Candan universal joint synchronization oil injection equipment and method thereof

A cross universal joint and grease technology, which is applied in the direction of mechanical equipment, elastic couplings, engine components, etc., can solve the problems of reducing the efficiency of oil injection, insufficient oil, and inability to synchronize one-time oil injection, etc., to improve oil injection efficiency, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

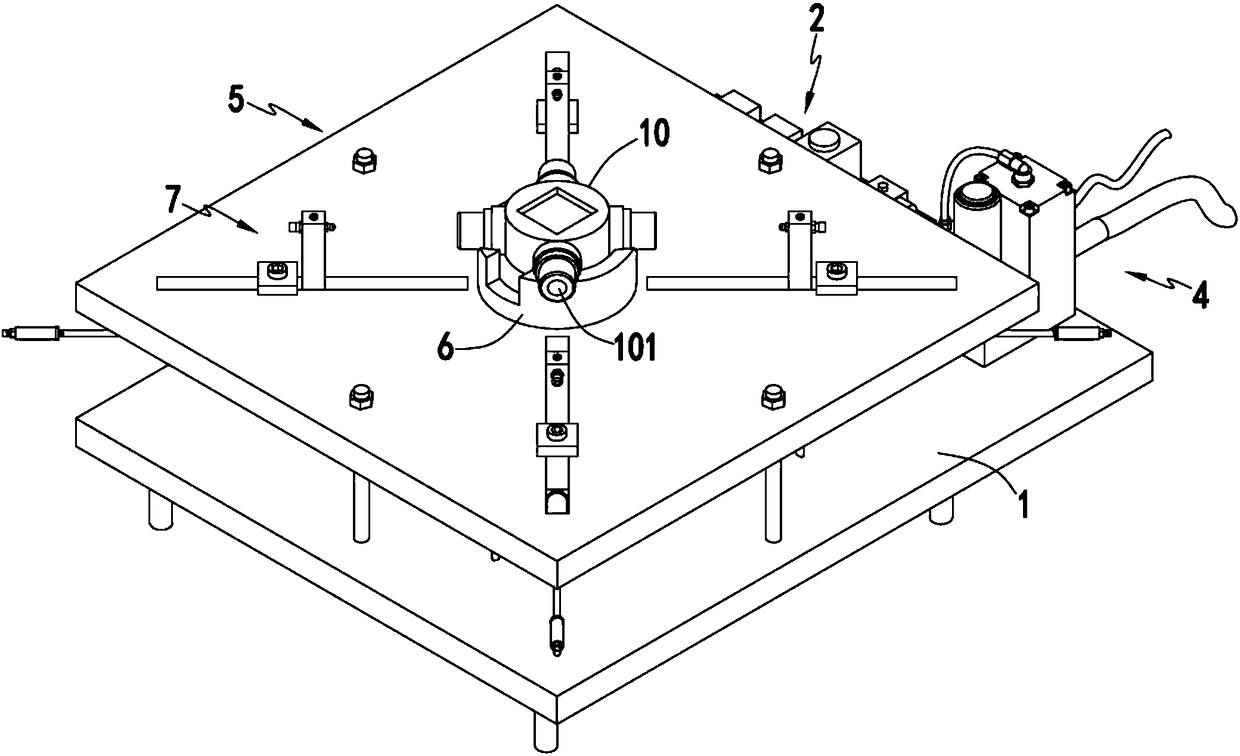

[0050] Such as figure 1 , figure 2 , Figure 5 , Image 6 with Figure 7 As shown, the synchronous grease injection equipment for cross universal joints includes a base 1, an electric control device 2 installed on the base 1, an air intake control device 3 and an oil supply device 4, and a guide support unit 5 is also arranged above the base 1. , the guide support unit 5 is provided with a positioning jig 6 for positioning the cross joint 10 to be greased, and the positioning jig 6 is provided with the same position as the oil injection hole 101 of the cross joint 10 along the circumferential path. A corresponding oil injection device 7;

[0051] A plurality of oil injection devices 7 corresponding to the positions of the oil injection holes 101 move synchronously along the radial direction of the oil injection holes 101 corresponding to the positions of the oil injection devices 7 towards the center position of the Oldham joint 10 under the control of the air intake cont...

