Plastic connecting device and method of non iso-wall thickness metal tubular product

A technology of metal pipes with non-uniform wall thickness, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc. It can solve the problems of high requirements for equipment and tooling, not suitable for mass production, and difficult pipe connection, etc., to achieve joint Strong quality, fast and high-quality connection, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

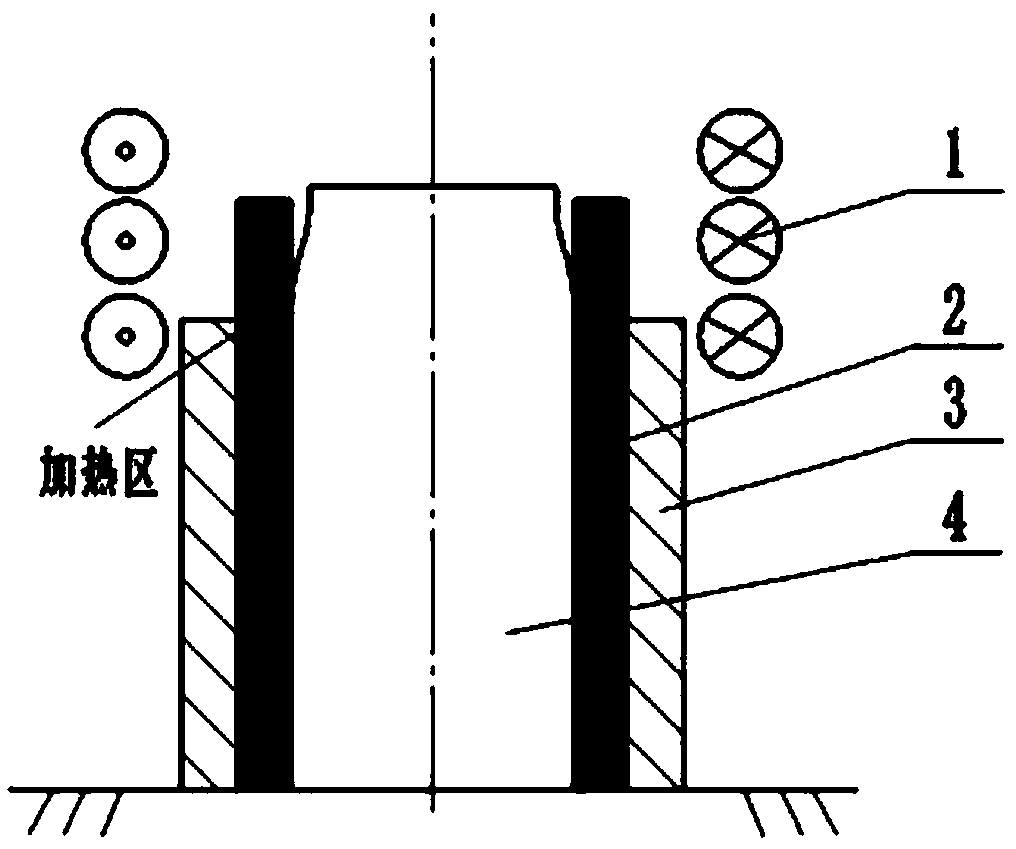

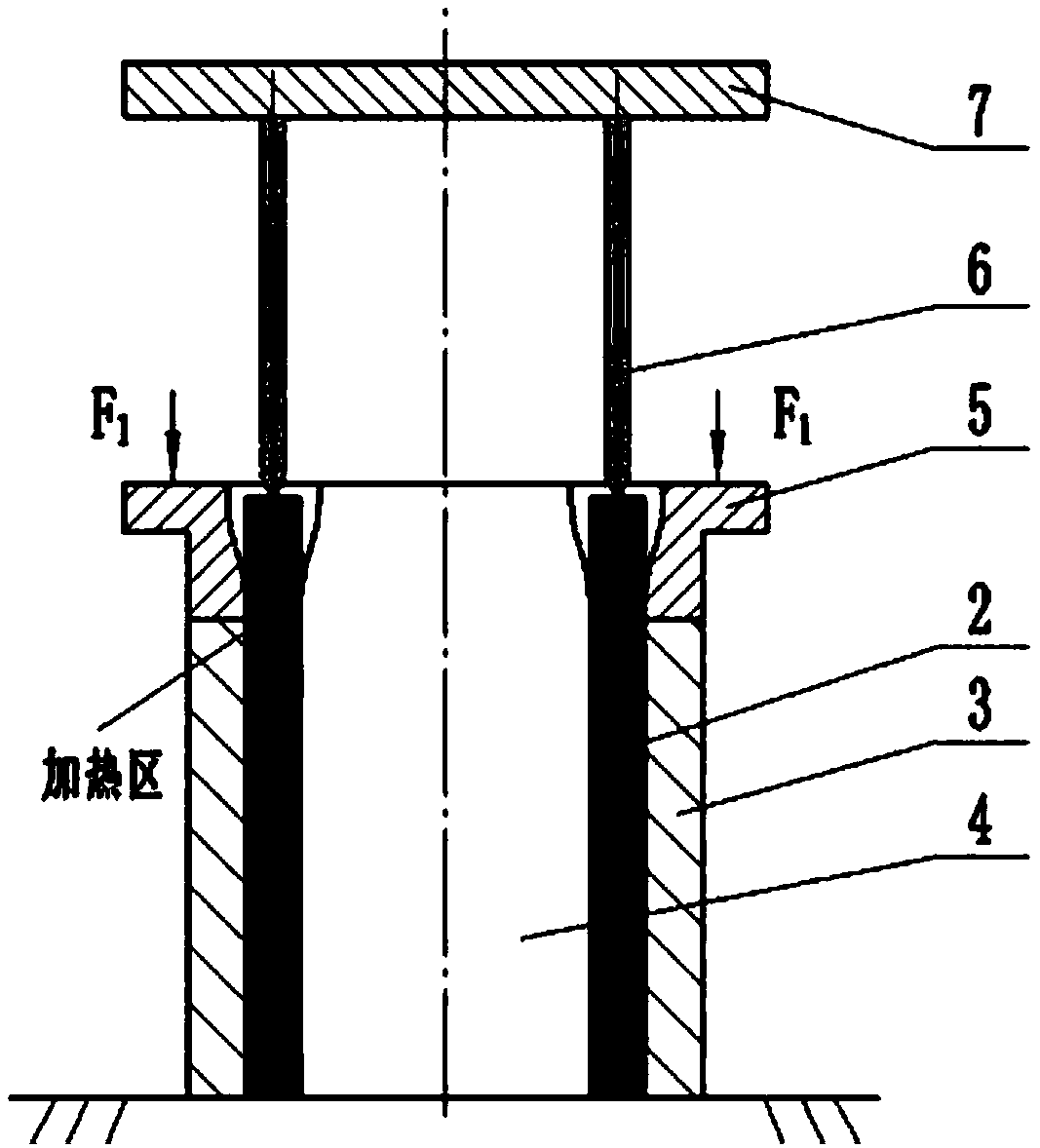

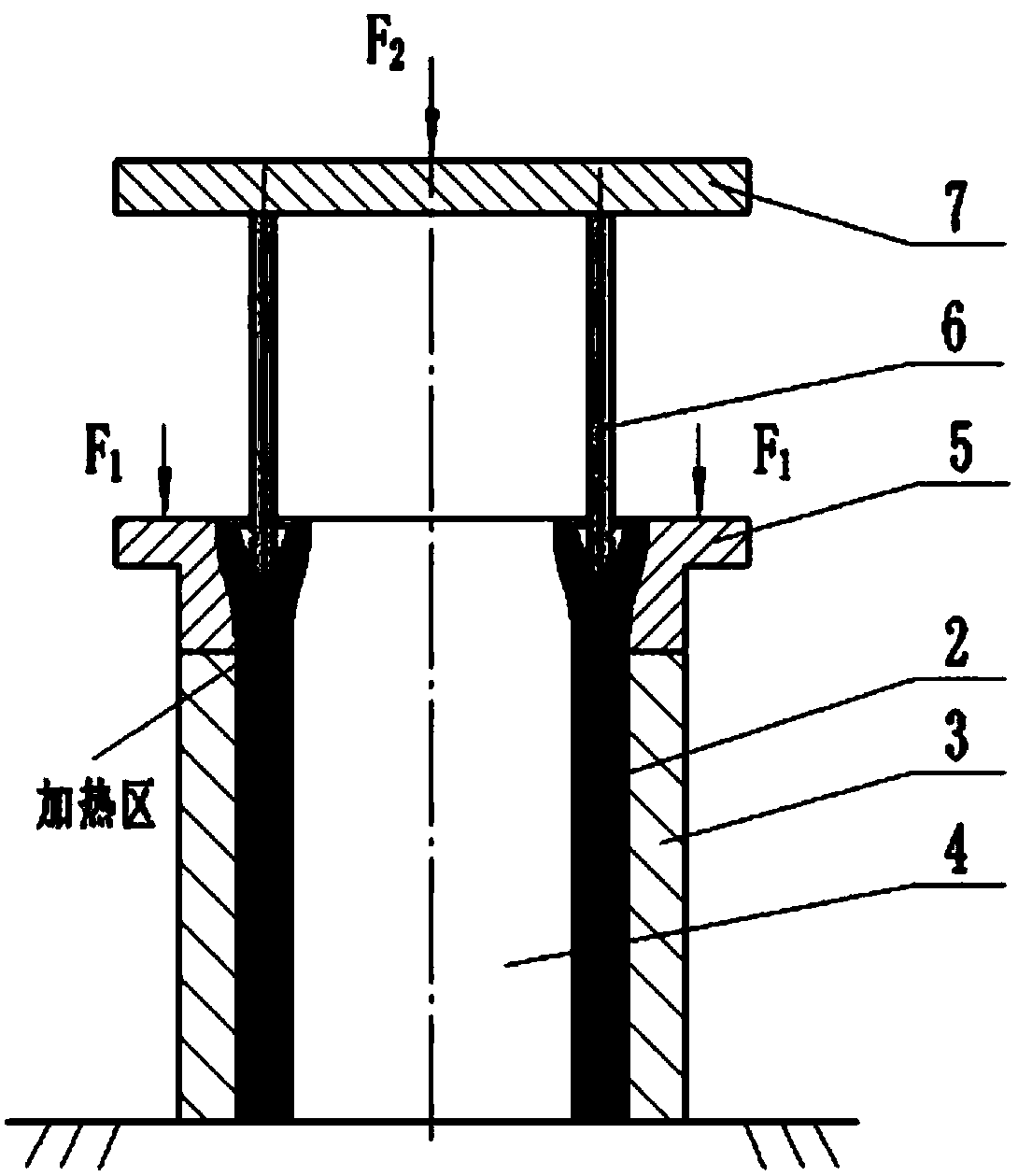

[0032] Such as figure 1 with figure 2 As shown, a plastic connection device for metal pipes with unequal wall thickness includes an induction coil 1, an upper die 7, a forming outer die 5, a fixed lower die 3 and a mandrel 4;

[0033] The fixed lower mold 3 is cylindrical, the mandrel 4 and the fixed lower mold 3 are coaxially arranged, the first wall thickness tube 2 is placed between the fixed lower mold 3 and the mandrel 4, and the inside of the first wall thickness tube 2 The surface is in contact with the mandrel 4, the outer surface is in contact with the inner surface of the fixed lower die 3, and the lower end of the second wall thickness tube 6 is a sharp angle;

[0034] When heating, the induction coil 1 is placed in the local heating zone at the upper end of the first wall thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com