Paint charging and discharging system used for vamp painting

A technology for shoe uppers and paint supply, which is applied in the direction of spraying devices and liquid spraying devices, which can solve the problems of not getting paint from paint spraying containers, excessive paint discharge, etc., and achieve the effects of smooth discharge, simple manufacture, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

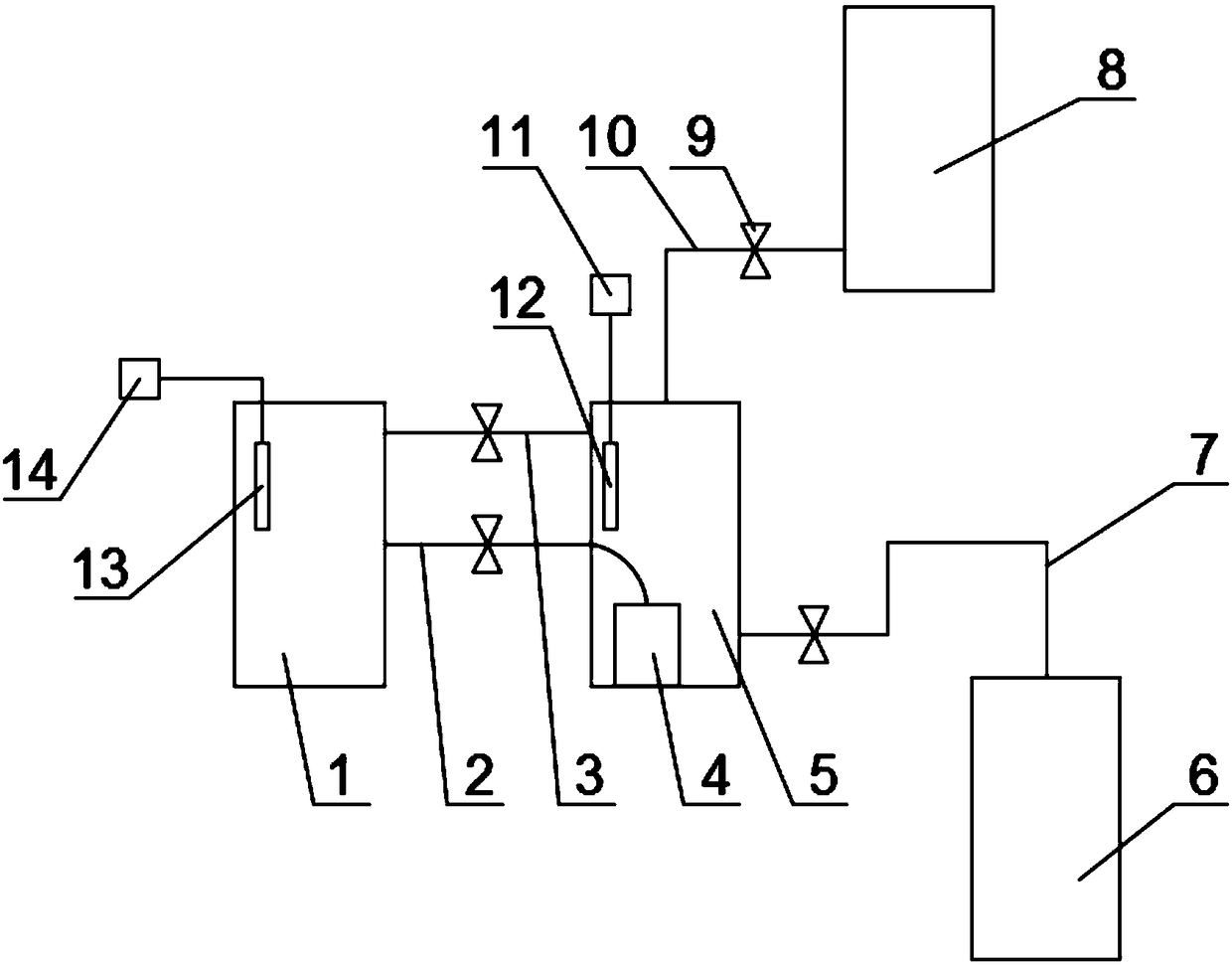

[0014] Such as figure 1 As shown, the paint-discharging system for shoe upper painting includes a paint spraying container 1, a paint supply container 5, a paint receiving container 6 and a paint injection container 8, wherein a paint inlet pipeline 2 is arranged between the paint spraying container 1 and the paint supply container 5 And the paint return pipeline 3, the pump 4 is arranged in the paint supply container 5, the paint inlet pipeline 2 and the pump 4 are connected by pipelines, the paint discharge pipeline 7 is arranged between the paint receiving container 6 and the paint supply container 5, and the paint discharge pipeline 7 The highest point of the pipeline is higher than the top of the pump 4 in the paint supply container 5, a paint injection pipeline 10 is arranged between the paint injection container 8 and the paint supply container 5, the paint inlet pipeline 2, the paint return pipeline 3, and the paint injection pipeline 10 A cut-off valve 9 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com