Oxazoline-based adhesive formulations

A formulation and adhesive technology, applied in the direction of adhesives, adhesive types, protein adhesives, etc., can solve the problem of increased adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0039] The present disclosure is further illustrated by the following examples, which should not be construed in any way as limiting its scope. On the contrary, it is to be clearly understood that various other embodiments, modifications and equivalents thereof, which may occur to those skilled in the art after reading the description herein, may be employed without departing from the scope of the appended claims .

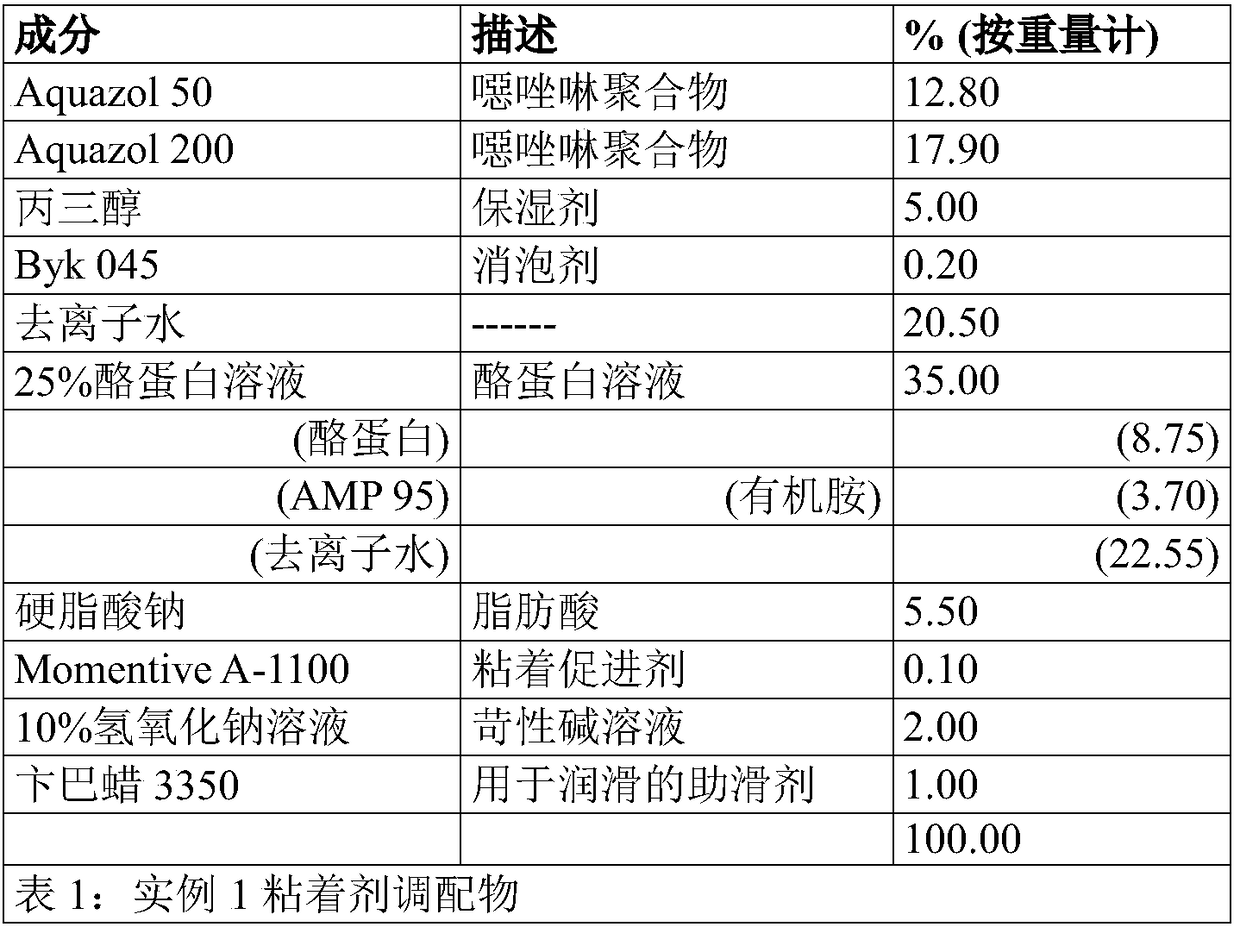

example 1

[0041] A first exemplary formulation was prepared that included an oxazoline polymer and casein to provide the desired adhesive properties. The formulation compositions are shown in Table 1 below.

[0042]

[0043] This formulation was prepared by the following exemplary process: (i) blending Aquazol 50 and Aquazol 200 together, adding deionized water and then storing the resulting premix at elevated temperature (e.g., 80°C) for 6-8 hours, followed by Mix gently until the mixture is essentially homogeneous; (ii) add glycerol and antifoam and mix gently; (iii) separately, by combining organic amine and water and add casein, then mix the solution Prepare the casein solution until it is a homogeneous solution; (iv) add the casein solution to the batch and mix the solution; (v) add sodium stearate and Bienba wax powder together and add to the batch; (vi) Maintain heat at 75-80°C and mix at low spread for about 15-30 minutes or until it is homogeneous; (vii) add silane coupling...

