Inspection smoke machine

A smoke generating device technology, applied in measuring devices, detecting the appearance of fluid at the leak point, testing the engine, etc., can solve the problems of damaging the engine system, inefficiency, and expensive smoke machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

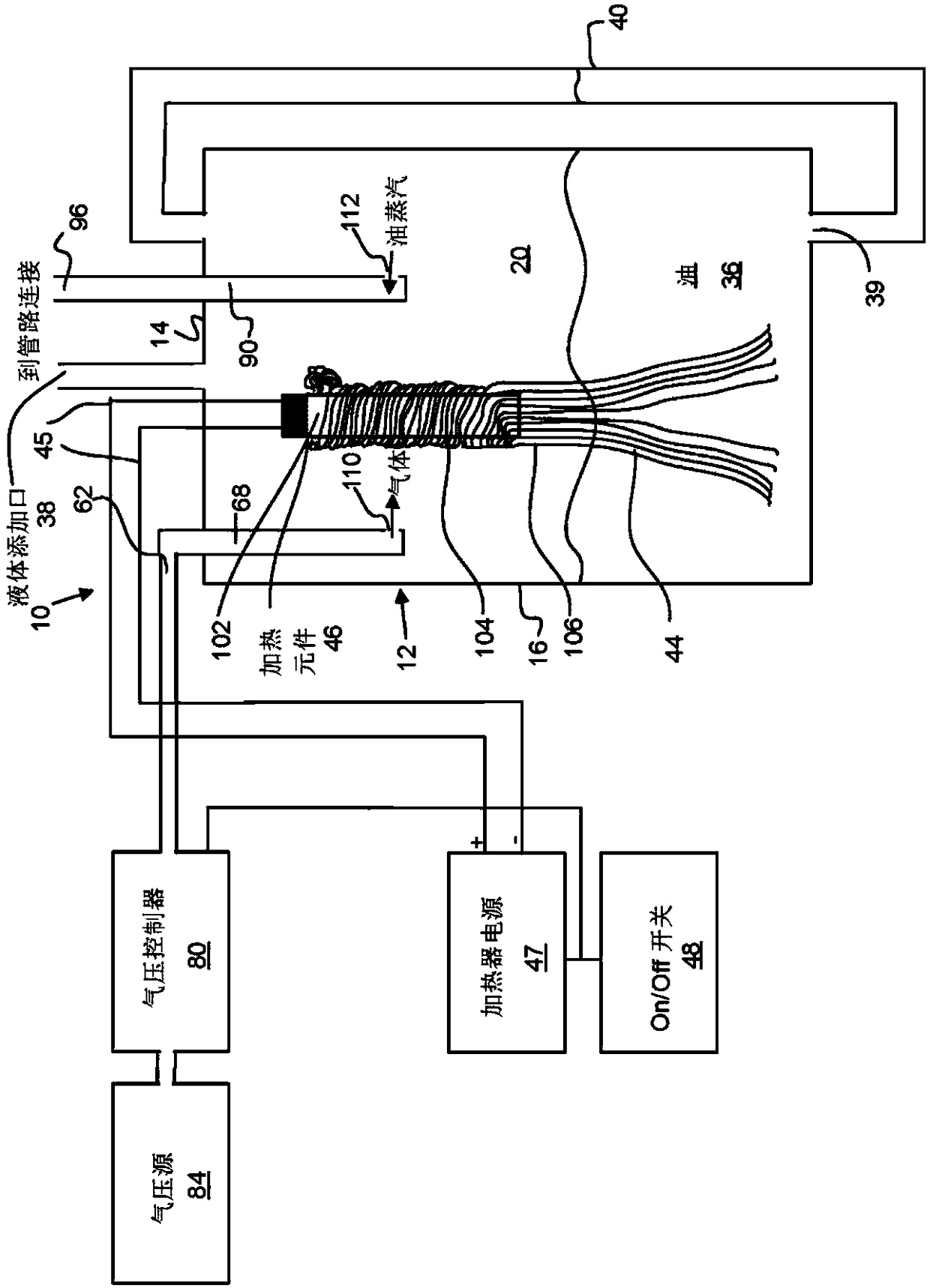

[0024] The invention relates to a variable pressure fog machine, characterized by different pressure modes of operation. In the first pressure mode of operation, the fogger is operable to generate steam at a first predetermined test pressure, and in the second pressure mode of operation, the fogger is operable to generate steam at a second predetermined test pressure. The variable pressure fogger has a pressure controller that switches the fogger between the first and second pressure modes of operation in response to activation of an operating mode selector control.

[0025] The present invention also relates to an improved fog machine featuring a novel wick and heater arrangement. The heater may be a ceramic heater with increased durability. The wick easily wraps around the heater and is easily removed to replace the wick or heater if desired.

[0026] Note that while the term "smoke" generally refers to vapors and particulates that are byproducts of incomplete combustion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com