Method for delaying crystallization of high fructose syrup

A fructose syrup and glucose syrup technology, which is applied in the production of fructose, sugar, glucose, etc., can solve the problems of easy crystallization and precipitation of fructose syrup, and achieve the effect of preventing crystallization and increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

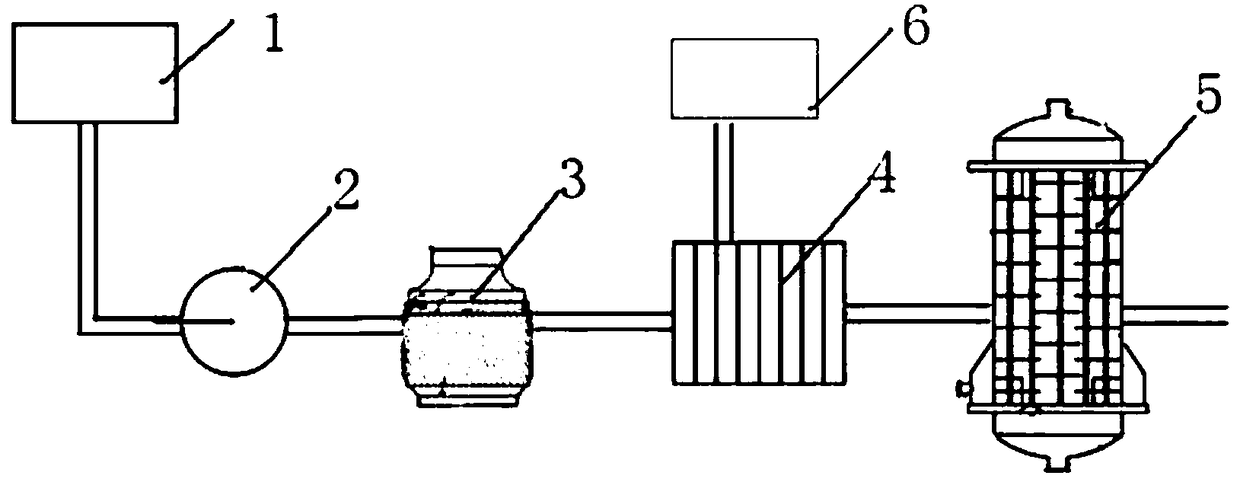

[0025] The system for delaying the crystallization of F42 fructose syrup includes: fructose syrup finished product tank 1, BNA045F03BA filter 3, plate heat exchanger 4, condenser 5 connected in sequence through pipelines; the plate heat exchanger is connected with a steam heating tank 6 , there is a steam heating pipeline between the steam heating tank 6 and the plate heat exchanger 4, the steam heating tank provides the steam for the plate heat exchanger 4, and the steam is transported to the plate heat exchanger 4 through the steam heating pipeline so that the plate heat exchanger The fructose syrup passed through in 4 is heated; between the fructose syrup finished product tank 1 and the filter 3, there is a pump 2 for conveying the material to the filter 3.

[0026] After the fructose syrup is produced, it is transported to the finished fructose syrup tank 1, and the finished fructose syrup is transported to the filter 3 by the pump 2 for filtration, and then the filtered fr...

Embodiment 2

[0092] In embodiment 2, adopt exactly the same equipment as embodiment 1, fructose syrup is processed;

[0093] After the fructose syrup is produced, it is transported to the finished fructose syrup tank 1, and the finished fructose syrup is transported to the filter 3 by the pump 2 for filtration, and then the filtered fructose syrup is heated to about 55°C by the plate heat exchanger 4 , and then the heated fructose syrup is condensed to 26° C. by the condenser 5, and finally the condensed fructose syrup is filled or dispensed under aseptic conditions.

[0094] The fructose syrup is delivered to the filter at a flow rate of 300-350L / min; after being heated to about 55°C, it is immediately sent to the condenser 5 for condensation.

