Fuel filter assembly

A fuel filter and assembly technology, applied in the direction of machines/engines, liquid fuel feeders, fuel heat treatment devices, etc., can solve the problems of low integration, complicated filter assembly and installation, and difficult re-ignition, etc. problems, to improve assembly efficiency and facilitate the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

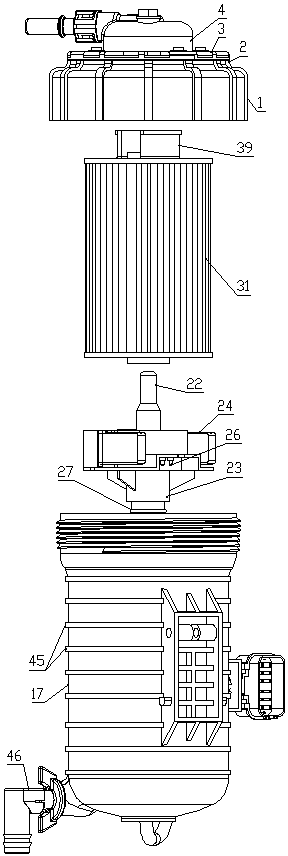

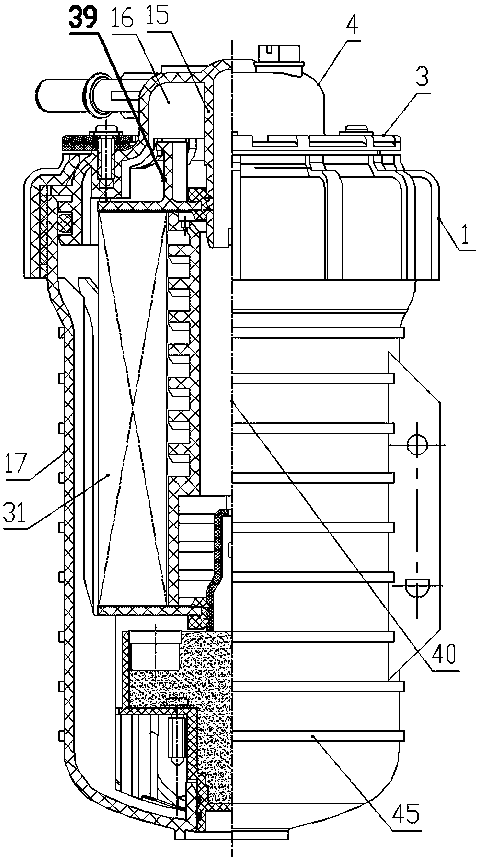

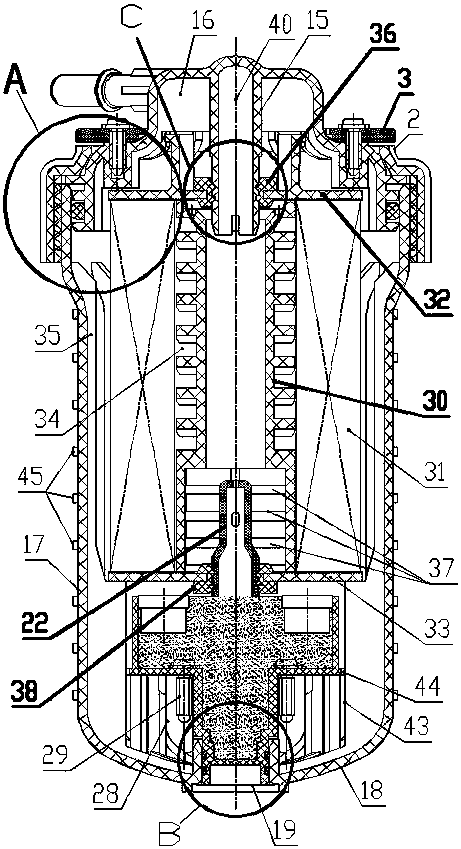

[0044] Such as Figure 1 to Figure 10 As shown, the fuel filter assembly of the present invention includes an upper housing assembly, a filter element assembly and a lower housing assembly;

[0045] The upper shell assembly includes a main body part, a cylindrical screw cap 1 and a gland part. The vertical centerline 40 of the three is the same straight line; The direction toward the centerline 40 is the outer direction;

[0046] There is a necking part 2 on the top of the screw cap 1; the gland part includes more than two gland ring segments 3, and all the gland ring segments 3 are spliced into a ring shape along the circumferential direction on the same horizontal plane;

[0047] The main part includes a cover tube 4, a shoulder 5 and a connecting tube 6 connected in sequence from top to bottom. The diameter of the connecting tube 6 is larger than that of the cover tube 4; the top of the cover tube 4 is fixedly connected with an oil inlet pipe 7 and an oil outlet pipe 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com