Novel hub

A new type of wheel hub technology, applied in the mechanical field, can solve the problems of enlarged size, large riser, long manufacturing cycle, etc., and achieve the effect of reducing the wind resistance area, increasing the fan efficiency, and having a consistent installation angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

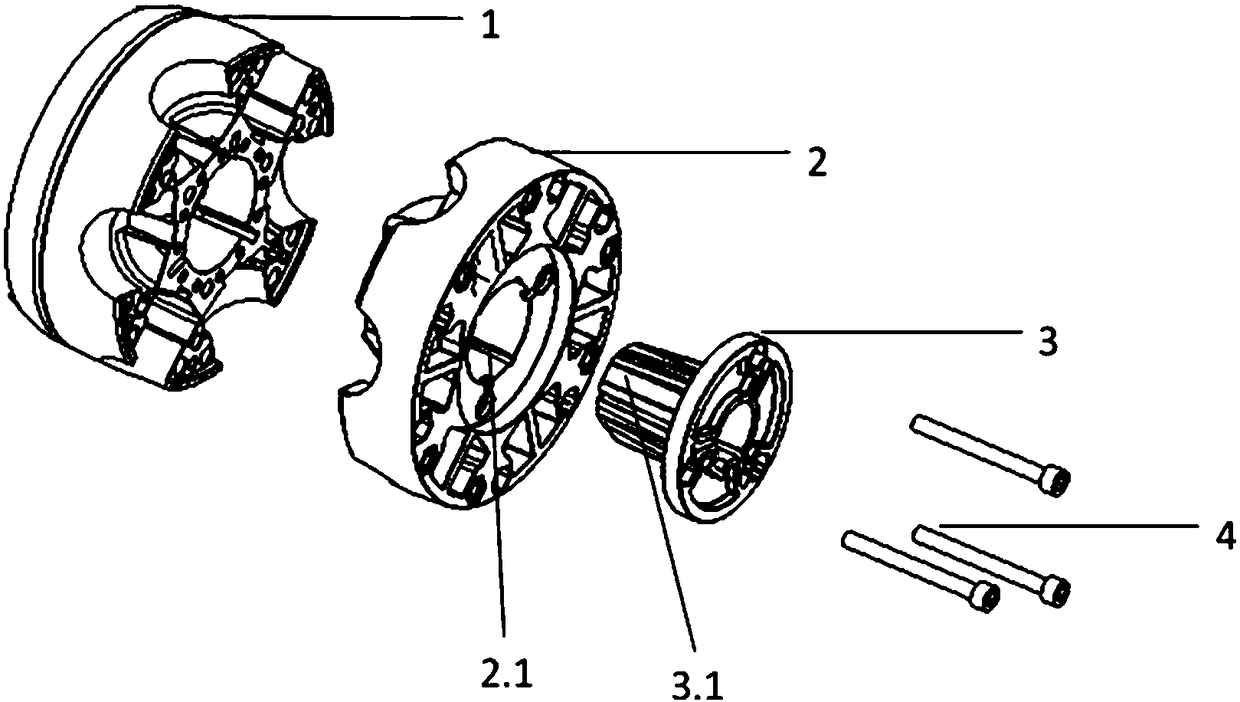

Image

Examples

Embodiment Construction

[0035] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0036] The wedge fit in the present invention refers to the close fit of two matching wedges.

[0037] Injection molding according to the present invention refers to a model with a certain shape, which is formed by injecting the colloid in the molten state into the mold cavity through pressure. The process principle is: melting the solid plastic according to a certain melting point, and using the pressure of the injection machine to A certain speed is injected into the mold, and the mold is cooled by water channels to solidify the plastic to obtain the same product as the designed cavity. It is mainly used for the molding of thermoplastics, and can also be used for the molding of thermosetting plastics.

[0038] Schematic diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com