Method, system and device for detecting cylindricity of inner hole in stator core and storage medium

A stator core and detection method technology, applied to measuring devices, instruments, using ultrasonic/sonic/infrasonic waves, etc., can solve problems such as motor vibration, noise torque, fluctuations, etc., to avoid damage, improve measurement accuracy, and improve Effects on Performance and Productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

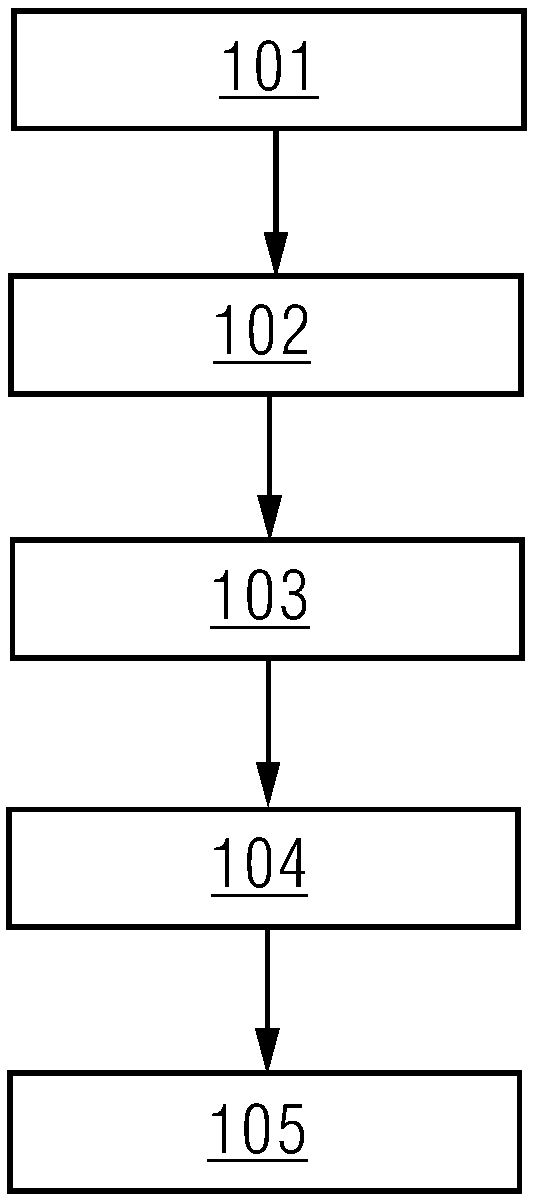

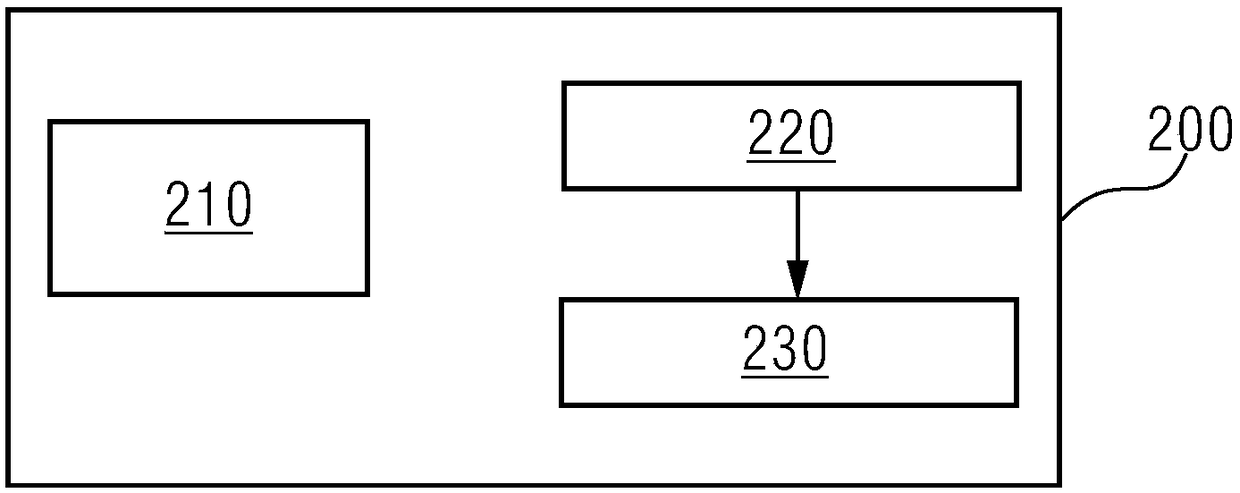

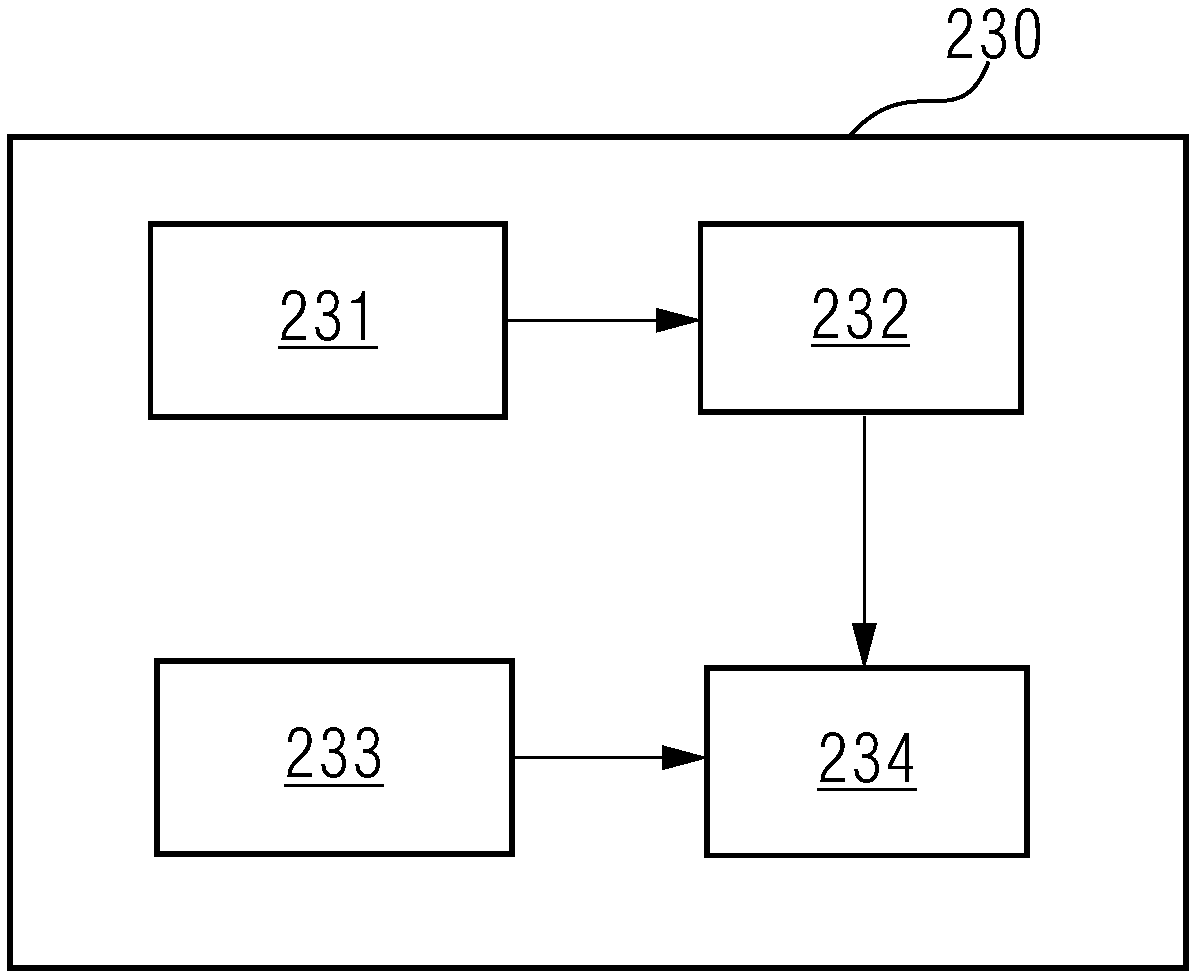

[0027] In the embodiment of the present invention, in order to provide a more accurate method for measuring the cylindricity of the inner hole of the stator core, it is considered that the characteristics of the radial vibration signal are analyzed based on the radial vibration signal of the motor in the running state. The radial vibration signal characteristics of the stator core with good inner hole cylindricity are still the radial vibration signal characteristics of the stator core with static eccentricity. In order to generate radial vibration signals, a permanent magnet needs to be assembled on the rotor, so this measurement method can be applied to permanent magnet motors. However, for non-permanent magnet motors, as long as a permanent magnet can be assembled on its rotor, this detection method can also be used to detect the cylindricity of the inner hole of its stator core. In addition, in order to avoid possible damage to the whole machine when the stator core to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com