Vehicle lamp bead and vehicle lamp refitting method

A lamp bead and vehicle technology, which is applied in the field of vehicle lighting, can solve the problems of large power consumption of halogen lamps, increase user costs, inability to achieve lighting effects, etc., and achieve good energy-saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments.

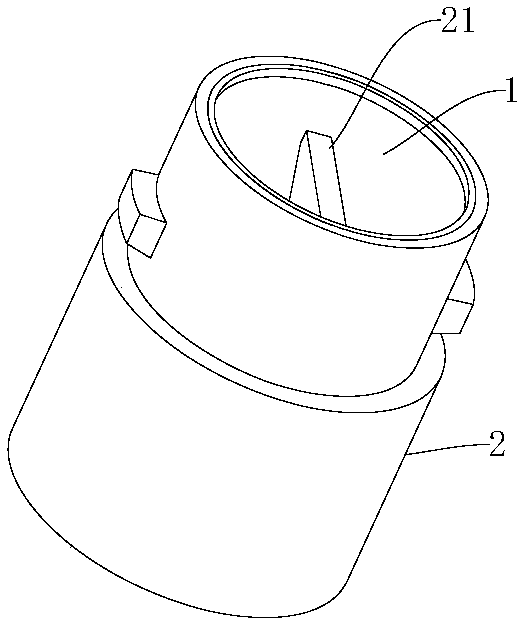

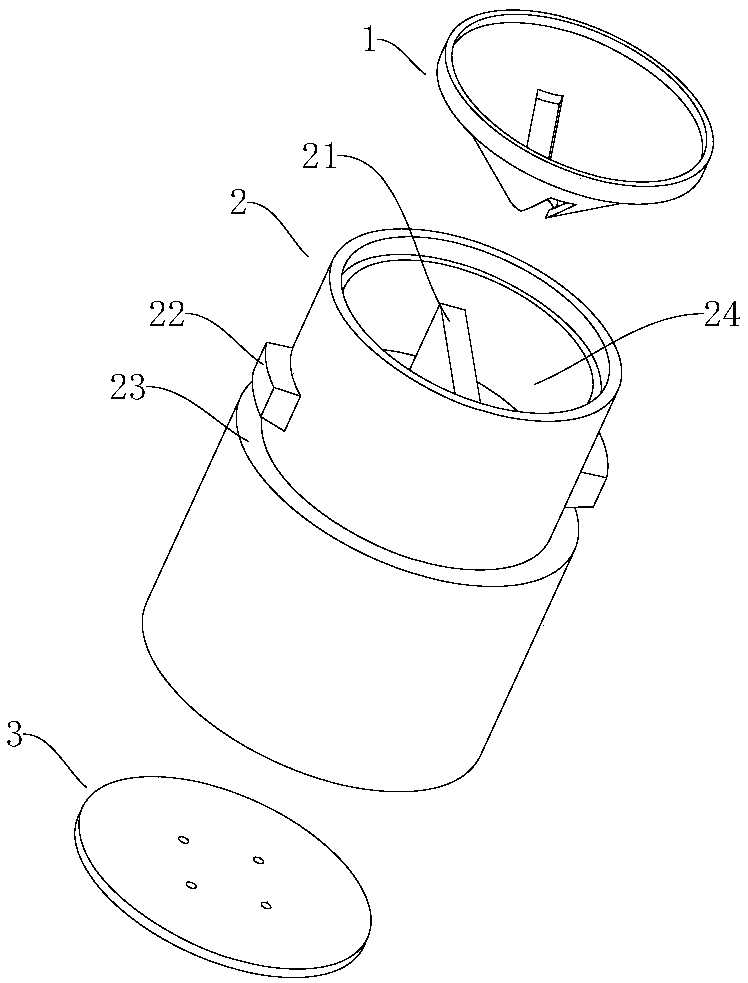

[0019] Please refer to figure 1 and figure 2 , The lamp beads for this vehicle include a light source body, the light source body is two sets of LED light sources (not shown in the figure), the lamp beads for vehicles also include a cylindrical metal body 2, the inner front end of the metal body 2 The light source cavity 24, the rear end (the lower side of the light source cavity 24 in the figure) is the power supply cavity, the light source cavity 24 is provided with a reflector 1 and a partition 21, and the partition 21 connects the reflector along the axis of the reflector 1. The space in 1 is divided into half, the two groups of LED light sources are supported in the reflector 1 and are located on both sides of the partition plate 21 respectively, and a circuit board (not shown in the figure) is installed in the power supply cavity, so the The circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com