Cooling and white smoke eliminating device and method for circulating slurry for desulfurizing tower of thermal power plant

A technology for desulfurization towers and thermal power plants. It is applied in the fields of flue gas purification and white smoke elimination. It can solve the problems of insufficient energy utilization, easy corrosion and leakage of heat exchangers, acid dew point corrosion of equipment, etc., and achieves low cost of transformation and operation. Short cycle, the effect of eliminating white smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

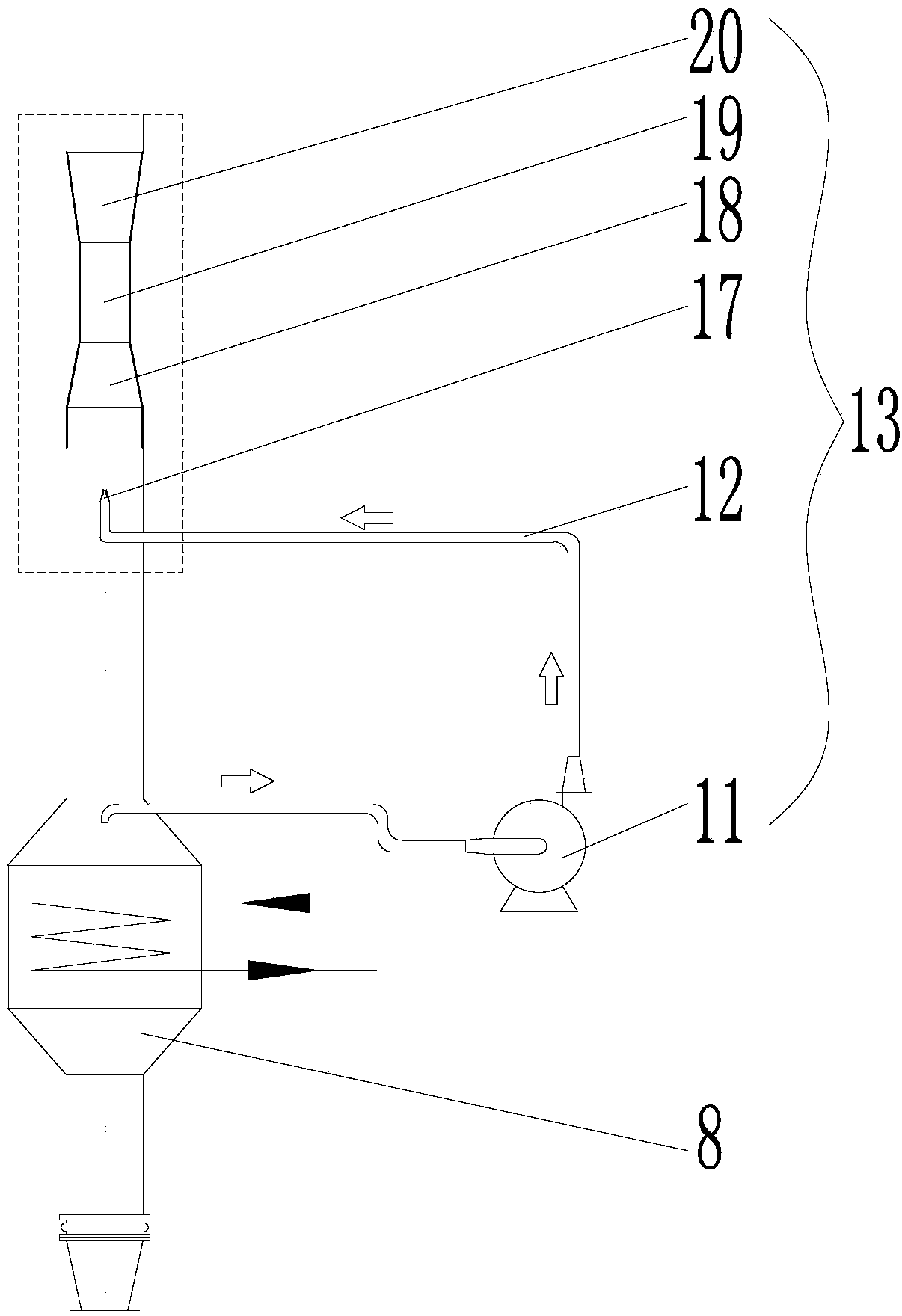

[0040] Embodiment 1 of the present invention: as figure 1As shown, a device for cooling and eliminating white smoke of the desulfurization tower circulating slurry in a thermal power plant includes a desulfurization tower 4 connected to the flue gas inlet, an electric butterfly valve 5 connected to the desulfurization tower 4, and an electric butterfly valve connected to the electric butterfly valve 5. The slurry circulation pump inlet pipe 6, the slurry circulation pump 7 connected to the slurry circulation pump inlet pipe 6, the slurry cooler 8 connected to the slurry circulation pump 7, the slurry injection booster connected to the slurry cooler 8 Device 13, the outlet pipe 14 of the slurry circulation pump connected to the slurry injection booster device 13, the top spray layer 2 in the desulfurization tower 4 connected to the outlet pipe 14 of the slurry circulation pump, and the flue gas passes through the top spray layer 2 And the demister 15 enters the chimney through ...

Embodiment 2

[0041] Embodiment 2: as figure 1 As shown, a device for cooling and eliminating white smoke by circulating slurry in a desulfurization tower of a thermal power plant includes a desulfurization tower 4, an electric butterfly valve 5, a slurry circulation pump inlet pipe 6, a slurry circulation pump 7, a slurry cooler 8, and a slurry injection pressure booster Device 13 and slurry circulation pump outlet pipe 14. The top of the desulfurization tower 4 is provided with a desulfurization tower outlet 1, the middle part of the side of the desulfurization tower 4 is provided with a desulfurization tower inlet 3, and the top floor spray layer 2 and a demister 15 are arranged in the described desulfurization tower 4, wherein the top floor A desulfurization tower inlet 3 is provided below the spray layer 2 , a demister 15 is provided above the top spray layer 2 , and a desulfurization tower outlet 1 is provided above the demister 15 . The bottom side of the desulfurization tower 4 is ...

Embodiment 3

[0042] Embodiment 3: as figure 1 As shown, a device for cooling and eliminating white smoke by circulating slurry in a desulfurization tower of a thermal power plant includes a desulfurization tower 4, an electric butterfly valve 5, a slurry circulation pump inlet pipe 6, a slurry circulation pump 7, a slurry cooler 8, and a slurry injection pressure booster Device 13 and slurry circulation pump outlet pipe 14. The top of the desulfurization tower 4 is provided with a desulfurization tower outlet 1, the middle part of the side of the desulfurization tower 4 is provided with a desulfurization tower inlet 3, and the top floor spray layer 2 and a demister 15 are arranged in the described desulfurization tower 4, wherein the top floor A desulfurization tower inlet 3 is provided below the spray layer 2 , a demister 15 is provided above the top spray layer 2 , and a desulfurization tower outlet 1 is provided above the demister 15 . The bottom side of the desulfurization tower 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com