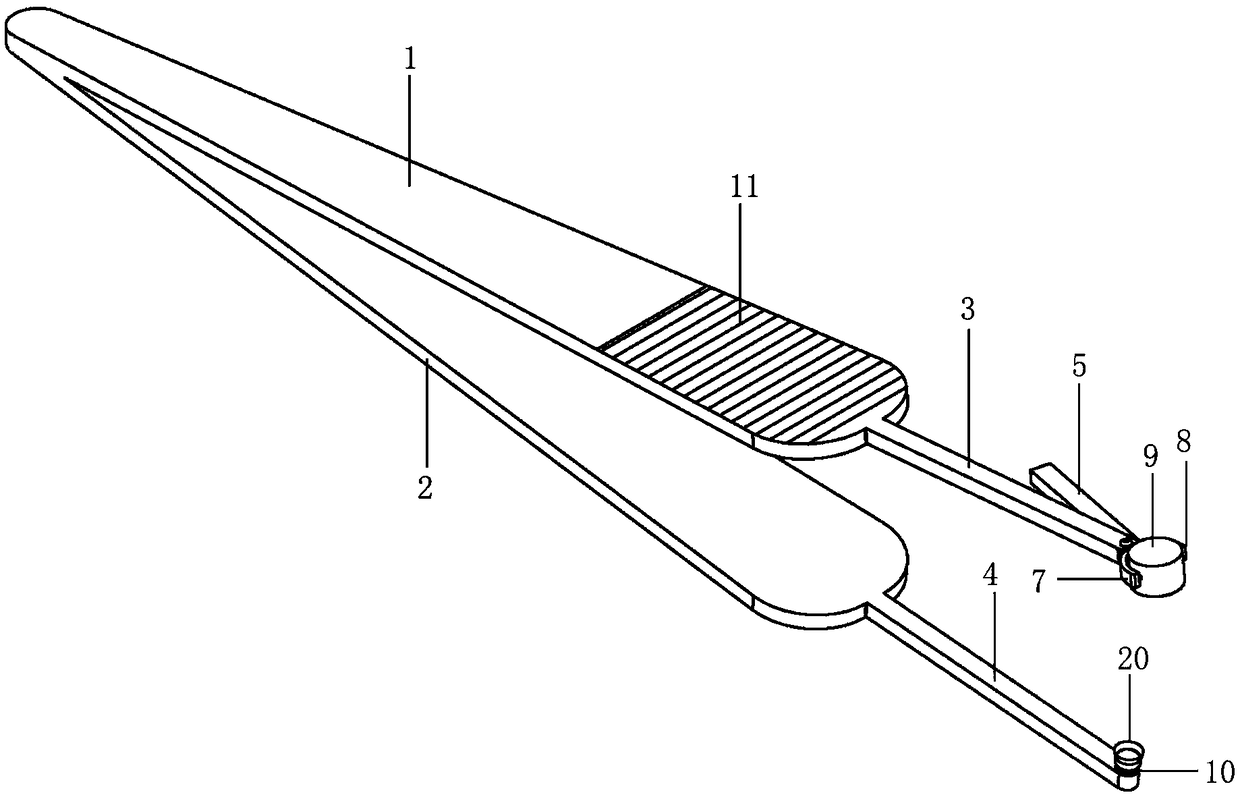

[0060] Please refer to the attached figure 1 , with figure 1 It is a structural schematic diagram of a corneal reverse micropore maker in this embodiment. The corneal reverse microhole maker includes an upper handle (1), a lower handle (2), an upper extension rod (3), a lower extension rod (4), an adjustment rod (5), a torsion spring (6), an extension rod Fixed ring (7), adjusting rod fixed ring (8), gasket (9), depth control shaft (10) and punch (20);