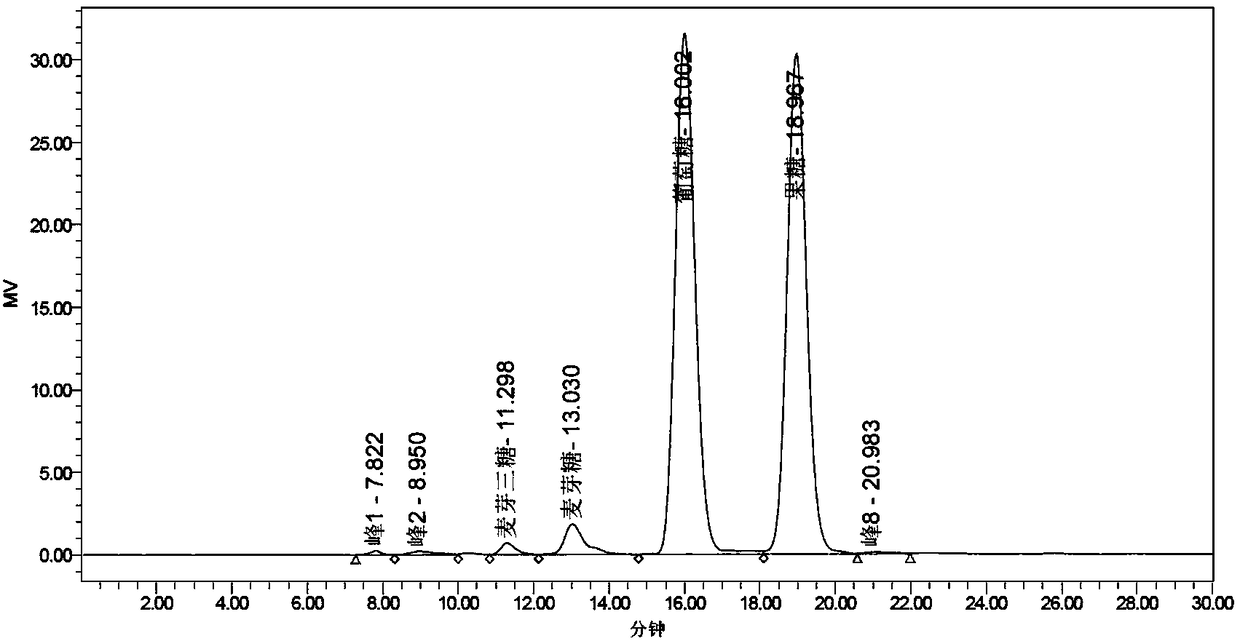

[0095] Get the high fructose syrup after the method and equipment treatment of embodiment 2, do following experiment:

[0096] Take different volumes of fructose syrup, numbered 1, 2, 3, 4;

[0097] Place them under the following conditions resp...

Embodiment 3

[0101] In embodiment 3, adopt exactly the same equipment as embodiment 1, fructose syrup is processed;

[0102] After the fructose syrup is produced, it is transported to the finished fructose syrup tank 1, and the finished fructose syrup is transported to the filter 3 by the pump 2 for filtration, and then the filtered fructose syrup is heated to about 50°C by the plate heat exchanger 4 , and then the heated fructose syrup is condensed to about 12°C by the condenser 5, and finally the condensed fructose syrup is filled or subpackaged under aseptic conditions.

[0103] The fructose syrup is delivered to the filter at a flow rate of 300-350L / min; after being heated to about 50°C, it is immediately sent to the condenser 5 for condensation.

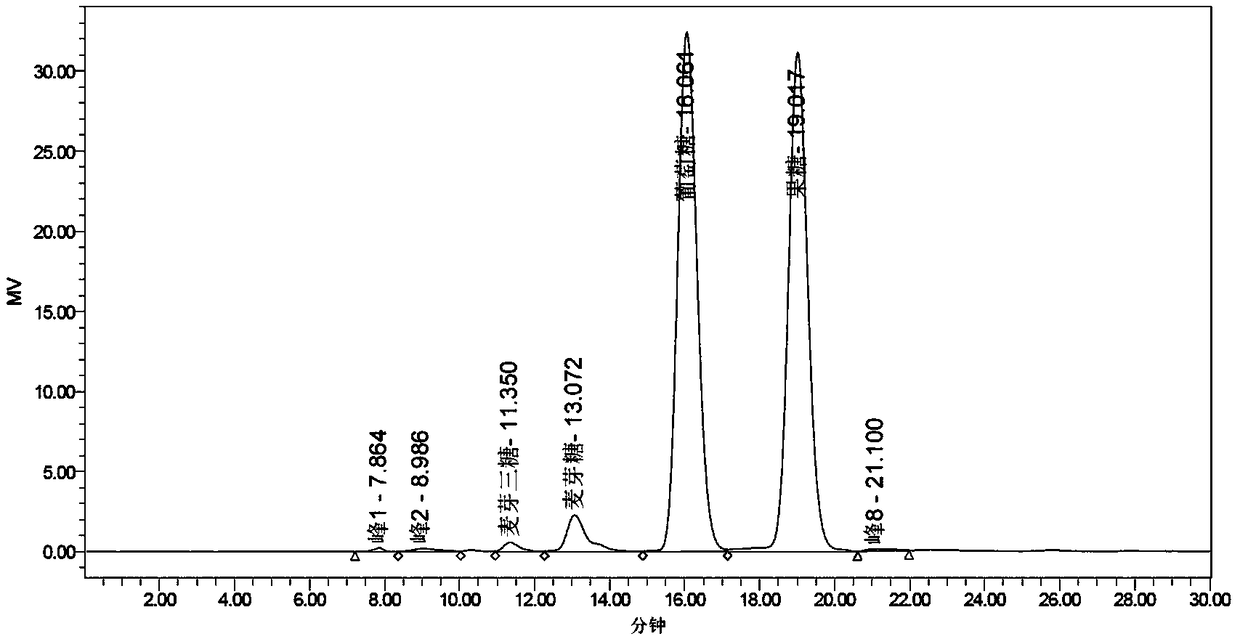

[0104] Get the high fructose syrup after the method and equipment treatment of embodiment 3, do following experiment:

[0105] Take different volumes of fructose syrup, numbered 1, 2, 3, 4;

[0106] Place them under the following condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com