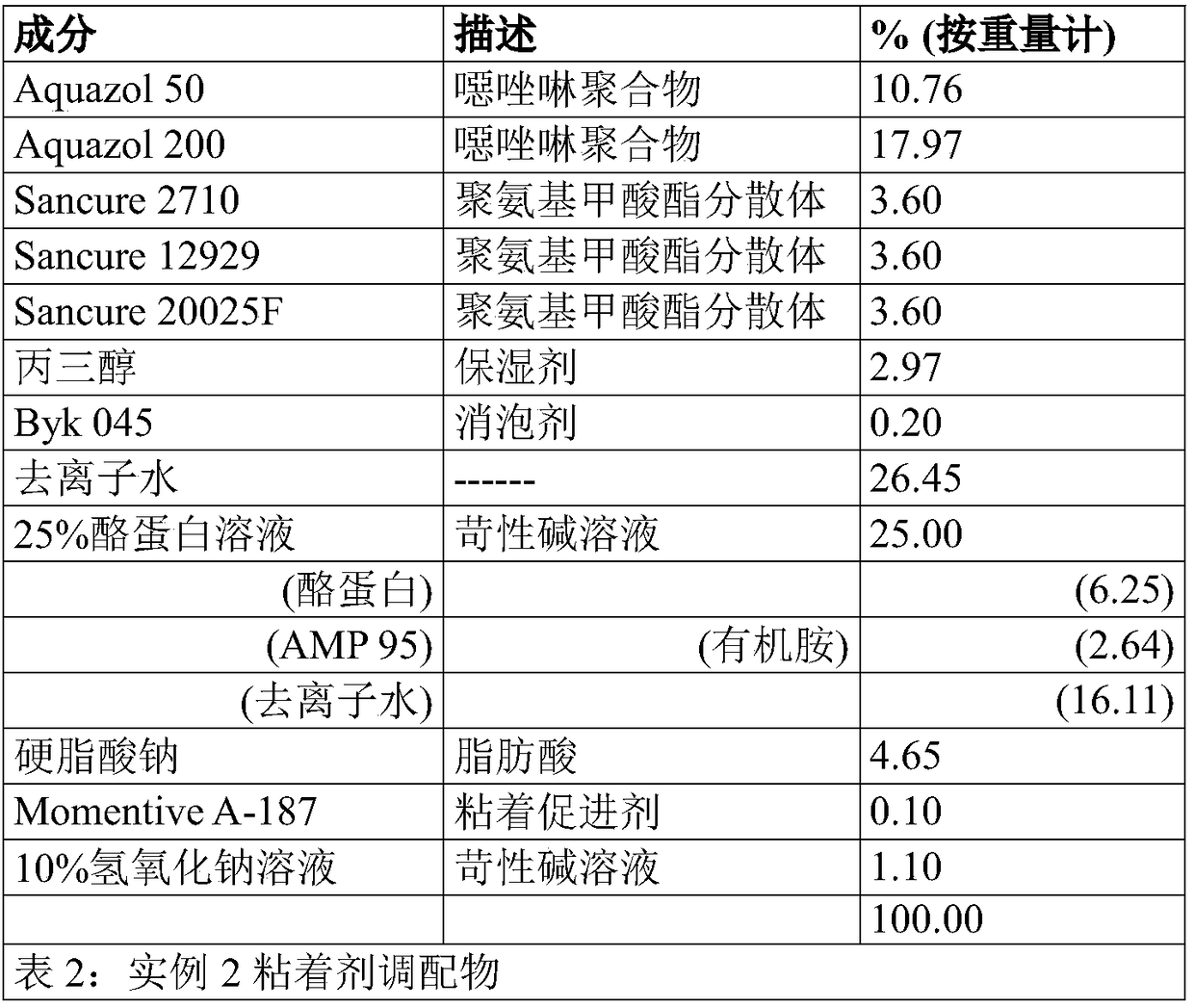

example 2

[0046] A second exemplary formulation was prepared that included a polyurethane dispersion (PUD) in the formulation for further enhanced adhesion to various surfaces. The formulation compositions are shown in Table 2 below.

[0047]

[0048] This formulation was prepared by the following exemplary process: (i) blending Aquazol 50 and Aquazol 200 together, adding deionized water and then storing the resulting premix at elevated temperature (e.g., 80°C) for 6-8 hours, followed by Mix gently until the mixture is essentially homogeneous; (ii) add glycerol and antifoam and mix gently; (iii) separately, by combining organic amine and water and add casein, then mix the solution Prepare the casein solution until it is a homogeneous solution; (iv) add the polyurethane dispersion to the batch and continue mixing; (v) add the casein solution to the batch and mix the solution; (vi) add the Add sodium stearate to batch; (vii) maintain heat at about 75-80°C and mix on low spread for abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com