Machining center cutter fault automatic protecting mechanism

An automatic protection, machining center technology, applied in the direction of metal processing machinery parts, metal processing, manufacturing tools, etc., can solve the problem of easy damage of machining center tools, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

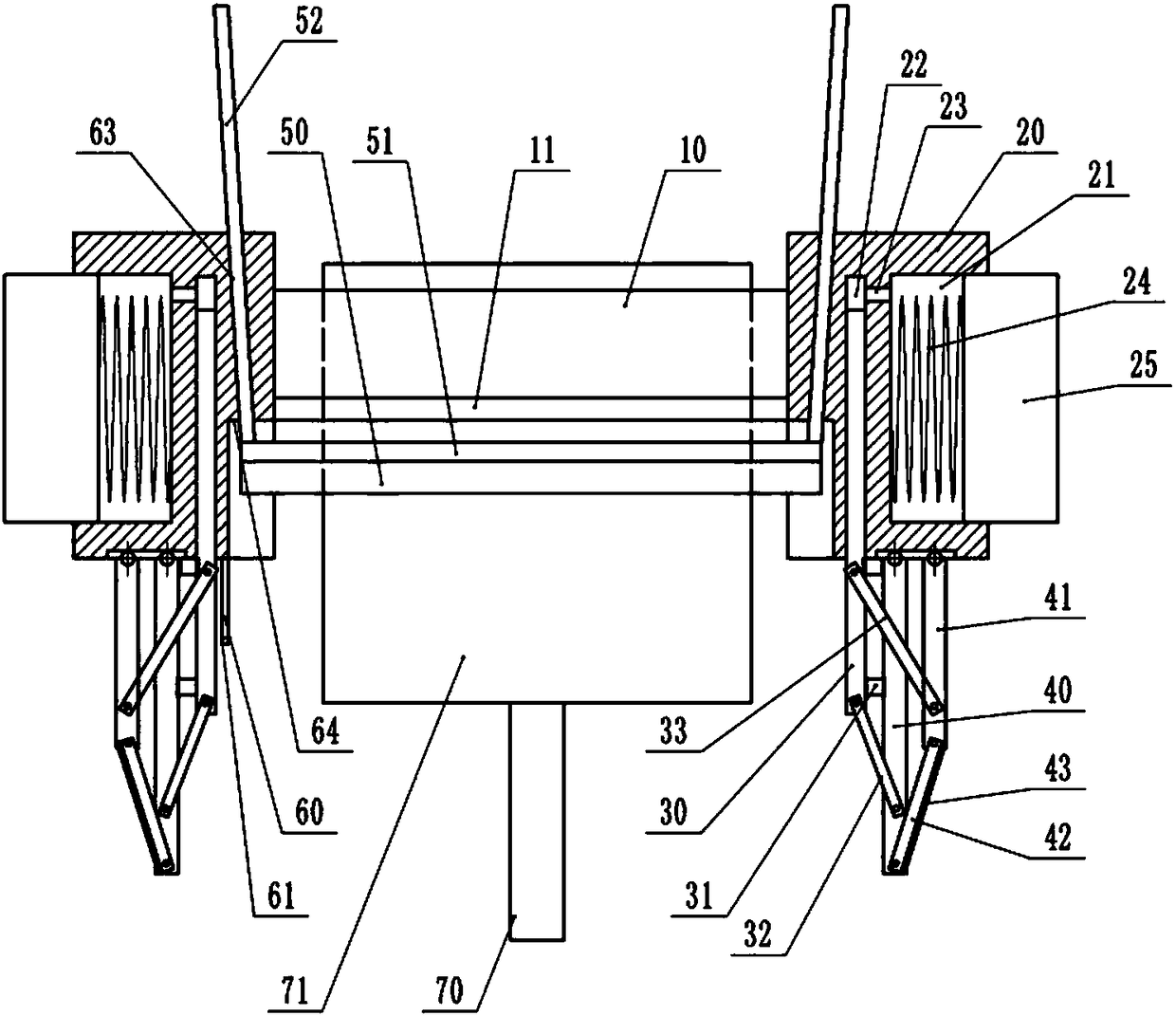

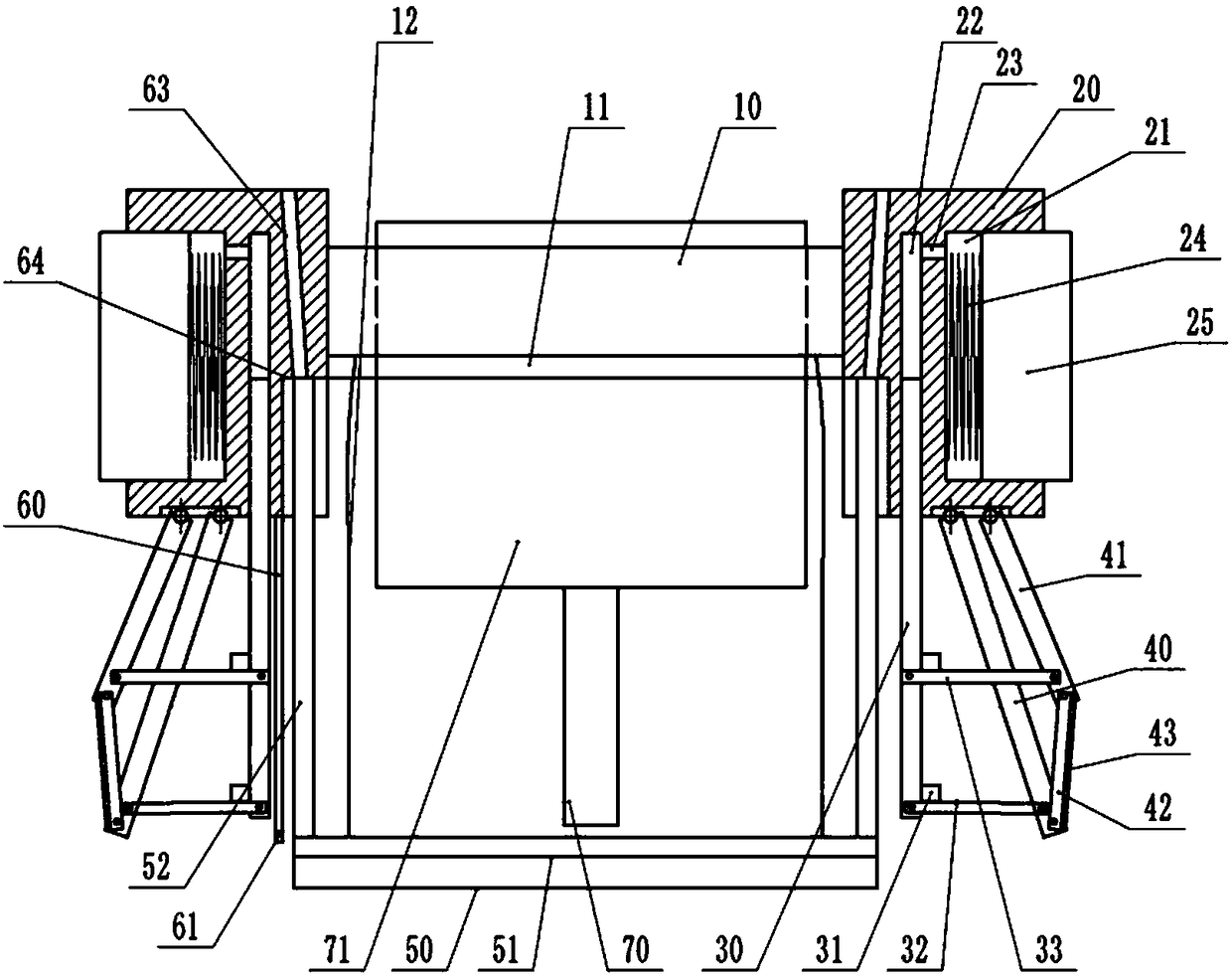

[0023] The reference signs in the accompanying drawings include: elastic fixing belt 10, magnetic block 11, elastic rope 12, bottom block 20, cavity 21, cavity 22, channel 23, elastic member 24, pressing block 25, push plate 30, Limiting block 31, first pole 32, second pole 33, first support plate 40, second support plate 41, support block 42, elastic support pad 43, protection support ring 50, electromagnet 51, slide bar 52, Telescopic rod 60, switch 61, inclined hole 63, groove 64, cutter 70, cutter holder 71.

[0024] Such as figure 1 , figure 2 As shown, the tool failure automatic protection mechanism of the machining center includes an elastic fixing belt 10 for fixing on the tool holder 71. A plurality of anti-collision units are arranged on the elastic fixing belt 10. In this embodiment, there are four anti-collision units. The four anti-collision units are eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com