Feed for raising cattle and sheep

A feed, cattle and sheep technology, applied in the field of feed for cattle and sheep, can solve the problems of high production cost and long production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below by means of specific embodiments:

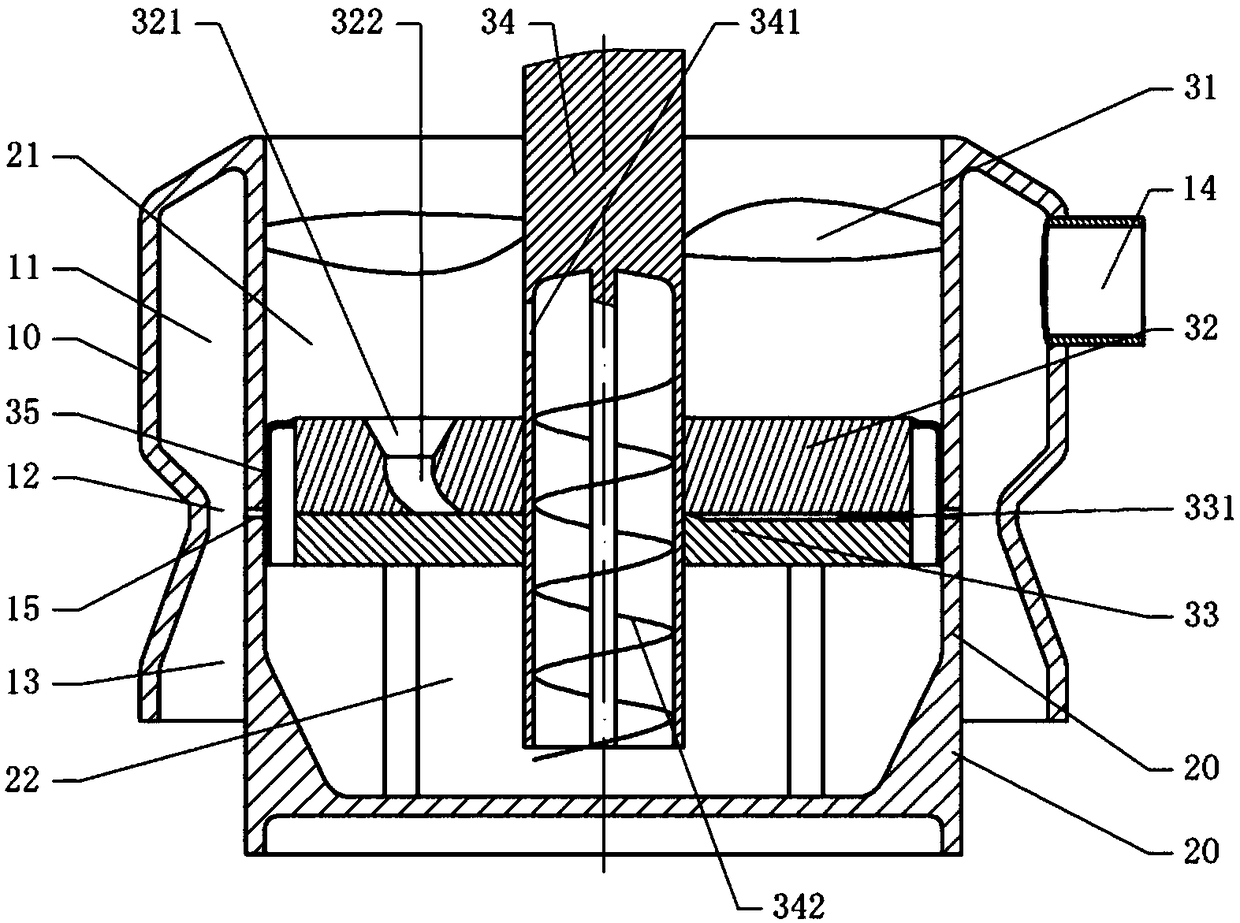

[0031] The reference signs in the drawings of the description include: outer cylinder 10, inlet section 11, throat 12, diffusion section 13, steam inlet 14, suction hole 15, inner cylinder 20, crushing chamber 21, circulation chamber 22, crushing chamber Blade 31, upper grinding disc 32, feed inlet 321, transition groove 322, lower grinding disc 33, feed guide groove 331, rotating disc 34, discharge port 341, screen mesh cover 35.

[0032] The feed for raising cattle and sheep in this embodiment consists of the following raw materials in parts by mass: 20 parts of dry hemp leaves, 30 parts of dry straw, 20 parts of protein feed, 20 parts of energy feed, 4 parts of trace element premix, 1 part of calcium hydrogen phosphate 1 part, 1 part of salt.

[0033] The specific preparation operation steps of the feed for raising cattle and sheep are as follows:

[0034] (1) Mix dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com