Pulse plasma thruster based on Z-PINCH non-sparking plug

A pulsed plasma and thruster technology, applied in the direction of using plasma, thrust reverser, machine/engine, etc., can solve problems such as low propellant utilization rate, large volume of structural components, and reduced ignition voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

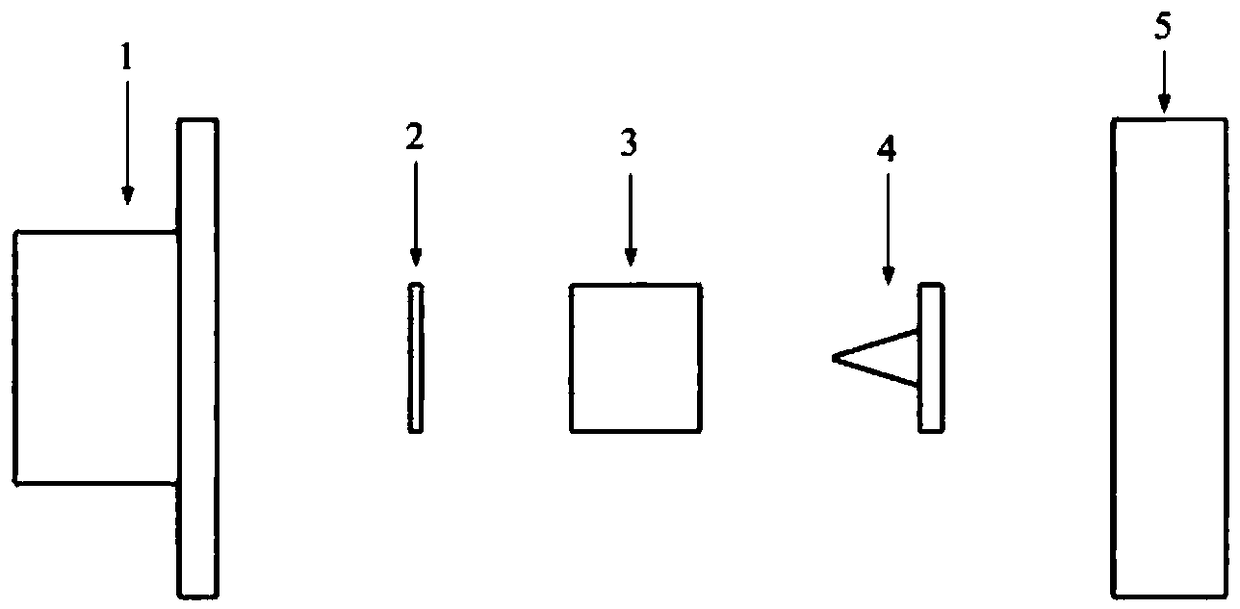

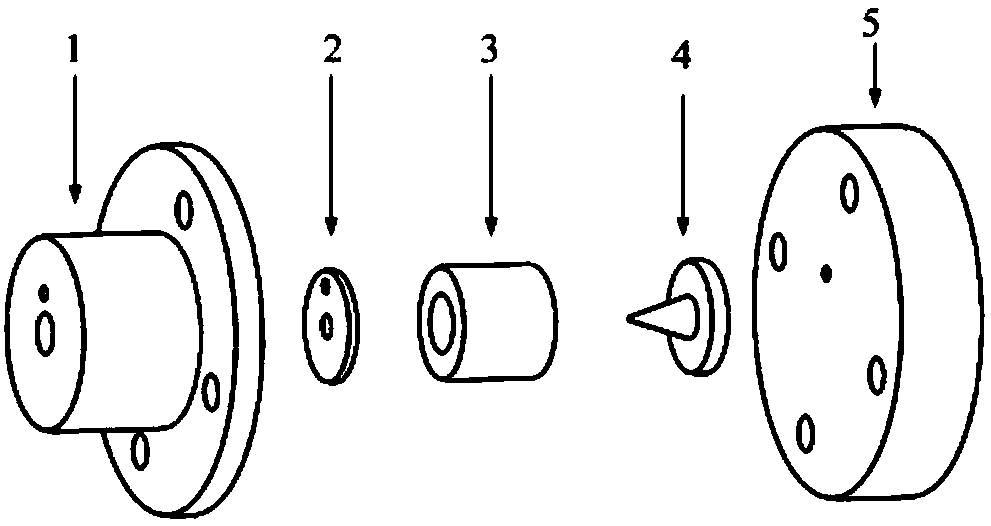

[0020] Such as figure 1 and figure 2 As shown, it is a new type of pulsed plasma propulsion device based on the Z-PINCH principle without spark plugs involved in this embodiment, including: an outer insulator 1, a cathode 2, a solid propellant 3, an anode 4 and The base 5, wherein: the circular hole on the top of the