Fermentation method of gibberellic acid

A fermentation method and gibberellic acid technology, applied in the field of fermentation, can solve problems to be improved, and achieve the effects of ensuring synthesis and metabolism, fast and stable fermentation, and increasing acid production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1.1 Will GA 3 The strain freezing tube was directly connected to the shake flask, and the inoculum amount was 0.8% of the volume of the culture medium in the shake flask. The medium formula in the shake flask was shown in Table 1. The fermentation temperature was 29±0.2°C, and the shake flask was cultivated for about 68 hours to obtain a suspension.

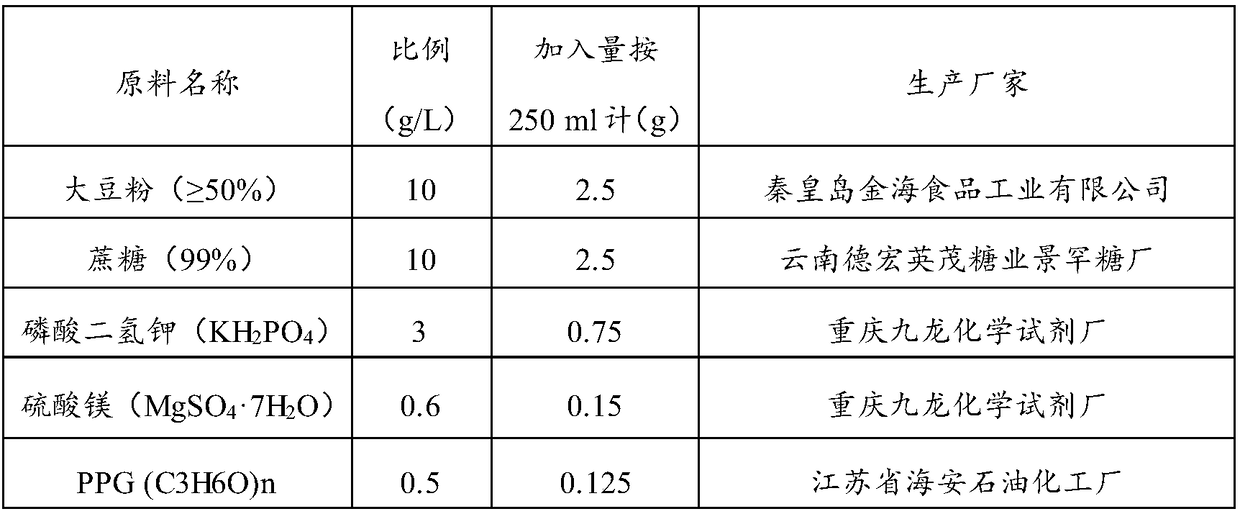

[0046] Table 1 shake flask culture medium formula

[0047]

[0048] 1.2 Inoculate the suspension into the primary seed tank, the inoculation amount is 0.016% of the volume of the culture solution, and the medium formula of the primary seed tank is shown in Table 2.

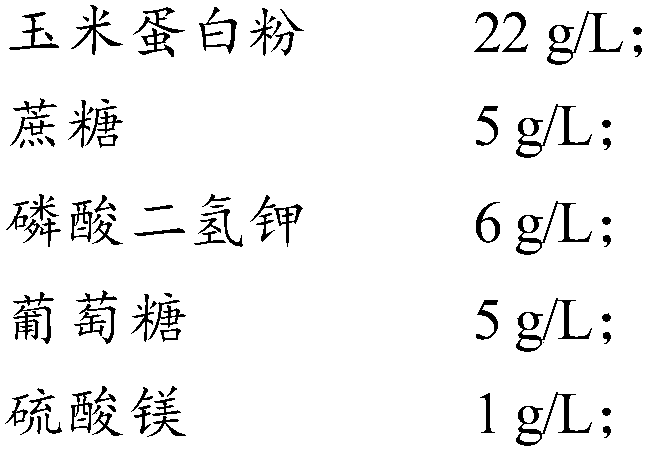

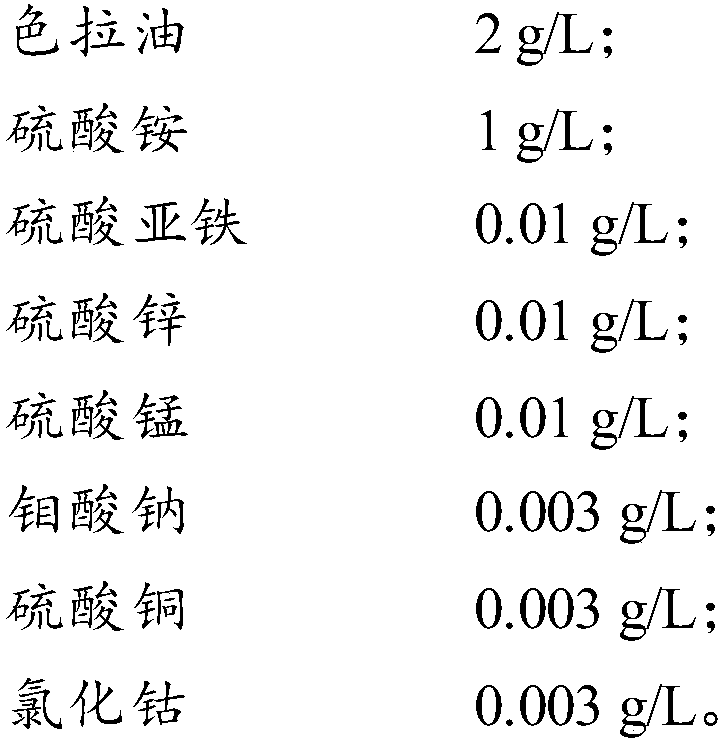

[0049] Table 2 Primary seed tank culture medium formula

[0050]

[0051]

[0052] Fermentation volume: constant volume 1.3t, the volume after digestion is calculated as 1.5t (add sulfuric acid before sterilization to adjust the pH to 5.1).

[0053] Fermentation temperature: 29±0.2°C.

[0054] Operating tank pressure: 0.035MPa.

[0055] Air flow: ...

Embodiment 2

[0084] The medium formulation and culture conditions are the same as in Example 1.

[0085] Feeding control: Dissolved oxygen rebounds by 20%, automatic feeding of glucose (45%) solution is started, and the dissolved oxygen control point is 20% to 30%.

[0086] The fermentation broth obtained in Example 2 was detected, and the results obtained are shown in Table 8 and Table 9.

[0087] Table 8 Fermentation broth detection data

[0088]

[0089]

[0090] Table 9 Wet weight of fermentation broth

[0091]

Embodiment 3

[0093] The medium formulation and culture conditions are the same as in Example 1.

[0094] Feeding control: Dissolved oxygen rebounds by 20%, automatic flow of salad oil is turned on, and the dissolved oxygen control point is 20% to 30%.

[0095] The fermentation broth obtained in Example 3 was detected, and the results obtained are shown in Table 10 and Table 11.

[0096] Table 10 fermentation broth detection data

[0097]

[0098] Table 11 Wet weight of fermentation broth

[0099]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com