Radial rotation error prediction method for static air pressure main shaft

An aerostatic spindle and rotation error technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the influence of spindle vibration and the impact on bearing dynamic characteristics, and achieve the effect of optimal design and error control

Active Publication Date: 2018-07-17

BEIJING UNIV OF TECH

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

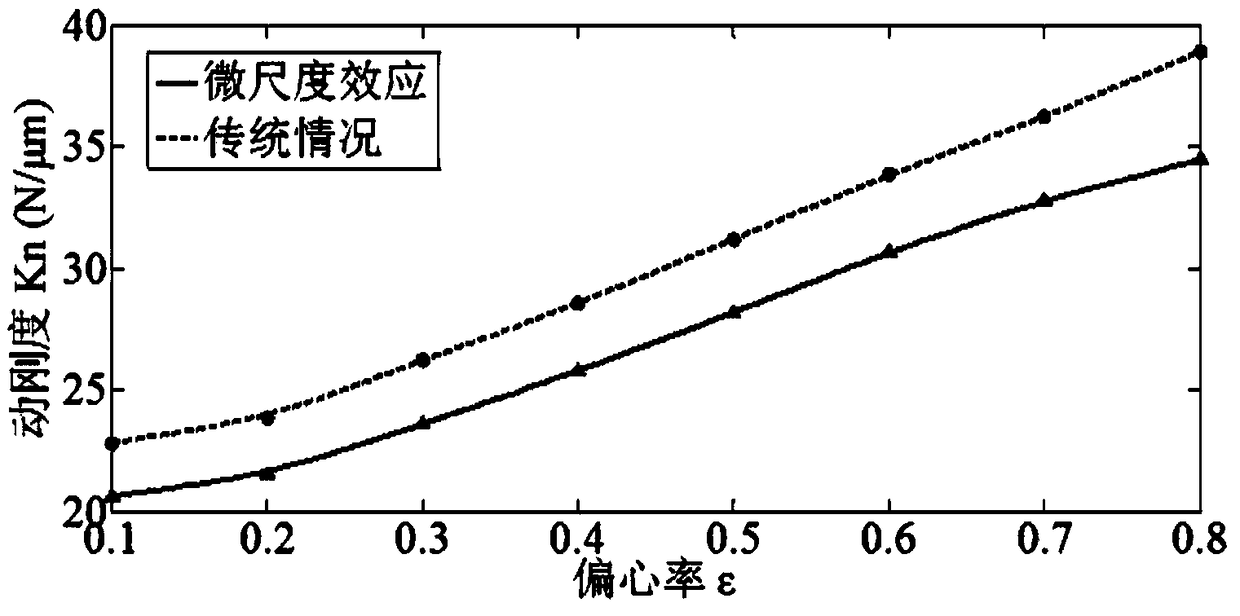

Due to the compressibility of the air film in the aerostatic bearing, the fluctuation of the air film will be directly reflected in the vibration of the spindle; at the same time, because the bearing gap of the aerostatic bearing is at the micron level, the gas flow inside it belongs to the micro-scale flow. It will show micro-scale effects that traditional flow does not have, such as: rarefaction effect, speed slip, etc. These micro-scale effects will affect the dynamic characteristics of the bearing, thereby affecting the vibration of the main shaft

