A kind of perovskite precursor solution and its preparation method and application

A perovskite precursor and solution technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., to achieve long service life, convenient preparation, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

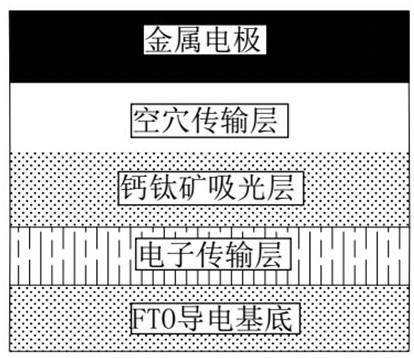

Image

Examples

Embodiment 1

[0050] The perovskite precursor is prepared according to the above method. The specific ratio of each component material is as follows: methylammonium iodide 2.97%, methylamine bromide 1.16%, formamidine iodide 7.49%, lead iodide 33.74%, lead bromide 3.79% , dimethyl sulfoxide 5.75%, N,N-dimethylformamide 17.36%, γ-butyrolactone 27.74%.

[0051] According to the preparation method in Product Example 1, the perovskite precursor solution is prepared for later use. The solution needs to be stirred continuously in an environment of 55~60°C. Then the solar cell is prepared according to the above method, and the efficiency test of the prepared solar cell is carried out. The open circuit voltage used in the test: 1.12V, the current density: 23.9mA / cm 2 ,like figure 1 As shown, the obtained solar cell efficiency: 17.01%, has a relatively high photoelectric conversion efficiency.

[0052] Stability test:

[0053] After placing the prepared perovskite precursor solution in a normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com