Tubing shifting conveying device and using method thereof

An oil pipe and mounting seat technology, which is applied to drilling pipes, casings, and earth-moving drilling and mining, etc., can solve the problems of not being able to be thrown to the top automatically, there are potential safety hazards, and manual handling is required. The effect of eliminating safety hazards and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

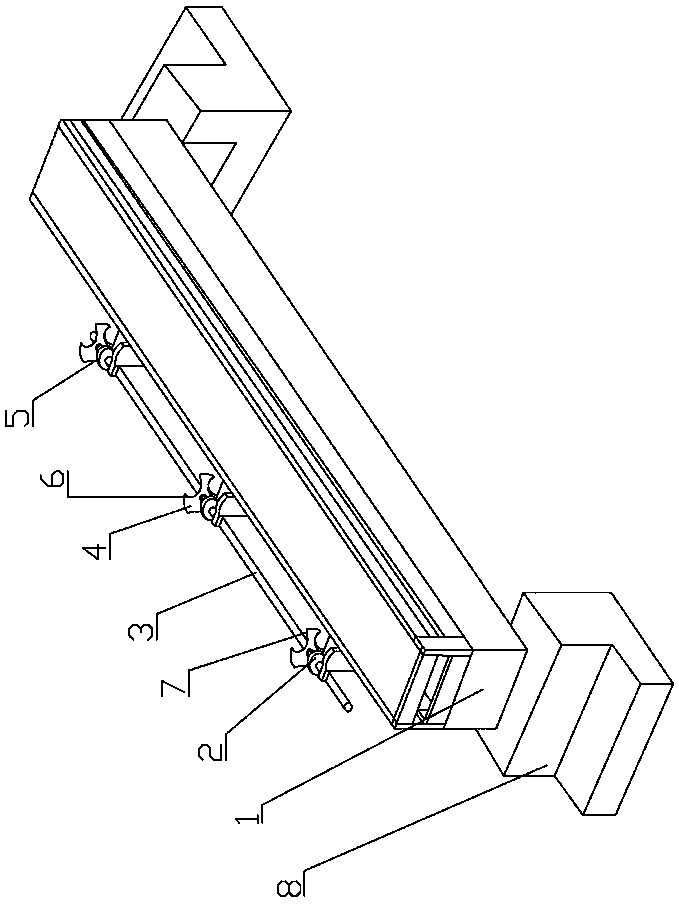

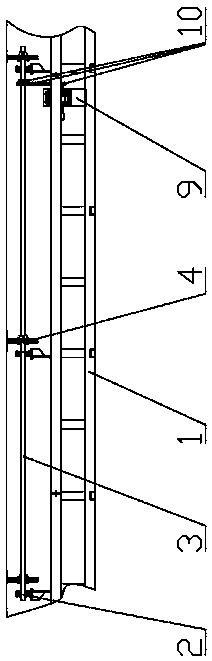

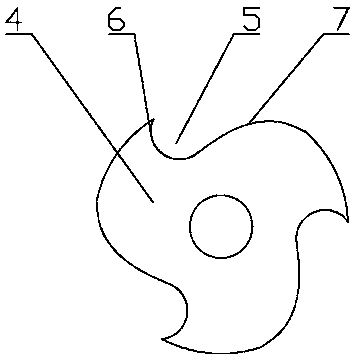

[0022] Embodiment one: as attached figure 1 , 2 , 3, the oil pipe dialing device includes a mounting seat 1, a bearing seat 2, a transmission shaft 3, a bearing body, a dial wheel 4 and a power drive device, and at least two bearing seats 2 are fixed on the mounting seat 1 at intervals along the front and rear , the transmission shaft 3 passes through the middle of the corresponding bearing housing 2 from front to back in sequence, and the front end of the transmission shaft 3 is located in front of the front bearing housing 2, the rear end of the transmission shaft 3 is located behind the rear bearing housing 2, and the transmission shaft 3 and the bearing seat 2 are installed with a bearing body; the outer side of the transmission shaft 3 is fixed with at least two dials 4 along the front and rear directions, and each dial 4 is evenly distributed along the circumference with at least one that can make the oil pipe be stuck from one side. Insert and flip the bayonet 5 that s...

Embodiment 2

[0029] Embodiment two: as attached figure 1 , 2 , 3, the method for using the tubing transfer device includes the following steps:

[0030] The first step is to place the tubing transfer device at the wellhead, make the left side of the tubing transfer device close to the existing tubing retention place, and make the left side of the tubing transfer device close to the existing tubing delivery place;

[0031]The second step is to transfer the tubing from the outlet of the tubing to the place where the tubing stays. In the initial state, a set of front and rear corresponding bayonets 5 are directed towards the outlet of the tubing, and the heights of the two match. When the dial wheel 4 rotates counterclockwise, the sending position should match the height of the place where the oil pipe is temporarily left. First, send the oil pipe on the place where the oil pipe is sent out to the corresponding bayonet 5, and then drive the power drive device 5 to drive the transmission shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com