Embodiment 2

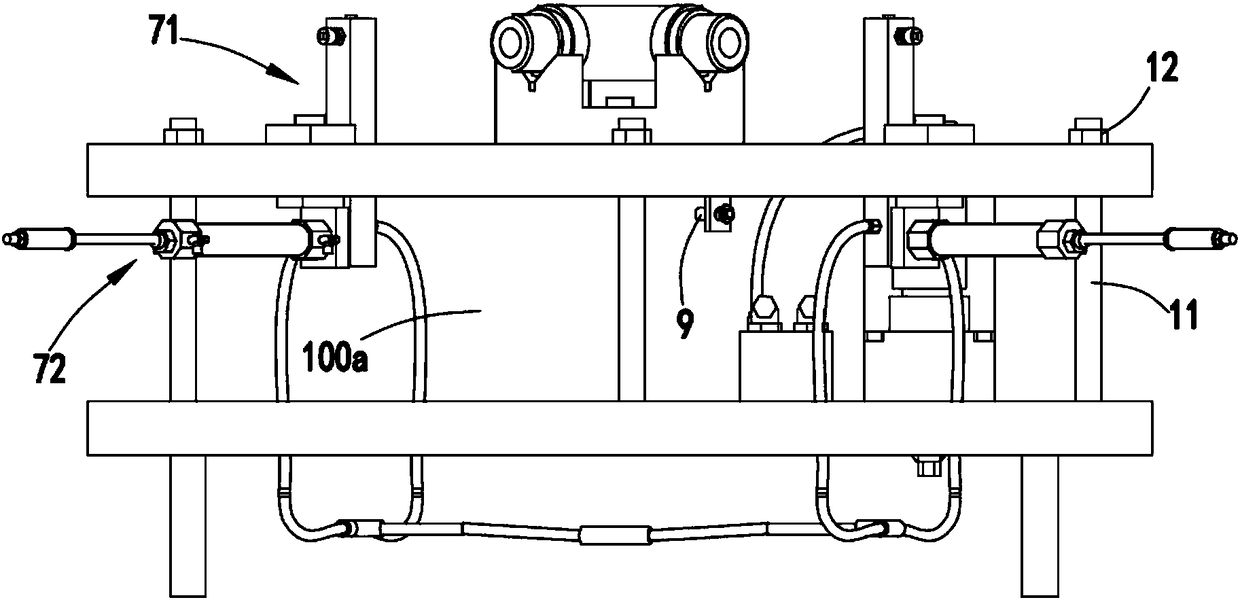

[0072] Such as image 3 with Image 6 , wherein the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between the second embodiment and the first embodiment is that: as a preference, the oil injection is performed between the oil injection mechanism 71 and the oil injection hole 101 of the Oldham joint 10 using an eccentric non-contact oil injection method.