cathode 2 is used for connecting an external circuit. The circular small hole at the bottom of the anode 4 is used for connecting an external circuit.

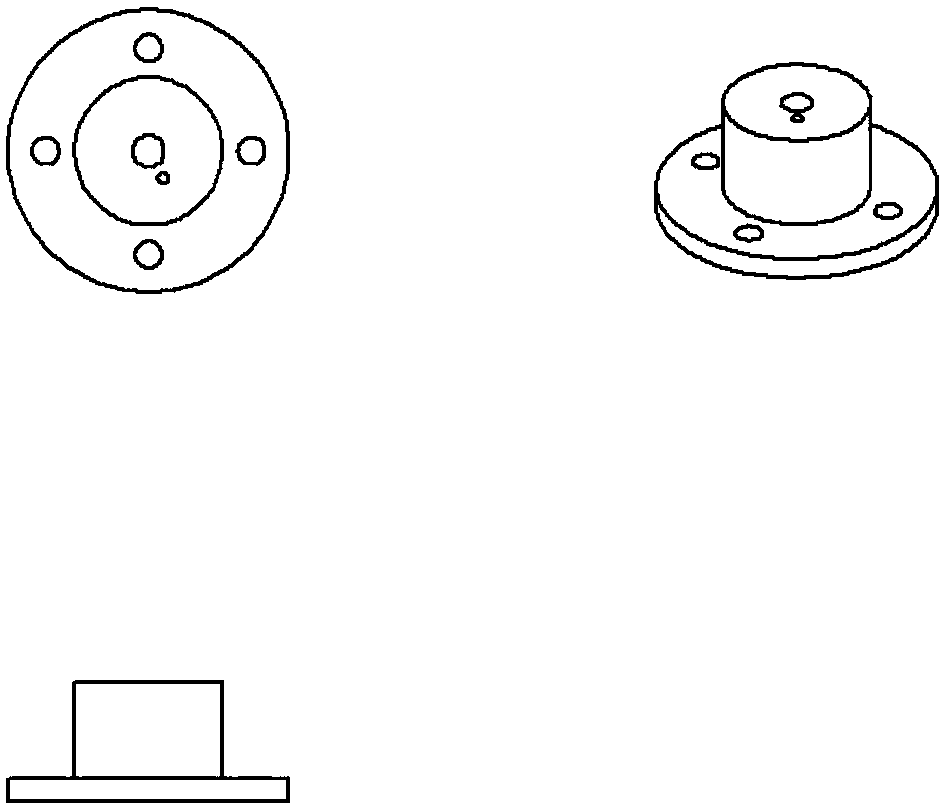

[0021] Such as image 3 , 7 As shown, the outer layer insulator 1 and the base 6 are both made of polycarbonate, which has flame retardancy, wear resistance and oxidation resistance.

[0022] Such as Figure 4 , 6 As shown, both the cathode 2 and the anode 4 are made of metallic copper, which has good electrical conductivity, high temperature resistance and high melting point. There is a small hole in the middle of the cathode 2, and the plasma generated after the solid propellant 3 is ablated is ejected f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com