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

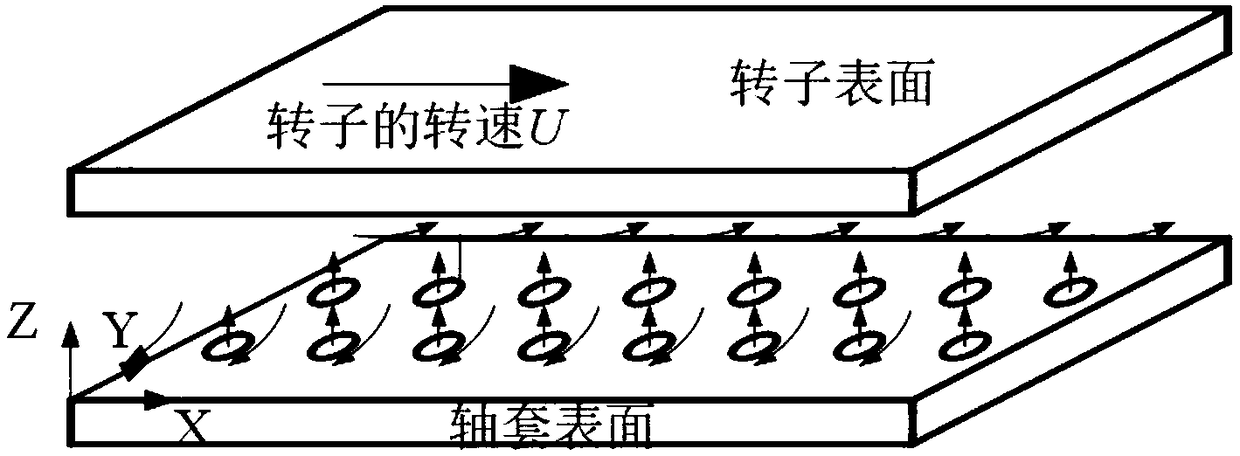

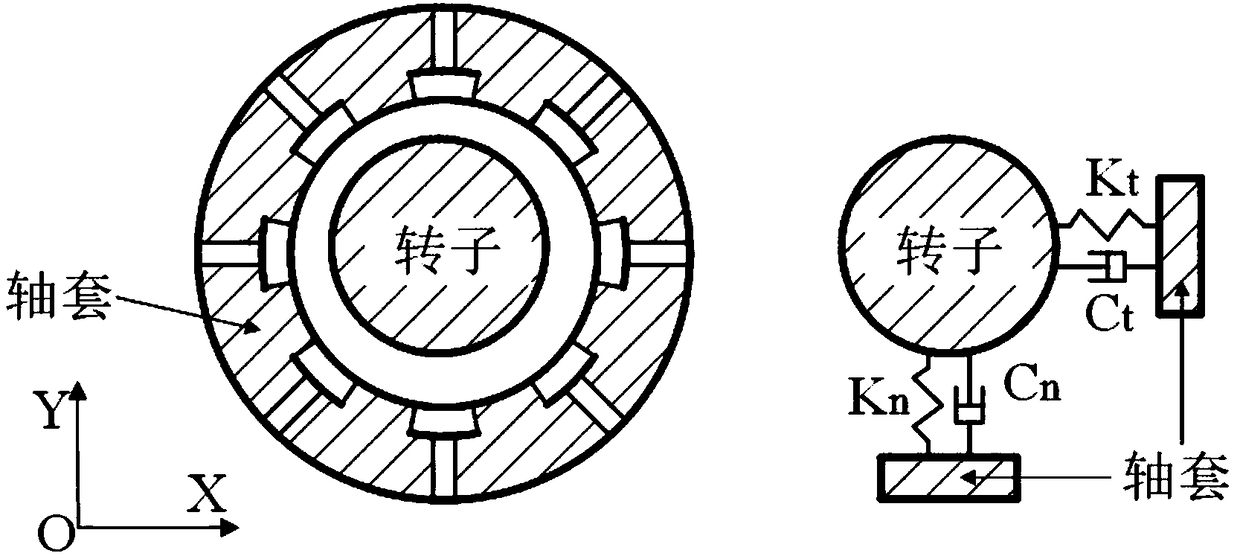

Provided is a radial rotation error prediction method for a static air pressure main shaft. The method conducts prediction in consideration of micro-scale effects of air film flow in a static air pressure bearing and nonlinear dynamic characteristics. According to the structure and a principle of the static air pressure bearing, flow factors embodying the micro-scale effects are introduced to establish a mathematical model of the air film flow of the static air pressure radial bearing under micro-scale; an air film is transformed into a spring damping system with two freedom degrees perpendicular to each other, the flow model is calculated, and nonlinear dynamic stiffness and damping coefficients are assigned to the spring damping system under the micro-scale; according to the structure and working principle of the static air pressure main shaft, a bearing-rotor system model composed of the air film and a rotor is established; based on the characteristics of main shaft vibration, a mathematical model of dynamic vibration of the bearing-rotor system is established; various vibration errors of the static air pressure main shaft are obtained, and total radial rotation errors of the main shaft are obtained by integrating the various errors.

Description

technical field The invention relates to a rotation error prediction method, which is suitable for the prediction and analysis of the rotation error of an air static pressure spindle under different working conditions, and can realize the time domain and frequency domain signal prediction of the vibration signal of the air static pressure spindle. Background technique Aerostatic spindle is an important processing equipment in the process of precision and ultra-precision machining, and its motion error directly affects the surface quality, shape accuracy and roughness of the processed parts. Therefore, it is very important to predict and analyze the rotation error of the aerostatic spindle, which is of great significance to the optimal design and error monitoring and control of the aerostatic spindle. During the actual operation, the aerostatic spindle will produce forced vibration, self-excited vibration and yaw vibration due to the action of external force, self-gravity an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F17/50

CPCG06F30/20

Inventor 陈东菊韩继弘潘日范晋伟

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com