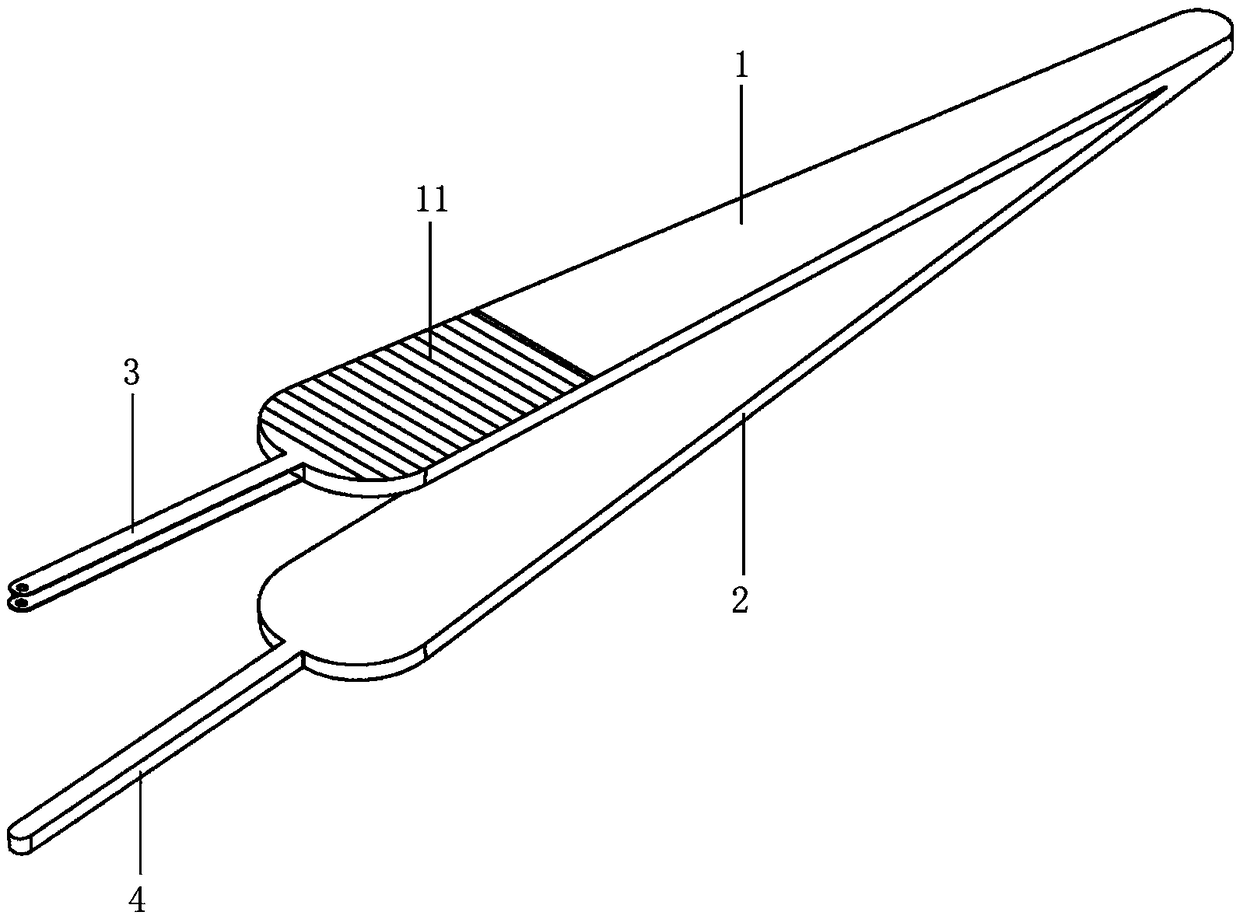

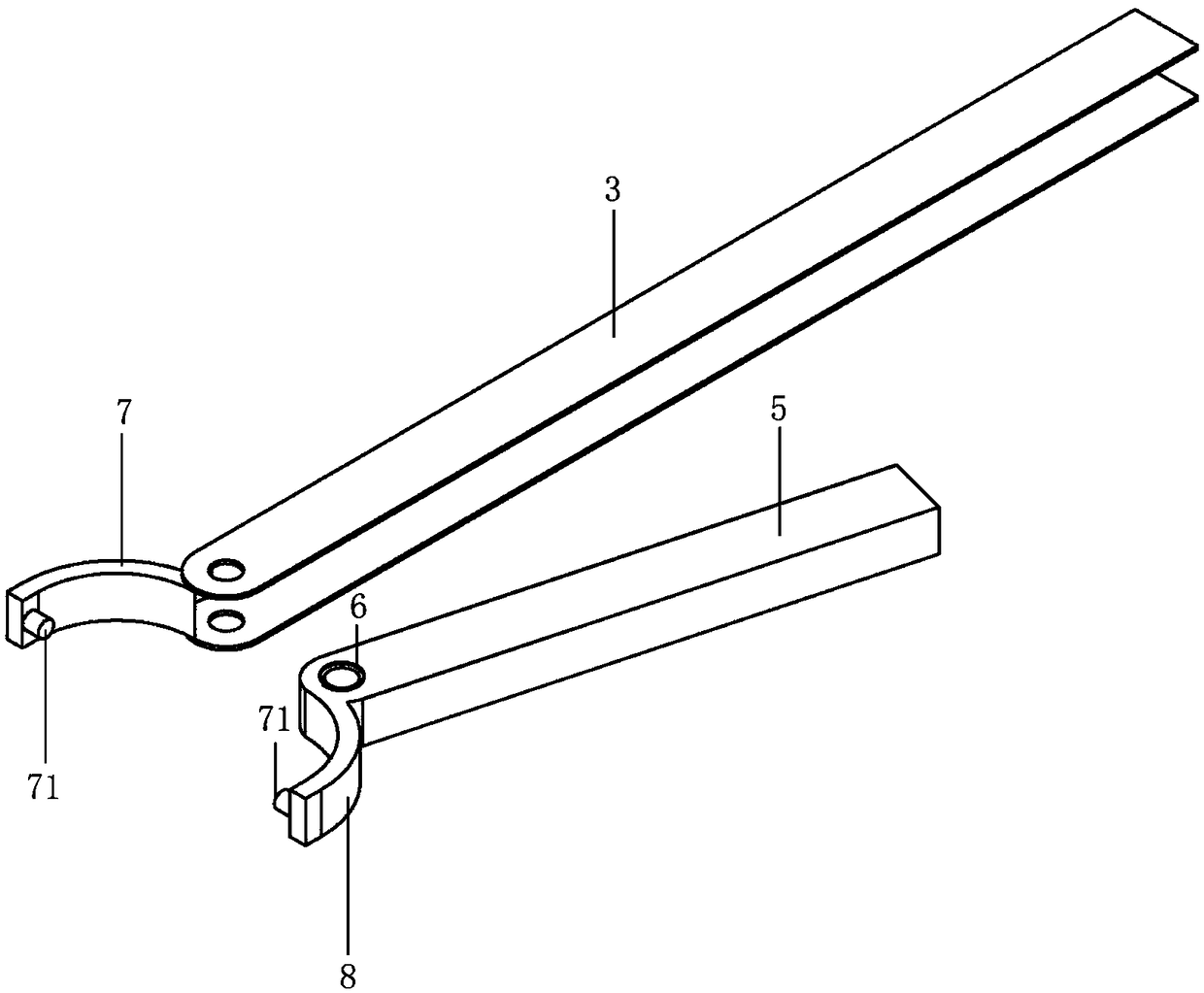

[0061] Please refer to the attached figure 2 , attached image 3 , attached Figure 8 , with figure 2 It is a schematic diagram of the combination of the upper end handle, the lower end handle, the upper end extension rod, and the lower end extension rod of a kind of corneal reverse micropore maker in this embodiment. image 3 It is a schematic diagram of the combination of the upper extension rod and the extension rod fixing ring, the adjustment rod and the adjustment rod fixing ring of a corneal reverse microhole mak...

Embodiment 2

[0066] Please refer to the attached figure 1 , attached Figure 9 , with figure 1 It is a schematic structural view of a corneal reverse micropore maker in this embodiment, with Figure 9 It is a plan view of the use of a corneal reverse micropore maker in this embodiment.

[0067] The use process and method of the corneal reverse micropore maker:

[0068] The center of the visual axis of the patient's eye was marked before the operation, and the interface between the graft and the implant bed was determined by OCT, and the thickness from the interface to the corneal endothelial surface was measured. Adjust the drilling depth.

[0069] When the depth control shaft (10) and the punch (20) are completely screwed together, the upper end of the latter is 10 μm higher than the former; according to the required depth, each time the punch (20) is screwed out one turn, the punch (20) moves up 20 μm. During the operation, positioning marks were made on the outer surface of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com