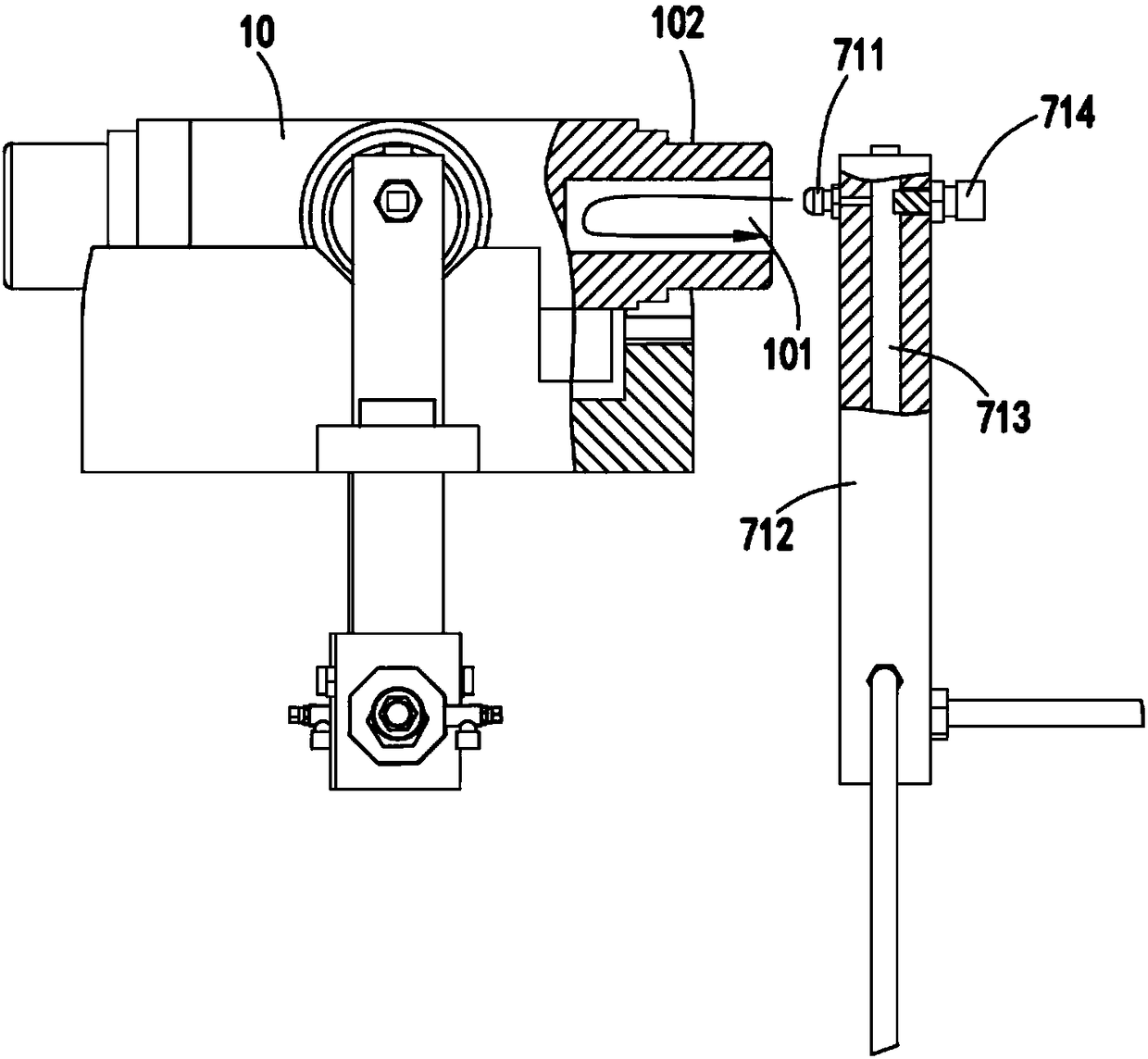

[0073] Such as image 3 As shown, further, the oil injection nozzle 711 of the oil injection mechanism 71 communicates with the oil supply device 4 through the oil passage. there is a gap between

[0074] Specifically, the oil injection mechanism 71 includes a sliding block 712 that slides along the guide groove 511 driven by the propulsion mechanism 72, the oil injection nozzle 711 is arranged on the upper end of the sliding block 712, and the i...

Embodiment 3

[0082] Such as figure 2 , wherein the same or corresponding components as those in Embodiment 2 use the corresponding reference numerals as in Embodiment 2. For the sake of simplicity, only the differences from Embodiment 2 are described below. The difference between the third embodiment and the second embodiment is: further, the vertical distance between the oil injection nozzle 711 and the support plate 51 is d2, and d2 satisfies 27cm≤d2≤30cm.

[0083] In this embodiment, the oil nozzle 711 on the sliding block 712 is set within a certain height range according to the actual production situation, so that when dealing with the oil injection processing of products of different specifications, the operator only needs to replace the fixture body 61 of different specifications and sizes. , there is no need to adjust the height of the oil injection nozzle 711 on the oil injection device 7, which greatly improves the versatility and convenience of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com