Inkjet recording apparatus and air bubble removal method

An inkjet recording and recording head technology, applied in the direction of printing, can solve the problems of poor ink ejection and inability to apply pressure to the ink, and achieve the effect of rapid removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

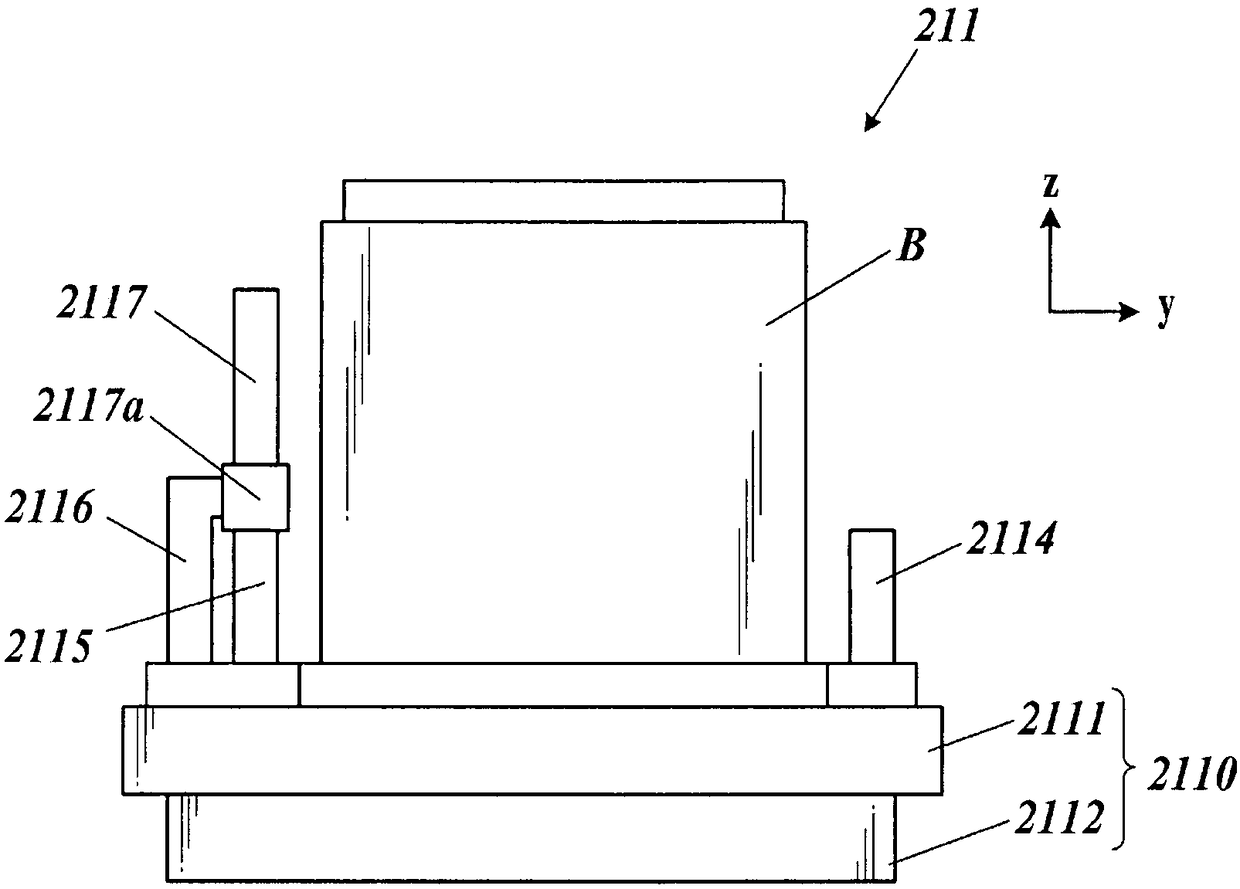

[0156] An inkjet head in which a communication port was provided on the lower surface of the common ink chamber and a head chip provided with individual flow paths corresponding to the communication ports were joined to the inkjet head.

[0157] In the center of the height direction of the common ink chamber, a filter is installed horizontally, and the flow path section of the upper ink chamber of the rectangular parallelepiped shape is set to 36mm 2 , And set the flow path section of the lower ink chamber of the rectangular parallelepiped shape to 28mm 2 . At both ends of the upper surface of the upper ink chamber, a cylindrical inflow passage and a discharge passage with a diameter of 2.8 mm are provided, and the upper surface of the end opposite to the inflow passage in the lower ink chamber is provided with the same size 的discharge path. In the discharge passage provided in the upper ink chamber, a narrow member with a length of 14 mm having a cylindrical hollow structure with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com